Shell pre-crushing treatment device for decorative material production

A decorative material and processing device technology, which is applied in the field of shell pre-crushing processing devices for decorative materials production, can solve the problems of uneven particle size distribution, affecting processing efficiency, etc., to improve extrusion crushing effect, improve crushing effect, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

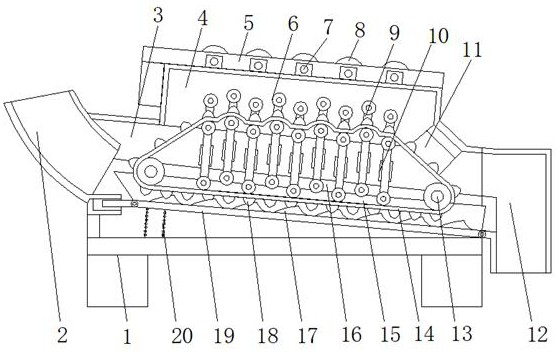

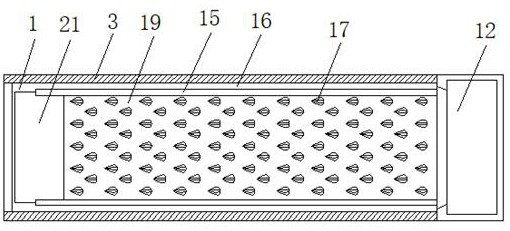

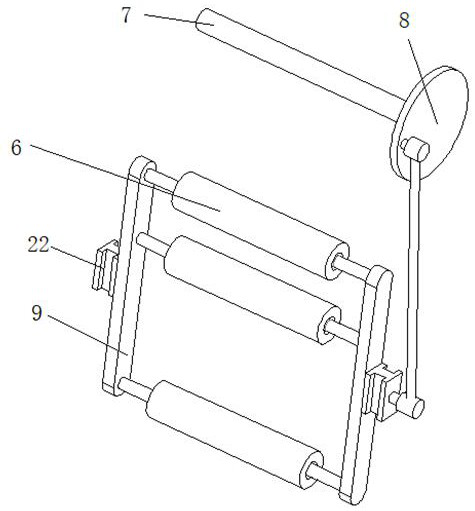

[0027] refer to Figure 1-3 with Figure 5-6 , a shell pre-crushing treatment device for the production of decorative materials, comprising a machine base 1, side plates 3 are fixedly installed on both sides of the top of the machine base 1, and the two side plates 3 and the ends of the machine base 1 are respectively fixed A feed hopper 2 and a discharge hopper 12 are installed, and an end cover 4 is fixedly installed between the tops of the two side plates 3 , and the sides of the two side plates 3 are provided with installation grooves 16 , and between the two installation grooves 16 There is a bottom plate 19 with an inclined distribution, and the two ends of the bottom plate 19 are respectively connected with the feed hopper 2 and the discharge hopper 12, and both sides of the top of the bottom plate 19 are fixedly installed with a limit plate 15, and a bearing is installed between the two side plates 3 Two driving rollers 13, and a crushing chain plate 14 is sleeved bet...

Embodiment 2

[0036] refer to Figure 1-6 , a shell pre-crushing device for the production of decorative materials. Compared with Embodiment 1 in this embodiment, the bottom end of the bottom plate 19 is hinged to the discharge hopper 12, and the top end of the bottom plate 19 is hinged to be slidably connected to the feed hopper 2. Between the transition plate 21, the base plate 19 and the machine base 1, rows of top springs 20 are fixedly installed, and the movable angle between the base plate 19 and the machine base 1 is 5°-10°.

[0037] When this embodiment is in use, when the broken chain plate 14 squeezes the bottom plate 19, or when the shells are piled up, the top of the bottom plate 19 is driven to deflect downward, and the thrust of the top spring 20 is used to make it vibrate continuously, increasing the extrusion tooth block 18 and the impact force between the crushing teeth 17, and then improve the conveying effect and crushing effect of the shell fragments on the top of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com