Ultralarge roller and machining method

A processing method and ultra-large technology, applied in the processing of large drums, super-large drums and processing fields, can solve the problems of low processing equipment and site requirements, high processing equipment and site requirements, and the inability to guarantee the coaxiality of both ends of the drum, etc. , to achieve the effect of reducing processing input, reducing processing input costs, and lower requirements for processing sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

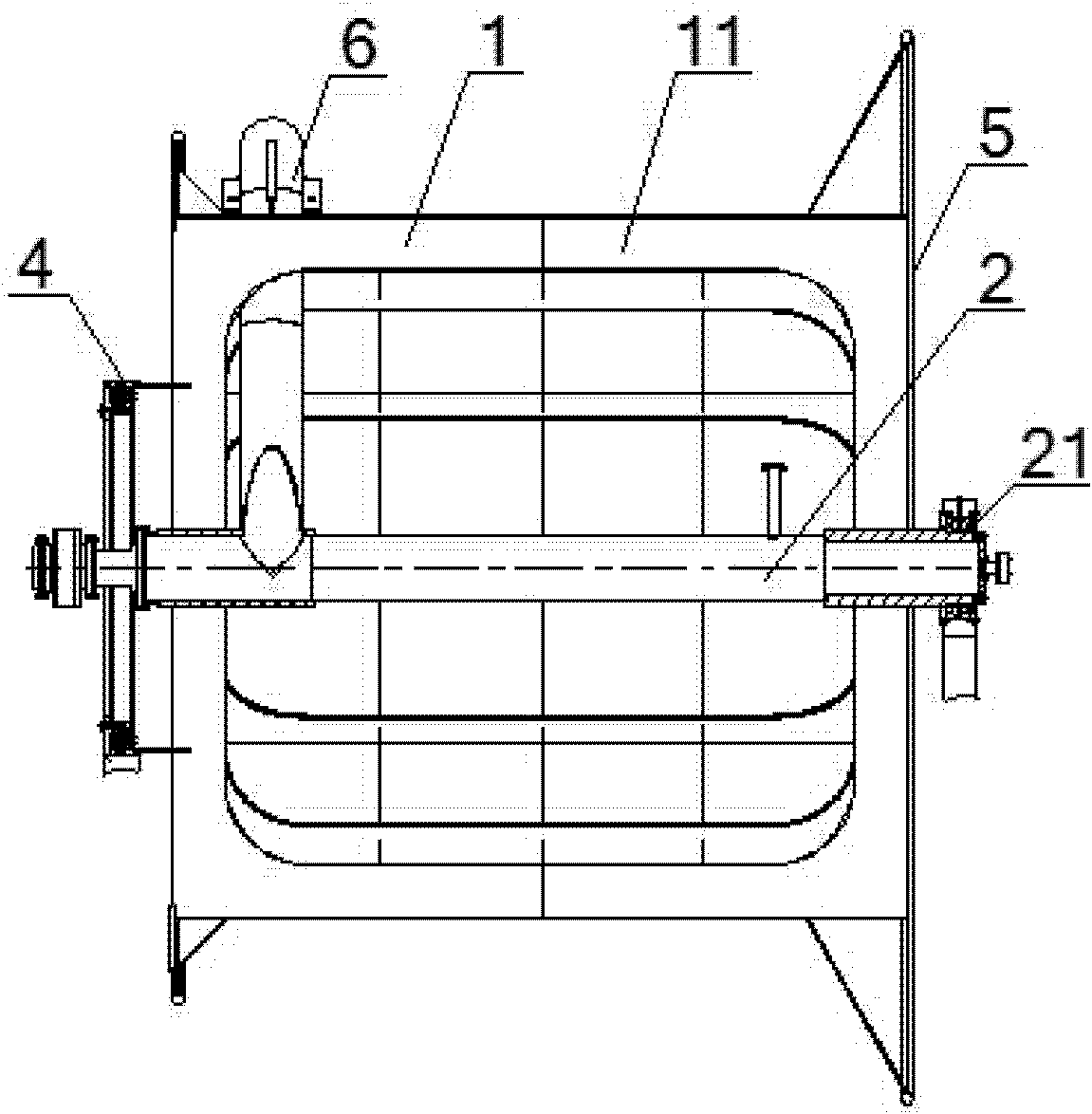

[0033] see figure 1 , figure 2 , super-large drum and processing method, the method comprises the following steps in turn:

[0034] Machining the drum shaft: adopt a vertical lathe to process the bearing mounting position 21 located at the 2-end of the drum shaft;

