Extrusion pressure detection device of battery module

A detection device and battery module technology, applied in the direction of measuring devices, auxiliary devices, measuring force, etc., can solve the problems of high fit requirements, poor welding, easily damaged battery poles and pole pieces, etc., to achieve adaptability Good resistance, tight extrusion, and prevent excessive extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

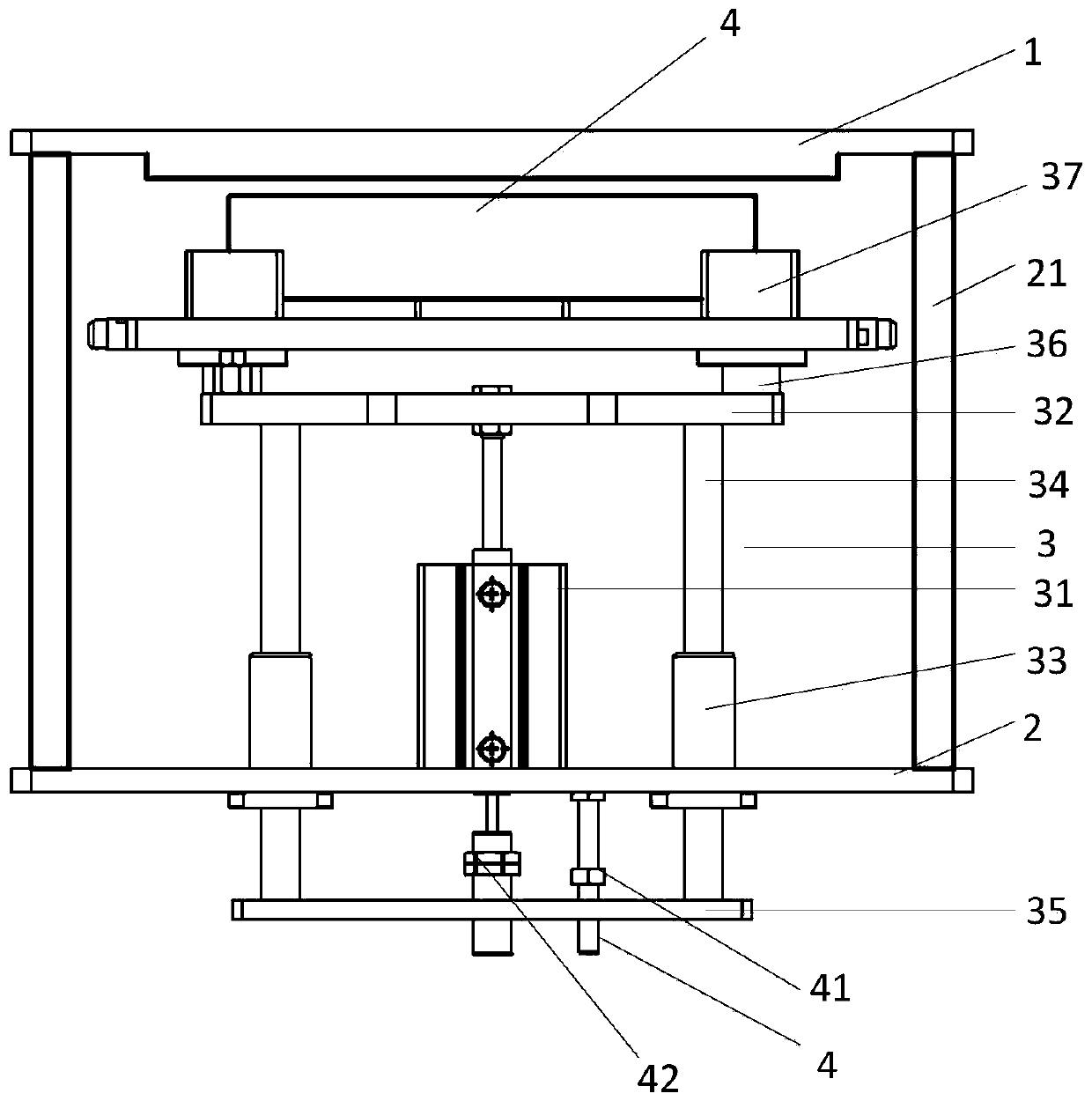

[0016] Such as figure 1 As shown, a battery module extrusion pressure detection device includes a top plate 1, a bottom plate 2 and an extrusion mechanism 3. The upper surface of the bottom plate 2 is provided with pillars 21 respectively, and the tops of the pillars 21 are respectively connected to the top plate 1; the extrusion mechanism 3 It includes a cylinder 31 and an extrusion plate 32. The cylinder 31 is arranged in the center of the upper surface of the bottom plate 2, and the piston of the cylinder 31 is connected to the center of the lower surface of the extrusion plate 32. The cylinder 31 is provided with guide pipes 33 around each of the guide pipes 33. A guide post 34, the top of the guide post 34 is connected to the lower surface of the pressing plate 32, the bottom of the guide post 34 extends below the bottom plate 2 and is connected with a fixing plate 35, and two guide posts 34 are respectively connected to each fixing plate 35; The upper surface of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com