Motor excitation coil insulating layer breaking device

A technology of motor excitation and insulating layer, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of inconvenience and complexity of motor manufacturers, avoid irregularities and inconsistencies, improve efficiency, and solve cumbersome processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

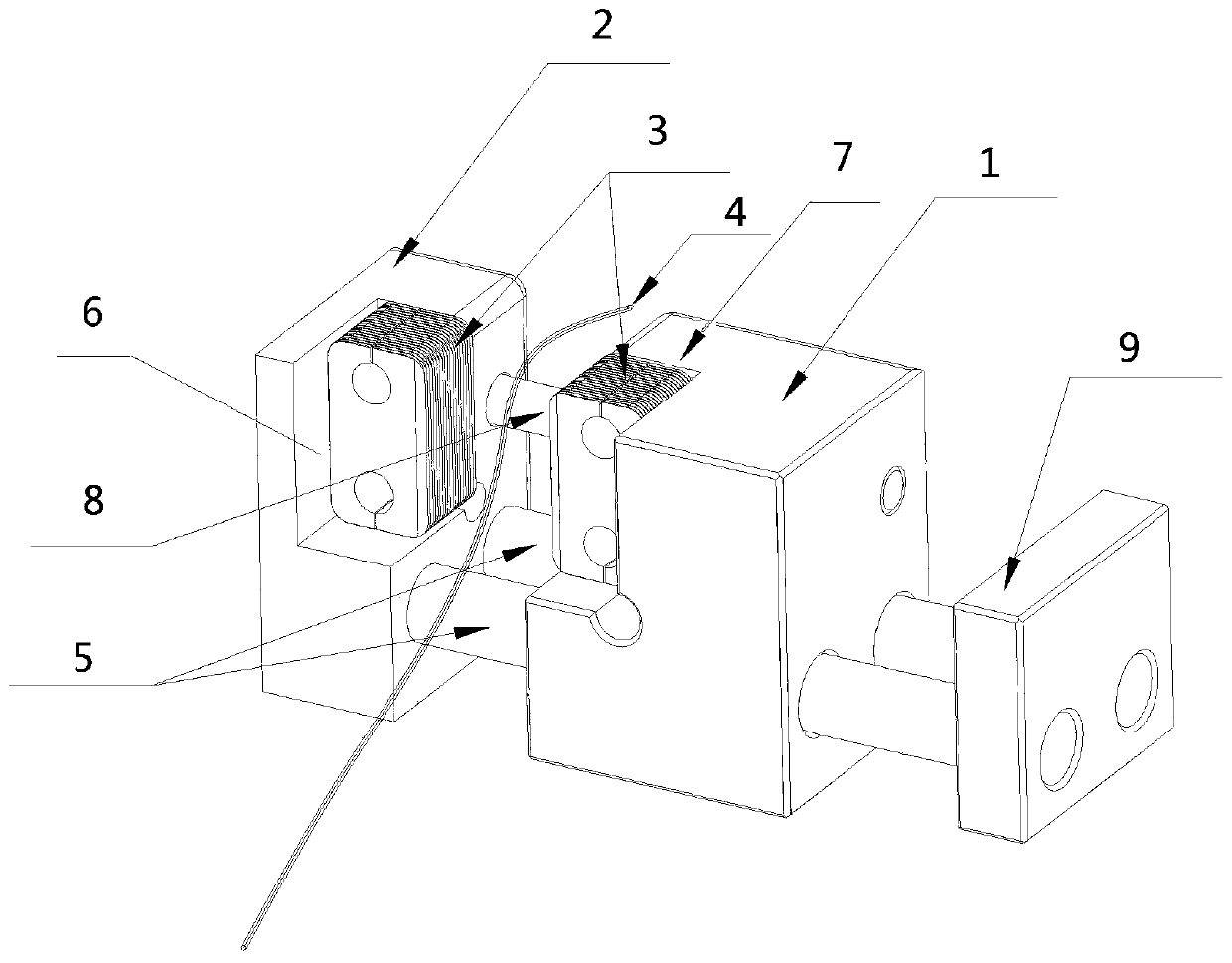

[0020] Such as figure 1 The shown device for breaking the insulating layer of a motor excitation coil includes a fixed clamp block 1, a movable clamp block 2, and extrusion teeth 3 respectively fixed on the opposite surfaces of the fixed clamp block 1 and the movable clamp block 2, and the extrusion teeth 3. Power on; specifically, during installation, the fixed clip 1 and the movable clip 2 are rectangular, which is convenient for installation and layout. At the same time, the fixed clip 1 is fixedly installed on the stator winding machine during installation. The movable clamping block 2 is movably set on the stator winding machine, and can move relative to the fixed clamping block 1, so as to ensure that the extrusion teeth on the corresponding surfaces of the fixed clamping block 1 and the movable clamping block 2 can be squeezed against each other. The insulation layer of the wire 4 between the fixed clamp block 1 and the movable clamp block 2 is crushed to facilitate ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com