Energy-saving roller type grading machine

A grading machine and roller technology, which is applied in the field of crushing and processing devices for solid materials, can solve the problems of low pollution and low power loss, and achieve the effects of small vibration, reasonable structure and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

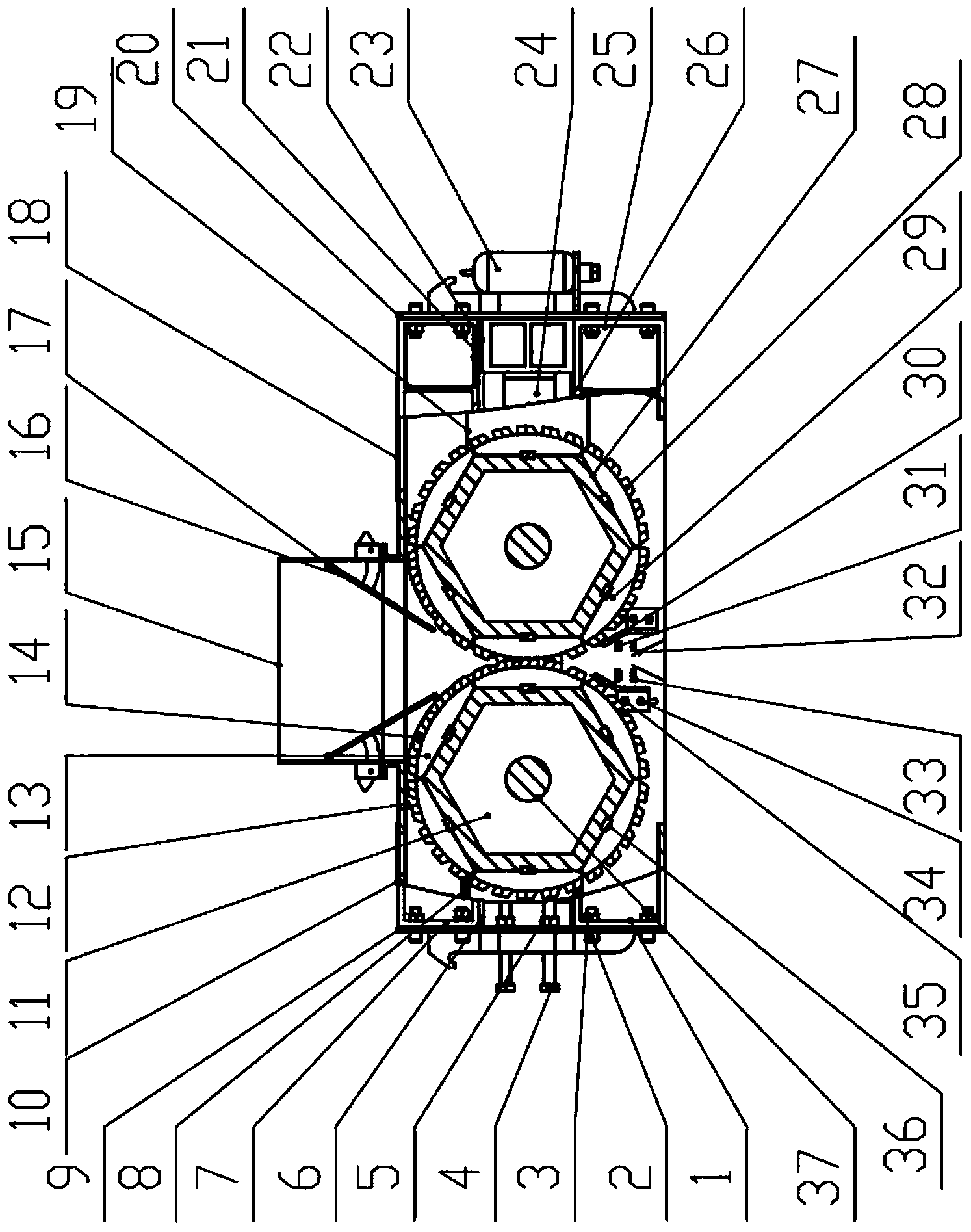

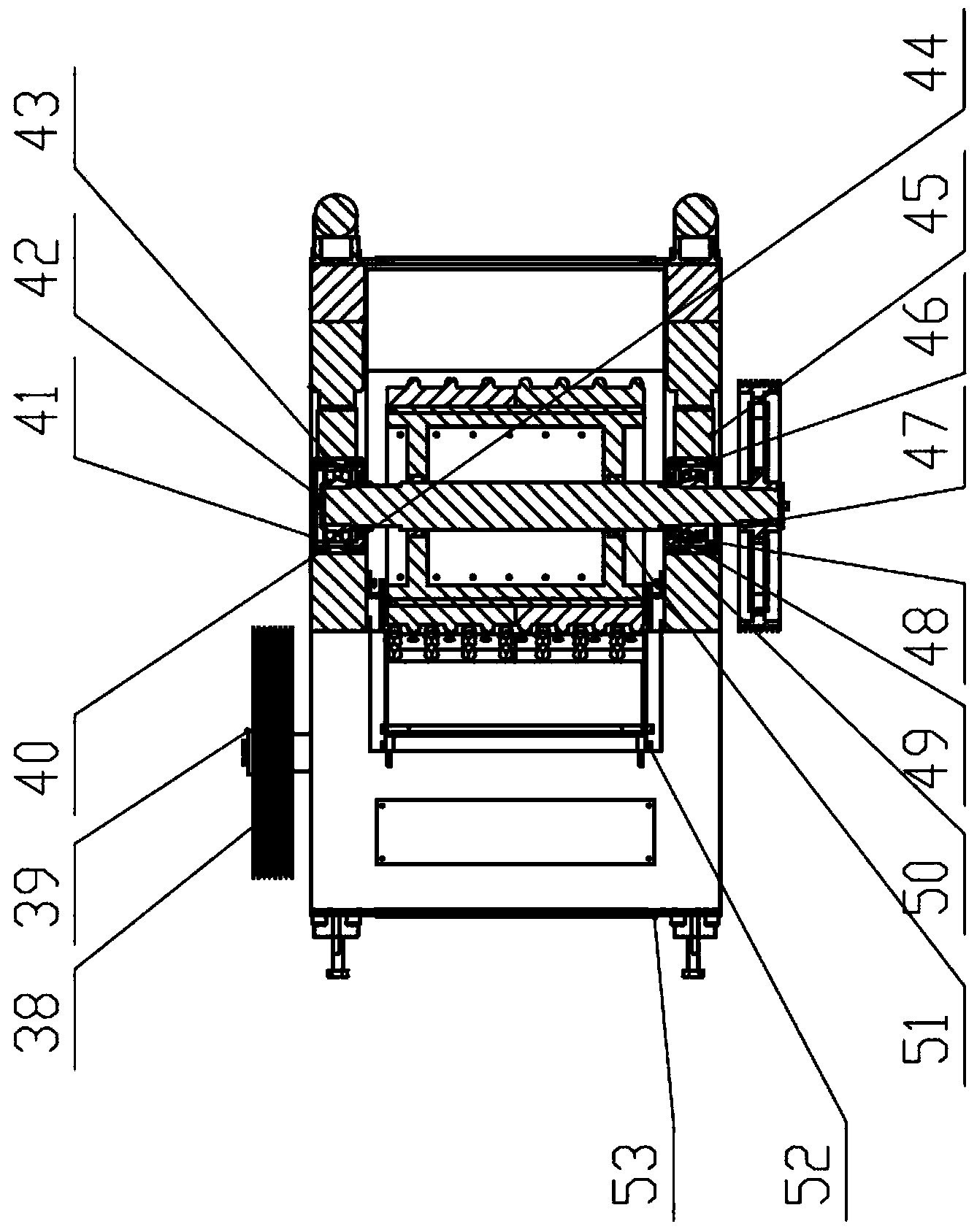

[0029] The invention discloses an energy-saving roller grading machine. For details, please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 .

