Composite grinding lathe for grinding pin wheel housing

A compound grinding and grinding needle technology, which is applied in the field of grinding processing, can solve the problems of complicated grinding and easy interference in grinding internal tooth grooves, and achieves the effect of convenient operation and guaranteeing of grinding processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

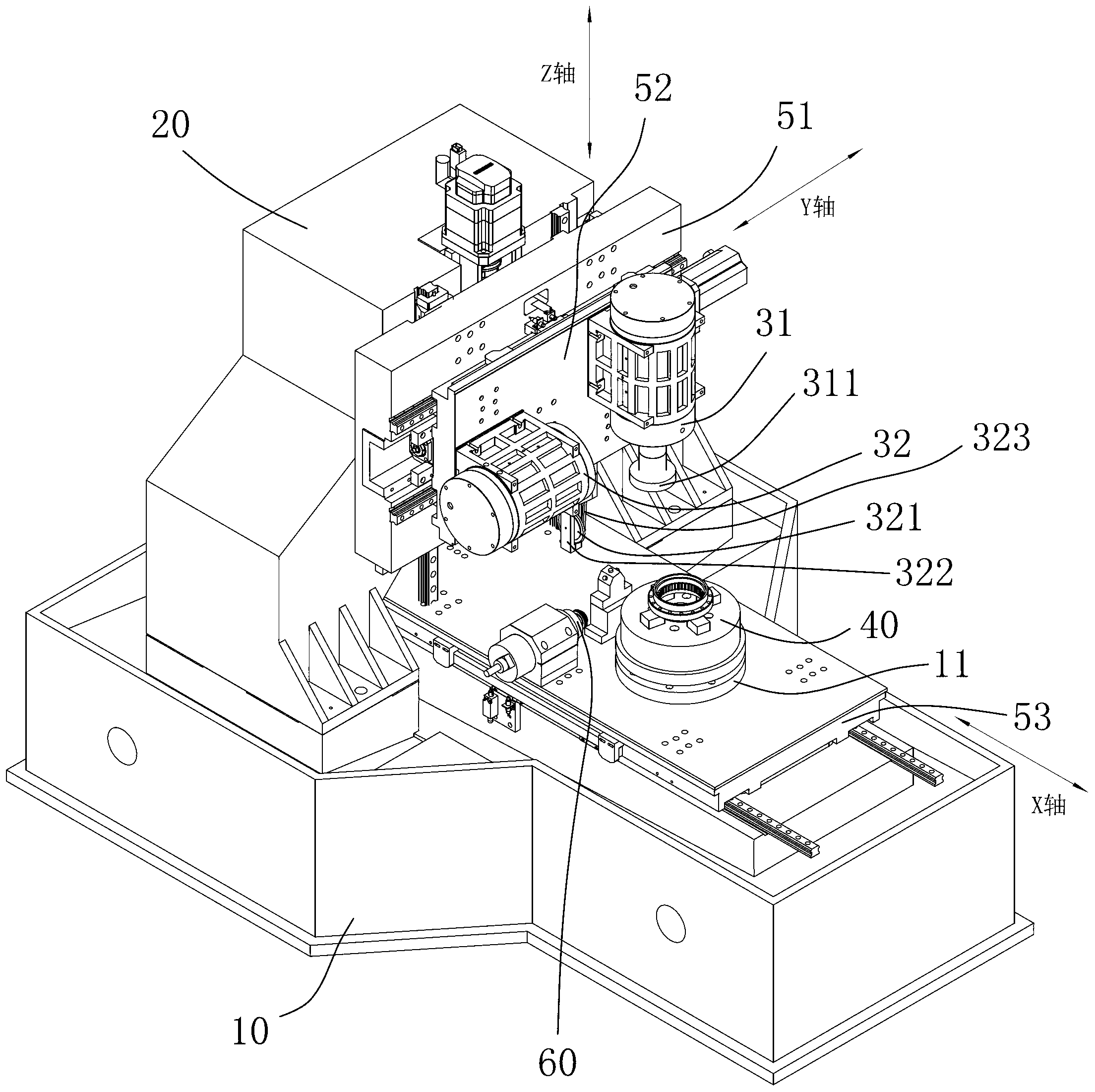

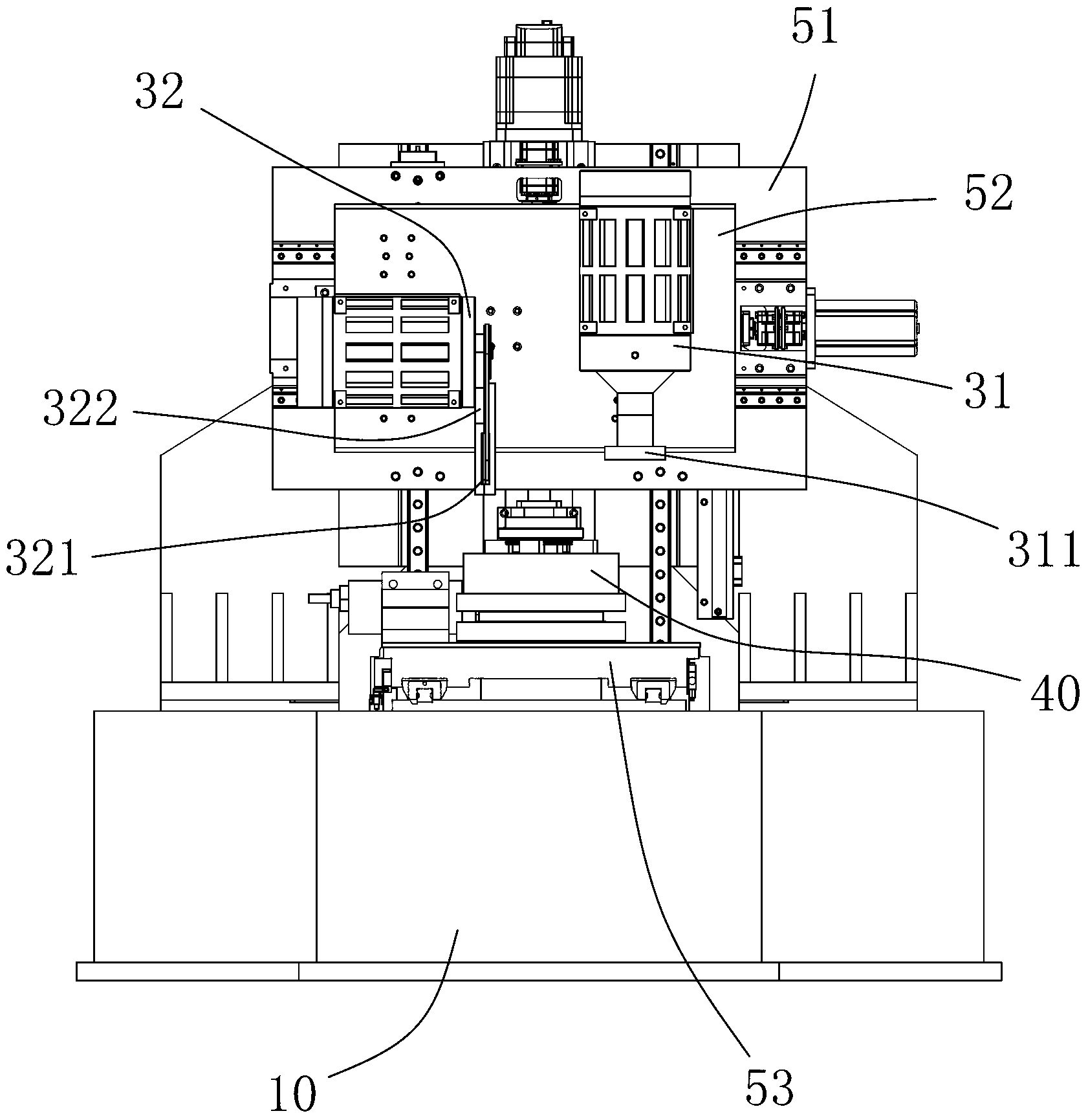

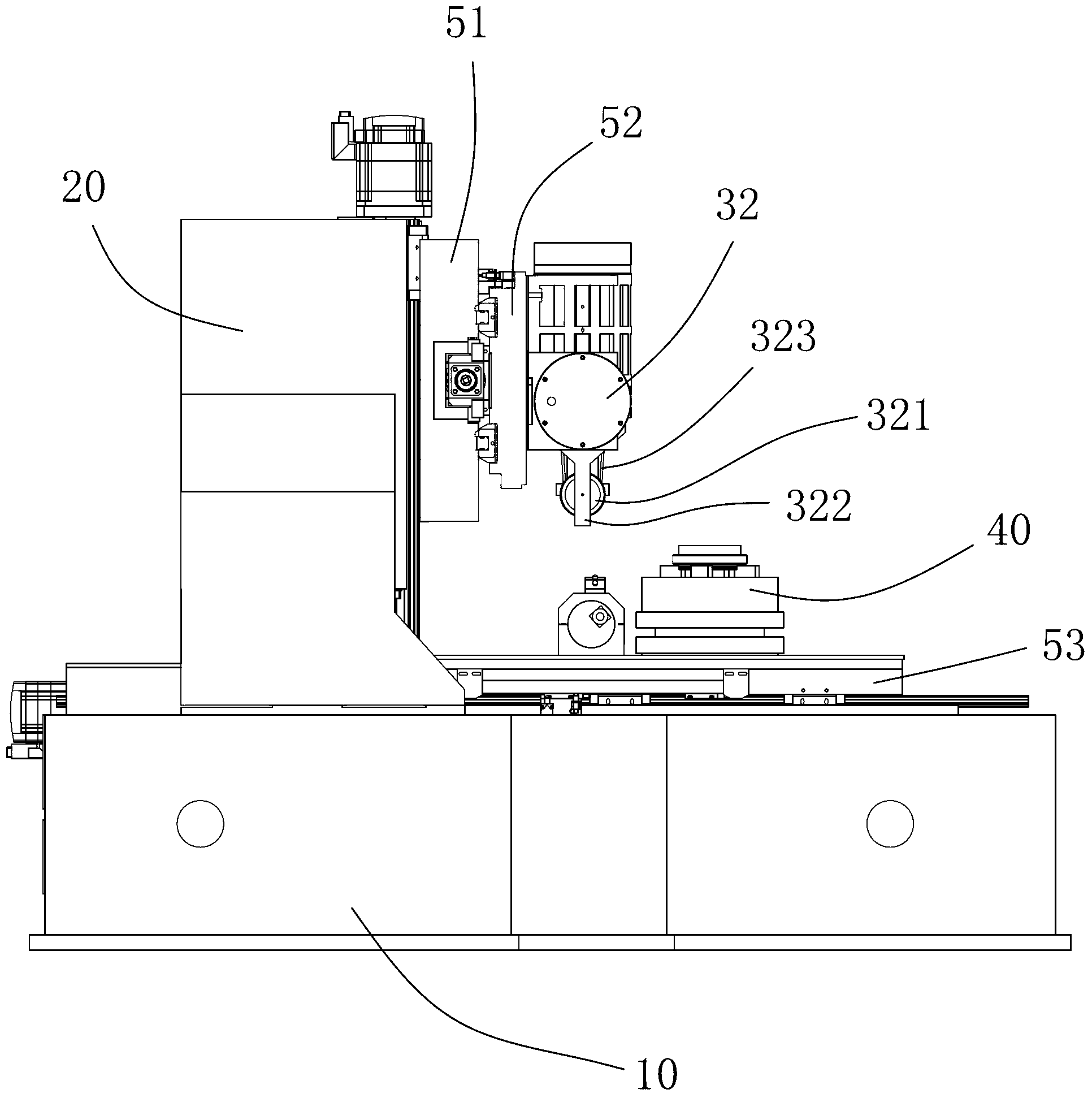

[0018] refer to Figure 1 to Figure 5 , a compound grinding machine tool for grinding pin gear shells according to the present invention, comprising a bed 10, a column 20 arranged on the bed 10, and a first grinding wheel spindle 31 and a second grinding wheel spindle 32 arranged on the column 20, The bed 10 is provided with a workpiece fixture 40, and the bed 10 is provided with a sliding mechanism for relatively moving the workpiece fixture 40 with the first grinding wheel spindle 31 and the second grinding wheel spindle 32. The output end of the first grinding wheel spindle 31 is provided with There is a cylindrical grinding wheel 311 , and a disc-shaped grinding wheel 321 driven by the second grinding wheel main shaft 32 is arranged below the second grinding wheel main shaft 32 .

[0019] In this embodiment, the gear housing 70 of the workpiece to be ground needs to grind the tooth groove 71, the inner circular end surface 72 and the outer circular end surface 73 on its in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com