olive crushing and grinding equipment

A technology of crushing, grinding and oiling olives, which is applied in the direction of fat oil/fat production, fat production, grain processing, etc., and can solve the problems of destroying the active ingredients of olive oil and affecting the quality of olive oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

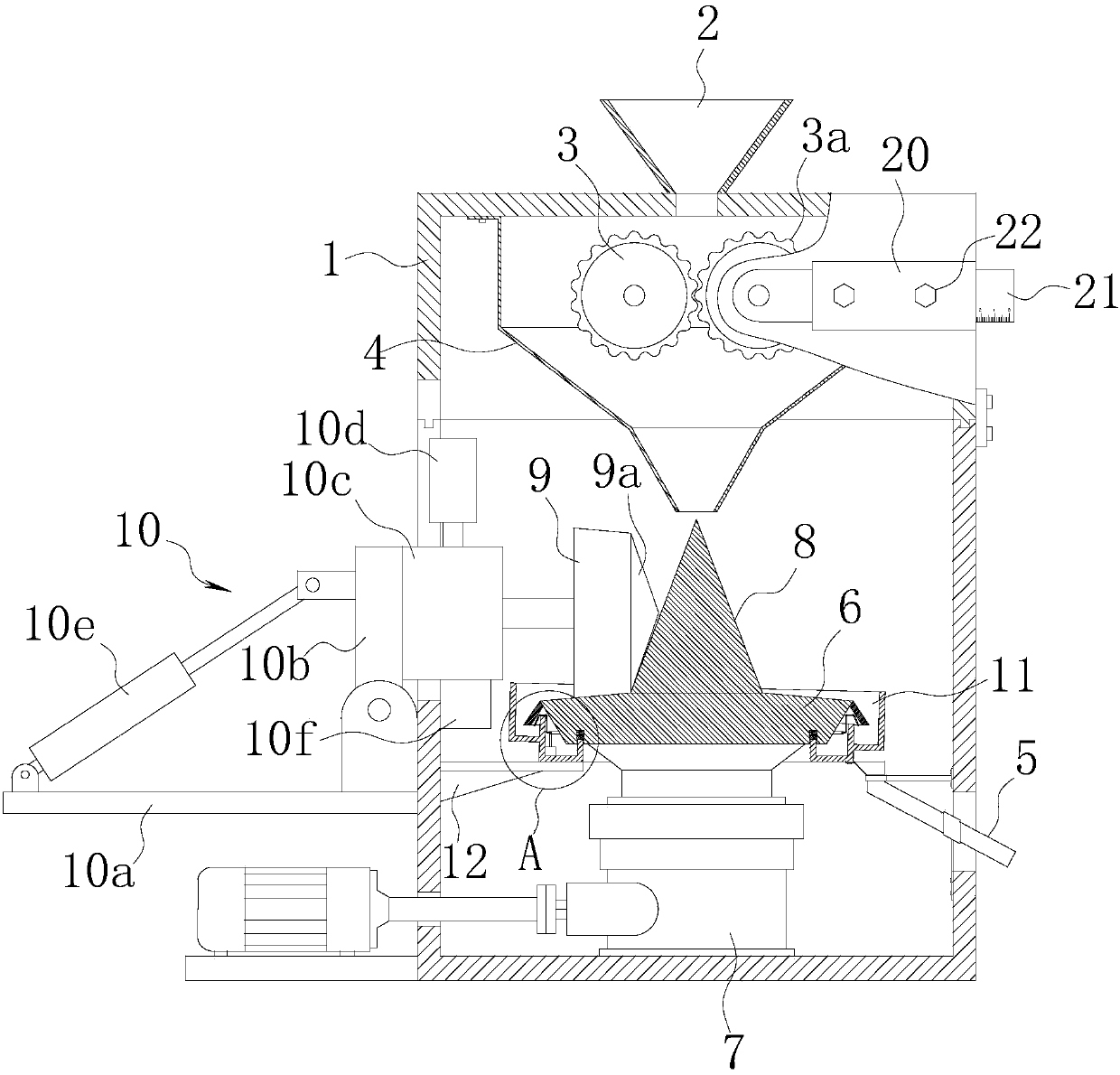

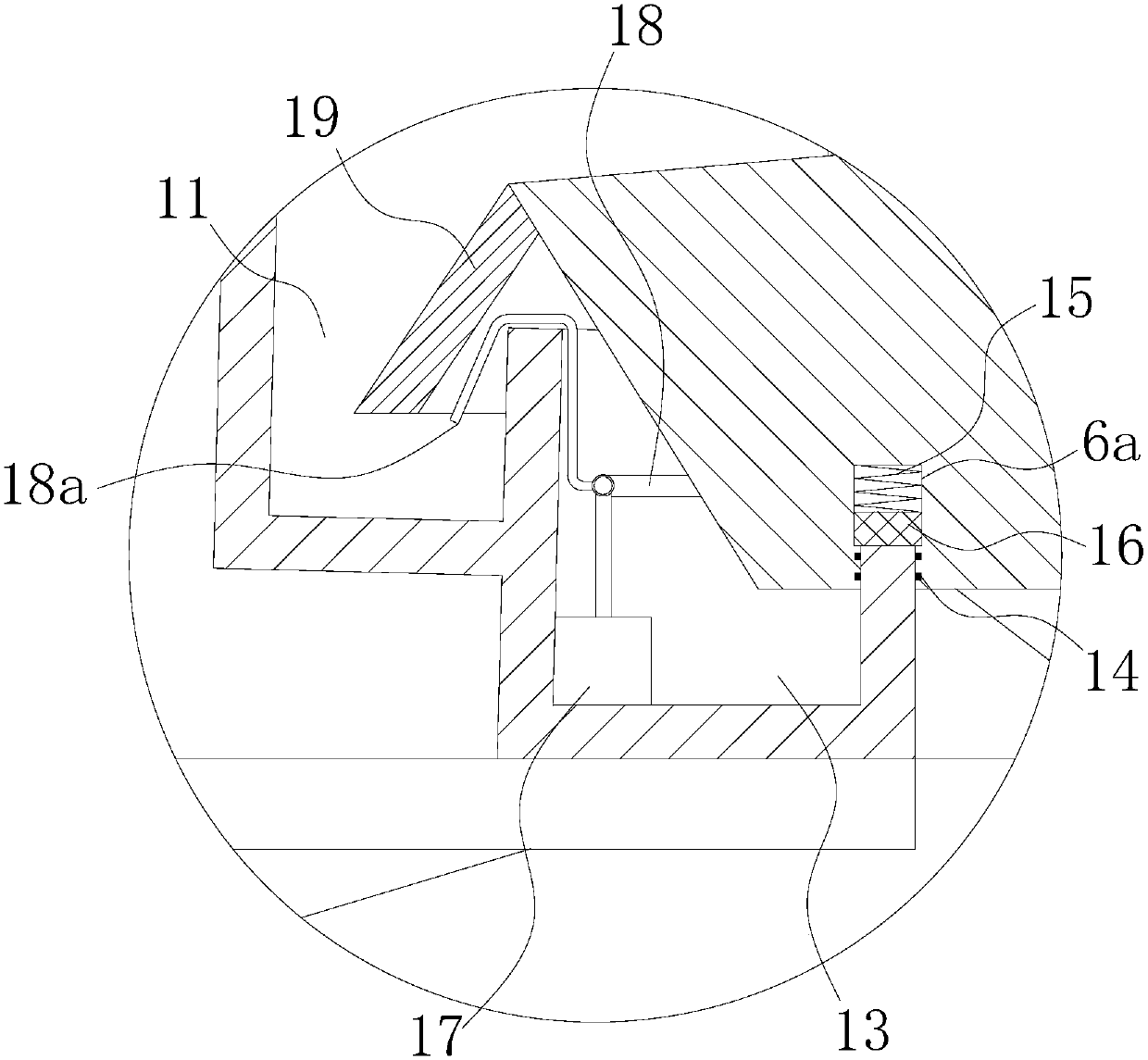

[0020] refer to figure 1 and figure 2 As shown, a kind of olive crushing and grinding equipment of the present invention includes a casing 1, which is composed of upper and lower parts, which is convenient for disassembly, maintenance and cleaning. An opening is provided on the top of the casing 1, a hopper 2 is provided at the opening, and two squeeze rollers 3 that cooperate with each other are arranged on the upper part of the casing 1. The two squeeze rollers 3 are respectively connected with a rotary drive motor and two The rotating speed of extrusion roller 3 is 0.5~2r / s; The surface of two extrusion rollers 3 is provided with a plurality of extrusion teeth 3a along the circumferential direction, between two adjacent extrusion teeth 3a cooperate to form extrusion groove, extrusion tooth There is a smooth transition between 3a and the extrusion groove. In this embodiment, the inner contour of the extrusion groove is the same as the outer contour of the extrusion tooth 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com