A process for cold-rolling and extruding teeth on the end face of a cylinder

A cylinder and end face technology, applied to components with teeth, gear tooth manufacturing tools, gear teeth, etc., can solve the problems of high labor density for operators, large processing investment, uneven teeth, etc., and achieve good market prospects, Small processing investment and uniform tooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

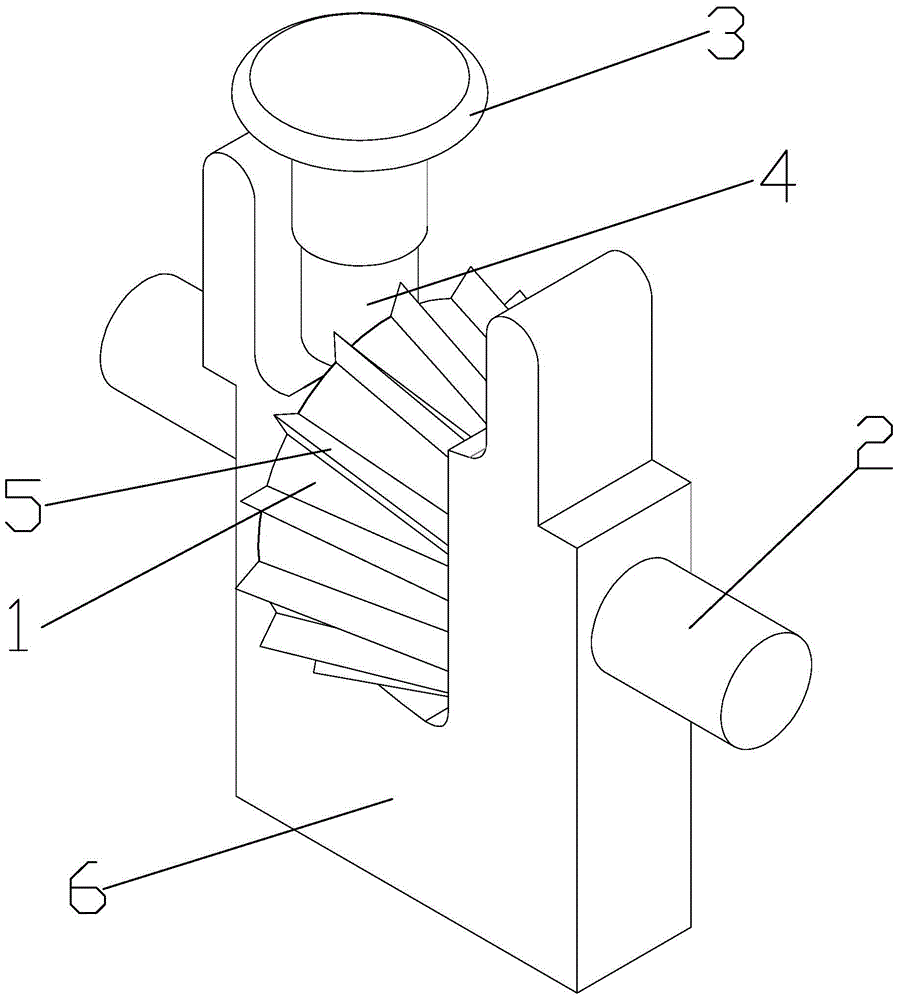

[0017] Such as figure 1 and figure 2 As shown, the process of cold rolling and extruding the end face of the cylinder of the present invention comprises the following steps:

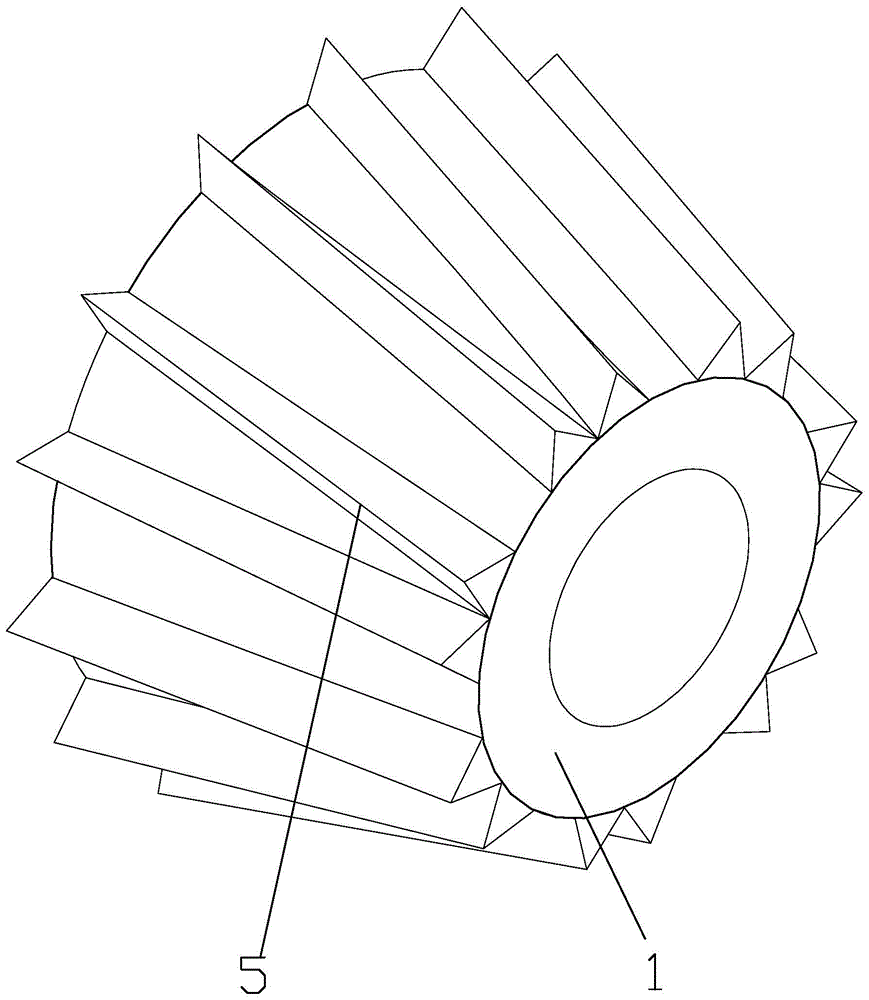

[0018] (1) Prepare the rolling tool 1: the rolling tool 1 is a hollow round table made of alloy steel, with very high strength, and the outer surface of the rolling tool 1 is processed by wire cutting with a rack-shaped blade 5 and a blade 5 5 are connected end to end;

[0019] (2) Fix the workpiece 4 to be processed in the fixture 3 of the lathe, insert the rolling tool 1 on the tool bar 2, and fix the tool bar 2 on the carriage 6, and adjust the position of the tool bar 2 to 10° -60°, the specific position can be selected according to the needs of the workpiece;

[0020] (3) Start the machine tool, adjust the speed of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com