Multi-stage crushing/grinding/emulsifying colloid mill

A technology of emulsified colloid and rotor, applied in the direction of cocoa, grain processing, food science, etc., can solve the problems of less processing material, infiltration, motor burnout, etc., and achieve the effect of fine grinding and more material output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

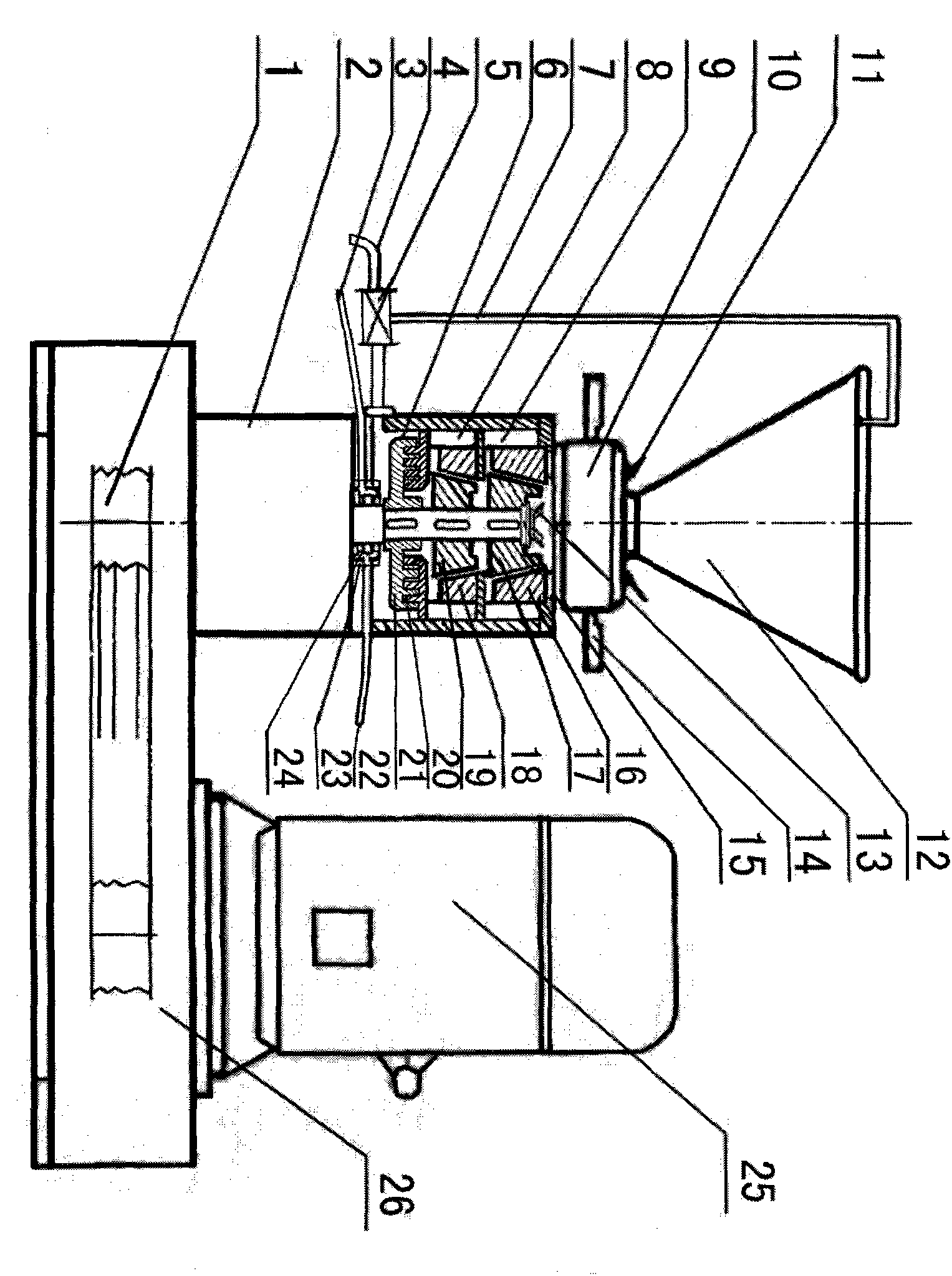

[0009] As attached figure 1 As shown, a main engine 2 and a motor 25 are installed on the base 26. The base 26 is provided with a transmission wheel 1. There are two transmission wheels 1. The main shaft passes through the base 26 to connect to one of the transmission wheels 1, and the motor main shaft passes through The base 26 is connected to another transmission wheel 1, and the two transmission wheels 1 are connected by a belt; the upper part of the housing 15 is provided with an adjusting device 10, and a handle 14 is installed on the adjusting device 10. The handle 14 processes the materials in the adjusting device 10 finely. The cooling water pipe joint 11 is installed on the adjusting device 10 to add cooling water at any time to protect the adjusting device 10; a hopper 12 is set on the top of the adjusting device 10, and the hopper 12 is a cone-shaped stainless steel product; one end of the circulating return pipe 7 is set at Above the hopper 12, the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com