Outer diameter and tooth profile progressive extruding screw tap for trapezoidal inner threads

A technology for extruding taps and internal threads, used in thread cutting tools, metal processing equipment, tangent devices, etc., can solve problems such as inability to process trapezoidal internal threads with high service life, and achieve the effect of improving fatigue resistance and surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1-1 to Figure 3-2 shown.

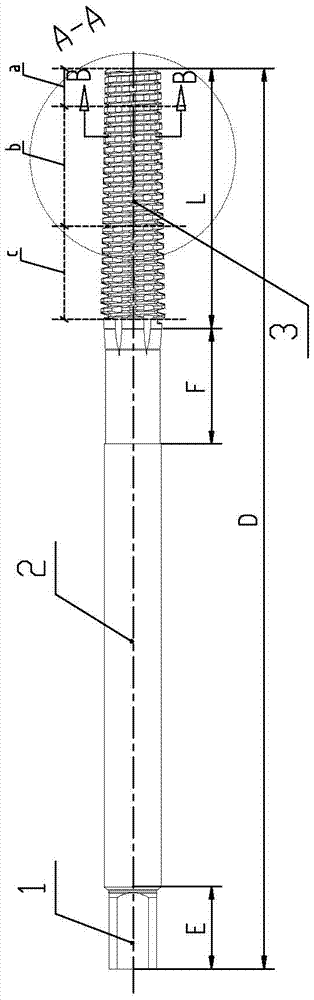

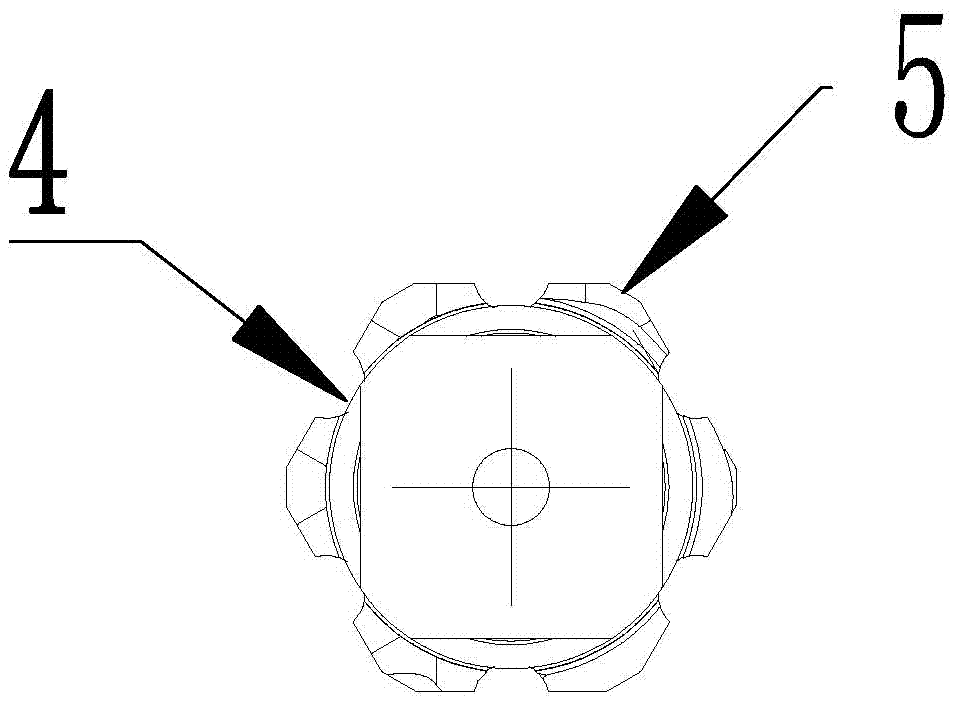

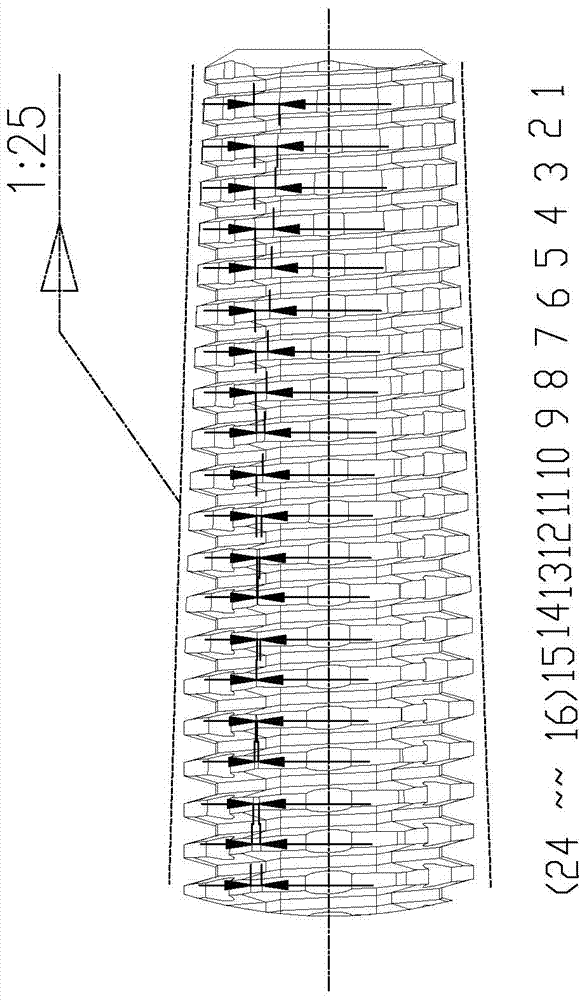

[0024] A progressive extruding tap with external diameter and tooth shape for trapezoidal internal thread, which includes a tap clamping end 1, a tap rod body 2 and a tap extruding body 3, such as Picture 1-1 As shown, the tap extrusion body 3 includes a guide part a, an extrusion part b and a correction part c, and the length of the guide part a accounts for 10-20% of the length of the entire tap extrusion body 3, preferably 16%. The length of the extrusion part b accounts for 44-52% of the length of the entire tap extrusion body 3, the best being 48%, and the length of the correction part c accounts for 32-40% of the length of the entire tap extrusion body 3, the best being 36% ; A circle of extrusion ribs is provided between adjacent two circles of extrusion teeth of the tap extrusion body 3, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com