Micro-bend intensity modulated type optical fibre sensor

An optical fiber sensor, intensity modulation technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of insufficient accuracy, small application range, high working environment requirements, etc., and achieve high measurement accuracy, low price, visual good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

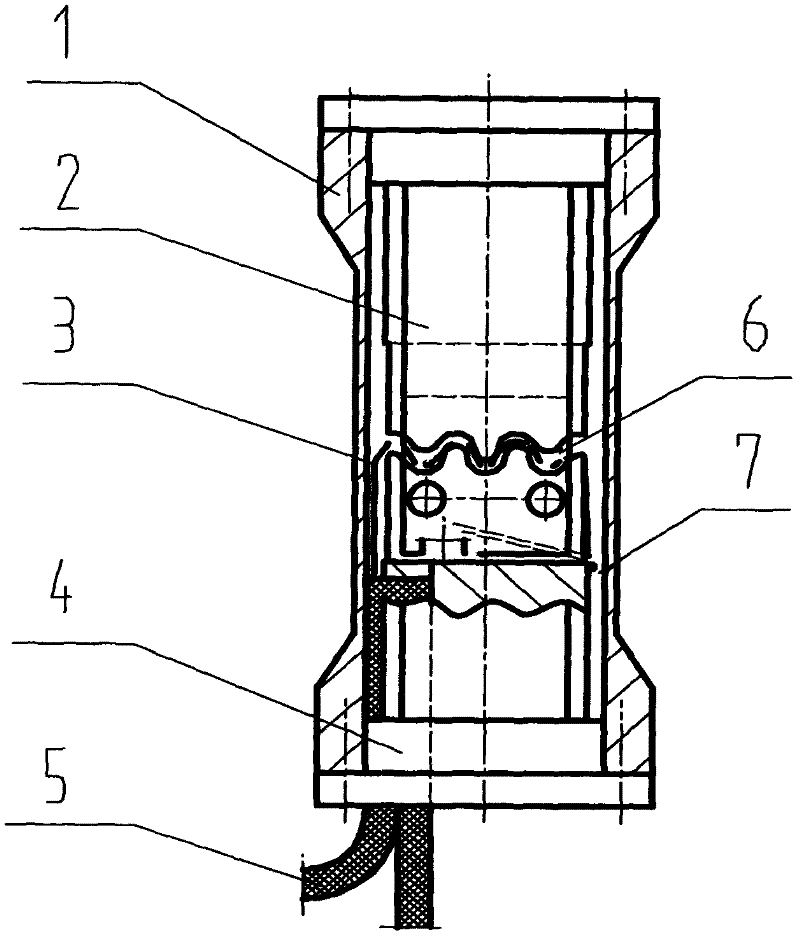

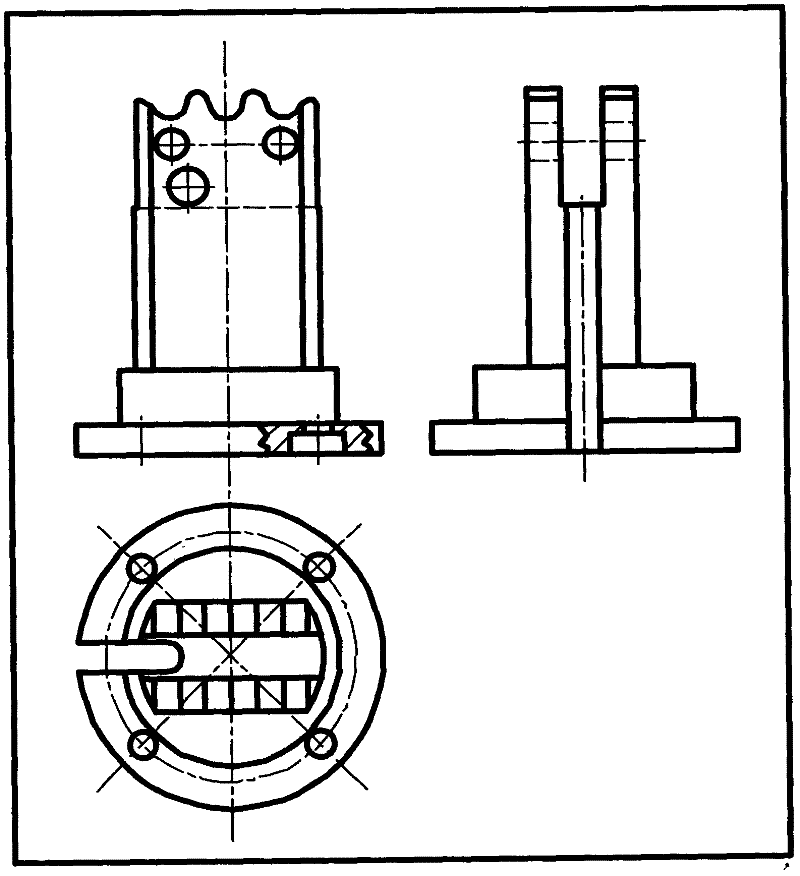

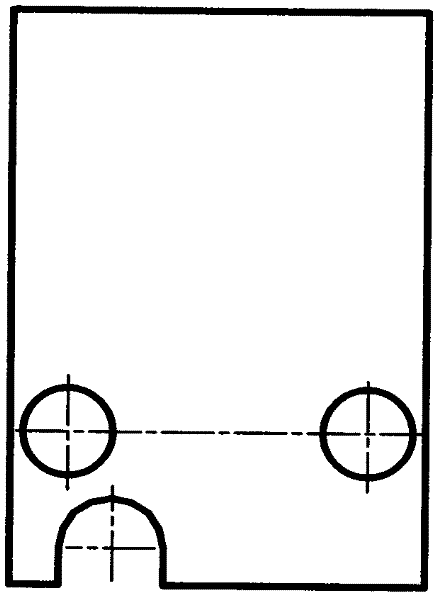

[0025] The sensor consists of three parts: an elastic element, a microbend and an optical fiber length compensation device.

[0026] Elastic elements can be divided into elastic support elements and elastic sensitive elements. Elastic support elements only play the role of force transmission and force, and their deformation is not included in the effective deformation. Elastic sensitive elements not only play the role of force transmission and force, but also their Deformation is an effective deformation. The latter is adopted in this design, and the sleeve 1 is used as an elastic sensitive element, which not only plays the role of force transmission and stress, but also its deformation is effective deformation.

[0027] The microbender is composed of a microbender upper piece 2 and a microbender lower piece 4 . In order to ensure that the microbender can meet the requirements of a certain number of working teeth and not oversize, a double row of extrusion teeth is used to pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com