Gear grinding machine for grinding teeth of circular band saw blade

A technology of endless belts and gear grinding machines, which is applied to tool trimming of sawing machine devices, metal sawing equipment, and metal processing equipment. Simple and smooth action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

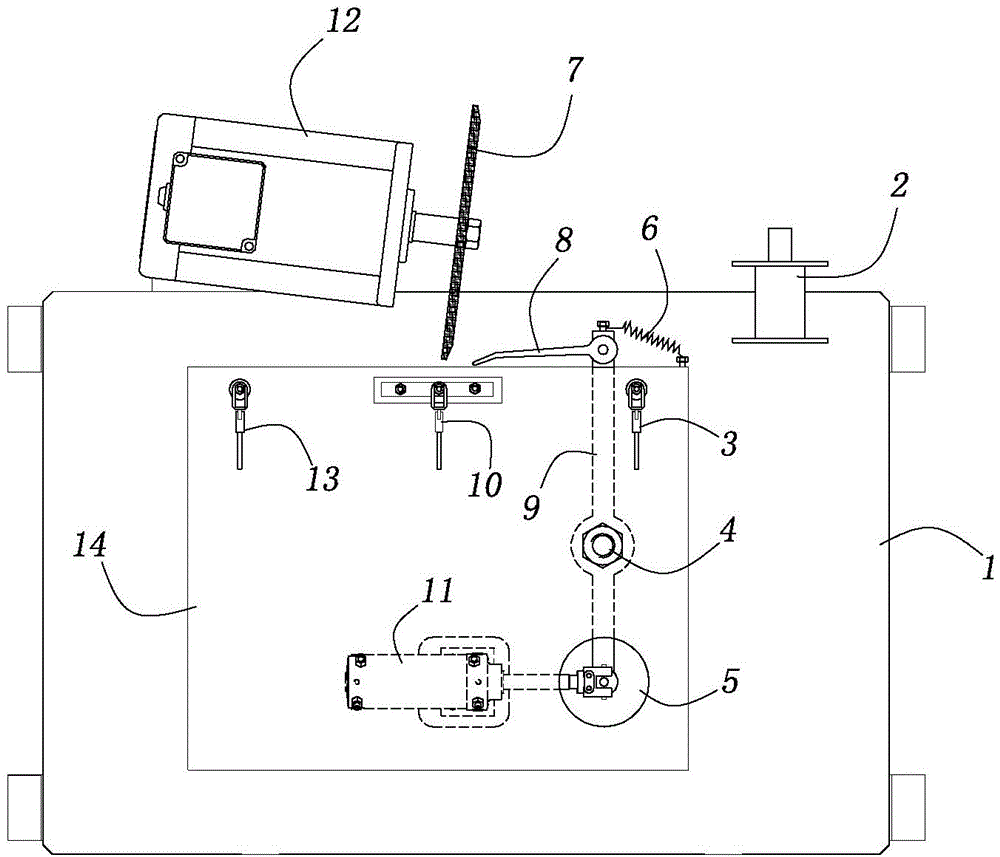

[0010] See figure 1 , the present invention includes a workbench 1 on which a mounting plate 14 is provided through a plurality of spacers.

[0011] A side edge of the mounting plate 14 is provided with a first end clamp 3 , a middle clamp 10 and a second end clamp 13 , and the function of the three clamps is to press the circular band saw blade on the edge of the mounting plate 14 , The compression mentioned here is a slight compression, and the size of the compression force is suitable to ensure that the band saw blade does not move randomly and can move laterally under sufficient external force traction.

[0012] Below the mounting plate 14 is provided with the connecting rod 9 whose middle part is hingedly connected with the mounting plate 14 through the hinge shaft 4, and is also fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com