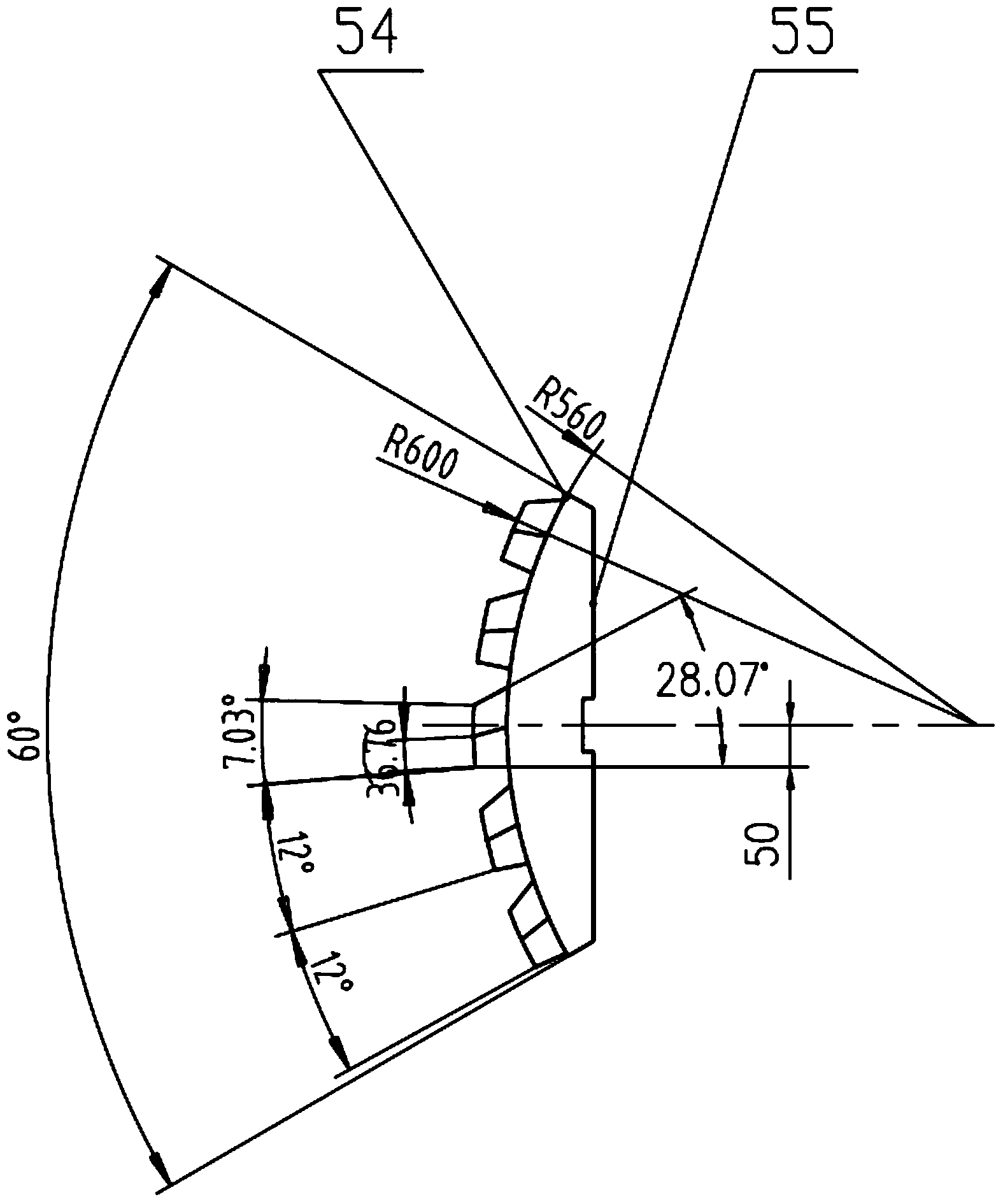

[0030] As shown in the figure: the main engine is driven by a motor, the motor is connected to the pulley, the pulley is installed on the main shaft, the bearing seat 43 is fixed on the frame 1, the main shaft 37 is installed on the bearing seat 43, and the crushing extrusion roller 11 is installed on the main shaft 37. The specially designed crushing and squeezing roller 11 is composed of a hexagonal rotor 27, the first wear-resistant tooth plate 13 or the second wear-resistant tooth plate 29, and the first wear-resistant tooth plate 13 and the second wear-resistant tooth plate 29 are respectively uniformly installed. There are shear teeth 14 and extrusion teeth 28 . Wherein, the crushing extrusion roller 11 equipped with the first wear-resistant tooth plate 13 and the second wear-resistant tooth plate 29 forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com