Extrusion type steel pipe cutter and fabrication method thereof

A production method and extrusion technology, which is applied to pipe shearing devices, manufacturing tools, knives for shearing machine devices, etc., can solve the problems of unusable cutting knives, explosion of pipes, and inability to cut steel pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

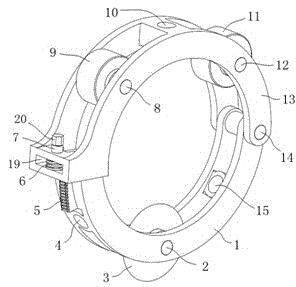

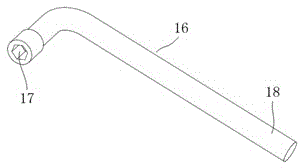

[0015] Embodiment of the present invention: a manufacturing method of an extruded steel pipe cutter, the method adopts a circular cutter blade to be assembled on the lower tool holder through the blade shaft, the roller one is assembled on the upper tool holder through the roller shaft, and the roller two The roller shaft 2 is assembled on the upper knife rest, the extrusion wheel is assembled on the extrusion shaft, and the lower end surface of the extrusion wheel is attached to the bottom surface of the extrusion groove of the upper knife rest, and the extrusion shaft is assembled on the upper knife rest, and The upper teeth of the extrusion wheel mesh with the extrusion teeth on the lower tool holder, and the working end of the plunger is in clearance fit with the upper shelf socket of the upper tool holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com