Swing grinding device and method for special-shaped workpiece

A special-shaped workpiece, swing grinding technology, applied in the direction of grinding drive device, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of complicated calculation relationship and relative relationship that is not easy to understand intuitively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

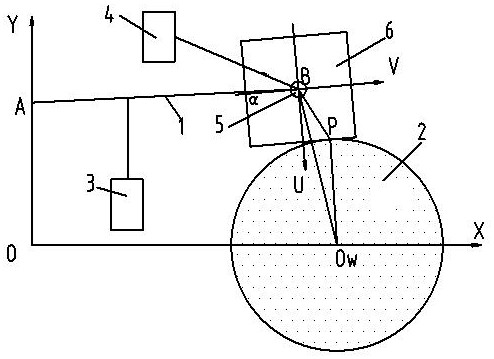

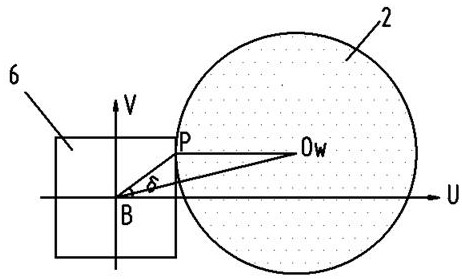

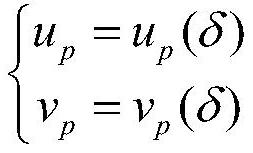

[0034] Example figure 1 As shown, the swing grinding device for special-shaped workpieces of the present invention includes a swing arm 1 that swings at point A, a grinding wheel 2, a lift drive mechanism 3, a swing drive mechanism 4, and a workpiece fixing shaft 5. The lift drive mechanism 3. Drive the swing arm 1 to rotate and swing around the fixed point A. The workpiece fixing shaft 5 is used to install the special-shaped workpiece 6 and is arranged at the front end of the swing arm 1. The rotary driving mechanism 4 drives the workpiece fixing shaft 5 to rotate , the workpiece fixing shaft 5 is concentric with the center of rotation of the special-shaped workpiece 6, while the lifting drive mechanism 3 drives the swing arm 1 to swing, the rotary drive mechanism 4 drives the workpiece fixing shaft 5 to make the special-shaped workpiece 6 rotate continuously, The grinding wheel 2 rotates and grinds the contour shape of the special-shaped workpiece 6 .

[0035] Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com