Novel rubbish waste recovery extrusion device

A technology of extrusion device and waste waste, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to extrude, loose garbage, complex structure of the extrusion device, etc., and achieve the effect of strong wear resistance and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

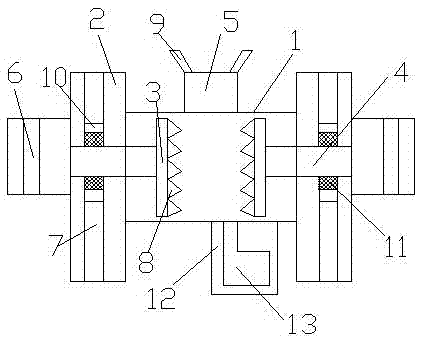

[0012] A new type of rubbish recycling extrusion device, comprising a housing 1 and an extrusion device 2, the housing 1 is connected with the extrusion device 2, the extrusion device 1 is respectively installed on both sides of the housing 1, and the extrusion device 2 is An extrusion plate 3 and a push rod 4 are provided. The extrusion plate 3 and the push rod 4 extend into the housing 1. The housing 1 is provided with a feeding port 5. The extrusion plate 3 moves left and right under the drive of the push rod 4. The extrusion device 2 also includes a propulsion motor 6. The propulsion motor 6, the propulsion rod 4 and the extrusion plate 3 form a whole. , the extrusion device 2 is hollowed out up and down, the positioning rod 7 is located in the hollowed out space, the extrusion plate 3 is provided with occlusal teeth 8, the occlusal teeth 8 are evenly distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com