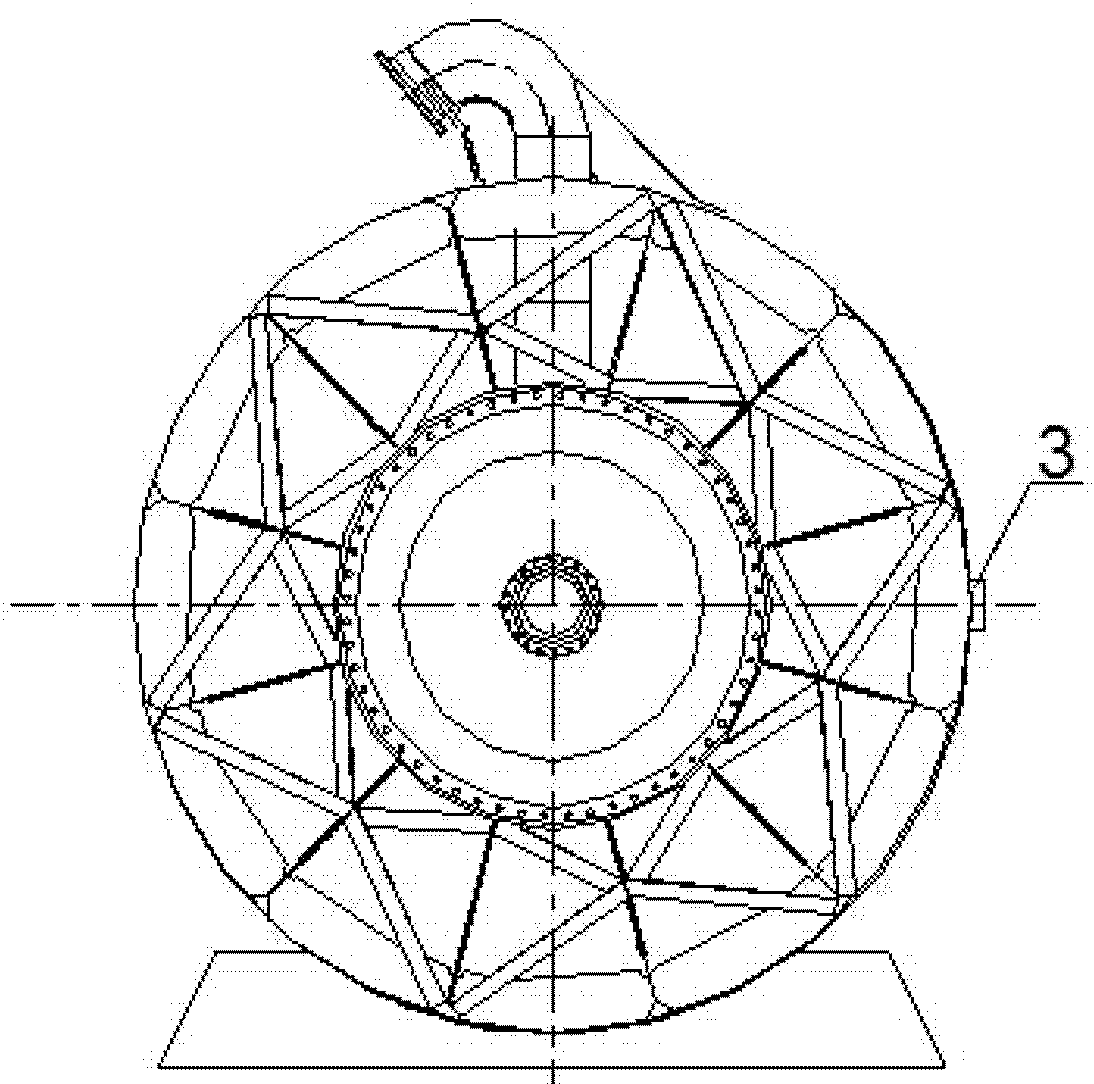

[0035] Install the drum body: the drum body 1 includes a plurality of sub-cylinders 11 with equal diameters. When installing, first set a support ring inside the to-be-joined end of the sub-cylinders 11, and then set the adjacent sub-cylinders 11 on the drum Coaxial docking is performed after the outside of axis 2. Welding reference block: Use a boring machine to weld the reference block 3 in the center of the side of the drum body 1. The upper and lower reference planes of the reference block 3 are arranged symmetrically with the center of the drum shaft 2. The straight reference planes of the reference block 3 are aligned with the upper and lower Datum vertical setting;

[0036] Machining the installation po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com