Machining technology of cobalt beryllium copper blade

A processing technology, a cobalt-copper technology, is applied to the processing technology field of beryllium-cobalt-copper blades, which can solve the problems of low efficiency, difficulty in narrow grooves with slender structures of the blade body, and difficulty in processing precision requirements, so as to improve processing efficiency and improve processing efficiency. Convenience and guarantee the effect of grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0019] The invention provides a processing technique for a beryllium-cobalt-copper blade, the steps comprising:

[0020] Step S1: milling the front end profile and the rear end profile of the beryllium cobalt copper blade and the edges of the front end profile and the rear end profile;

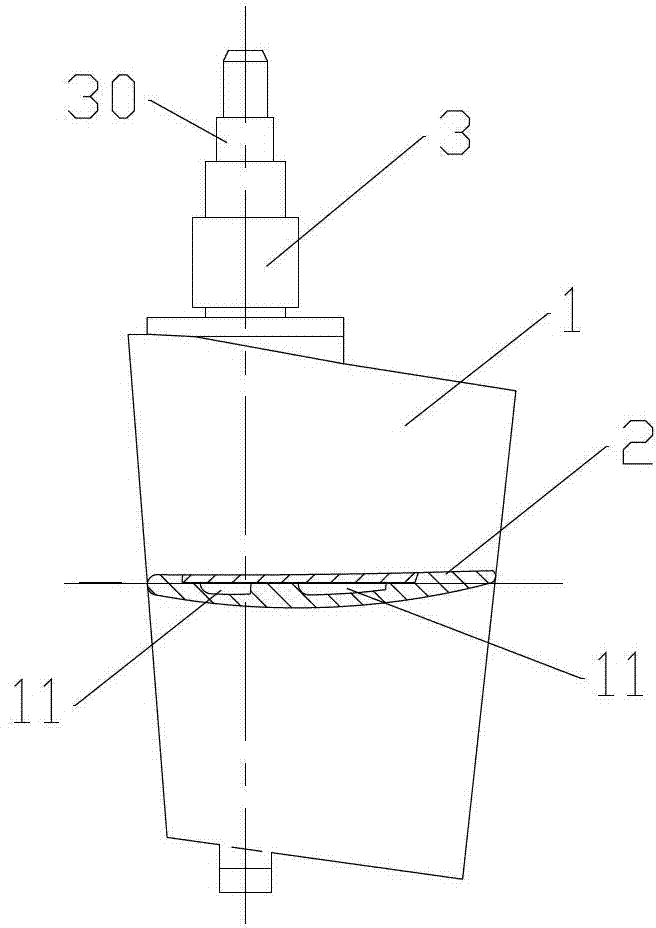

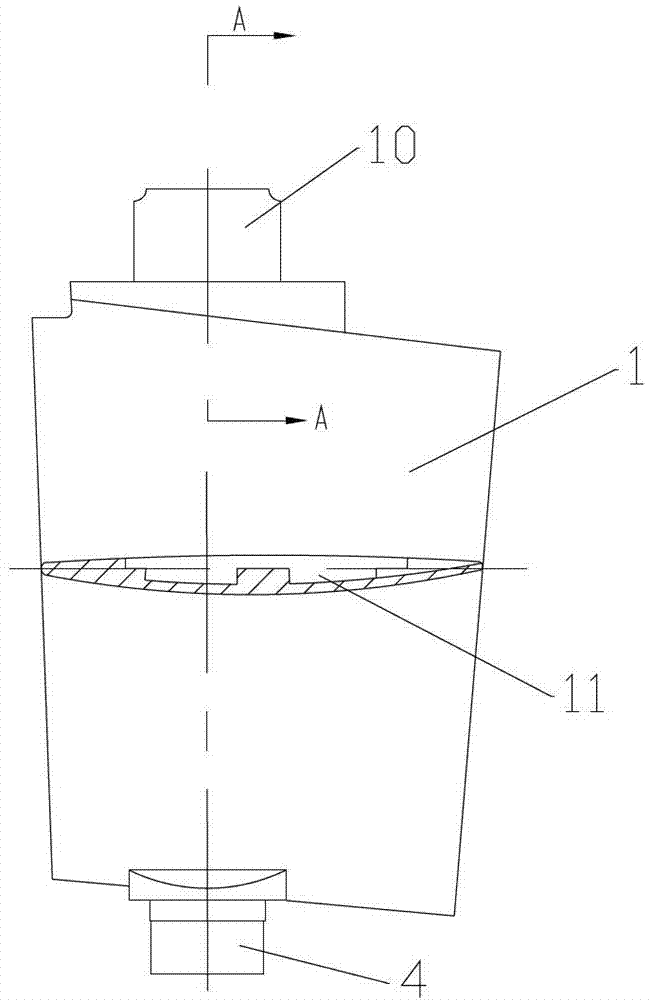

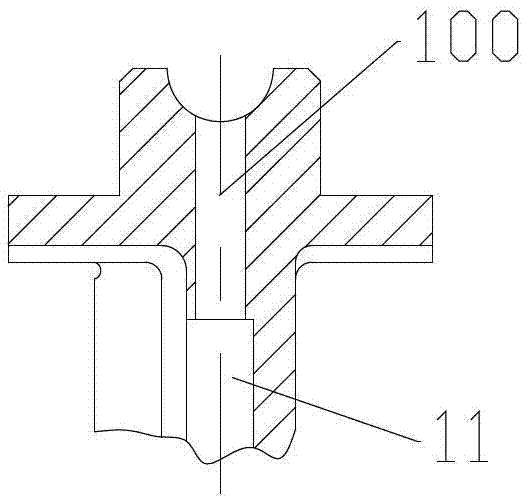

[0021] Among them, the centering block 4 and journal 3 of the beryllium-cobalt-copper blade are clamped on the machine tool for installation and support, and are processed by five-axis linkage high-speed CNC milling. One clamping can mill the front and rear profiles of the blade. And the edge of the front-end profile and the rear-end profile, avoiding the machining error caused by repeated clamping. At the same time, the five-axis high-speed CNC milling can reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com