Stepped multi-cutter continuous boring device and machining method for lathe

A stepped and lathe technology, applied in the direction of boring/drilling devices, metal processing equipment, manufacturing tools, etc., can solve the problems of poor processing accuracy, high processing cost, and increased cumulative error, so as to reduce processing cost and improve processing accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

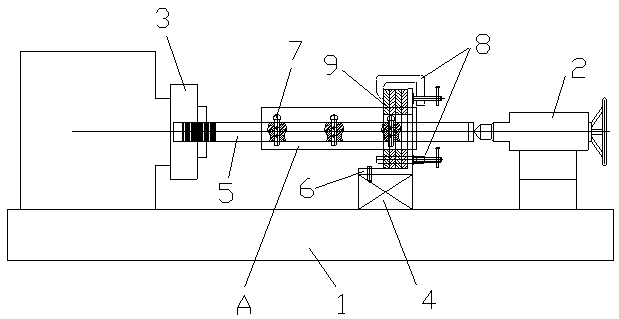

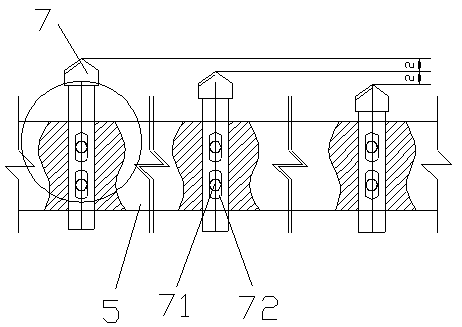

[0018] Example figure 1 and figure 2 As shown, the stepped multi-cutter continuous boring device for a lathe of the present invention includes a lathe frame 1, a lathe spindle power box 2, a lathe tailstock 3, a lathe slide box 4 and a main shaft 5, and the lathe spindle power box 2 and the lathe tailstock 3 are respectively arranged at the two ends of the lathe frame 1, and the main shaft 5 is arranged between the lathe spindle power box 2 and the lathe tailstock 3 and is driven to rotate by the lathe spindle power box 2. The lathe slide box 4 is arranged on the lathe frame 1 and moves along the main shaft 5. The device also includes a positioning plate 6 and a plurality of boring tools 7. The positioning plate 6 is arranged on the top surface of the lathe slide box 4. , the plurality of boring tools 7 are arranged at intervals on the main shaft 5 and the distance between the tool heads of the plurality of boring tools 7 is sequentially increased to the designed aperture of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com