Three-level centrifugal corn grinder preventing feed from being bridged and grinding method

A pulverizer and secondary pulverization technology, applied in grain processing and other directions, can solve the problems of low pulverization efficiency, excessive power consumption, incomplete corn pulverization, etc., and achieve the effect of improving pulverizing efficiency, reducing pulverizing time, and completely pulverizing and grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment, further illustrate the present invention.

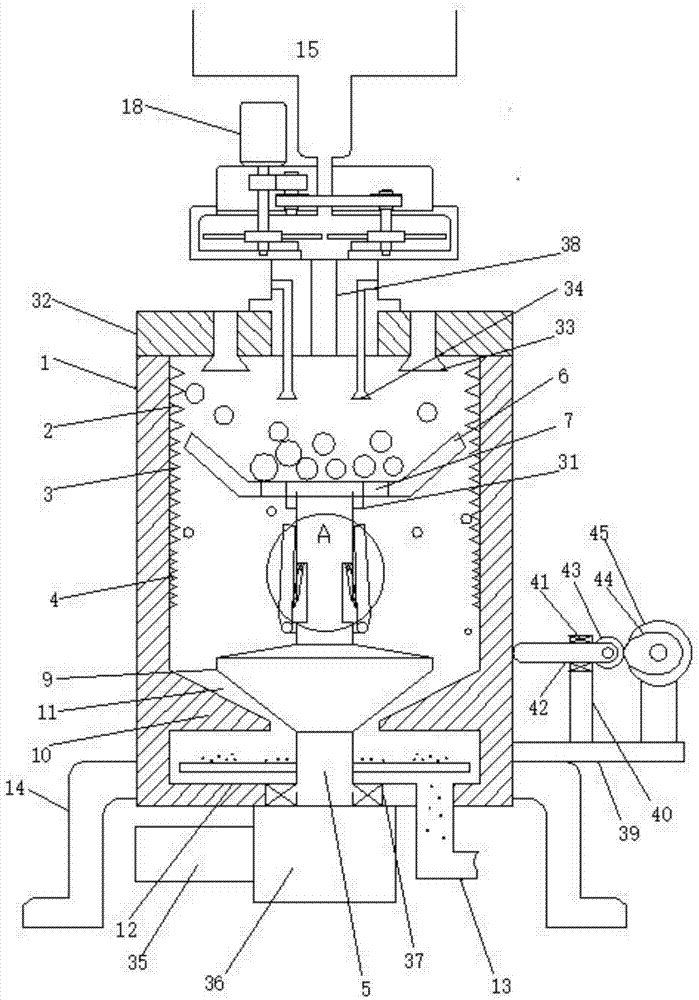

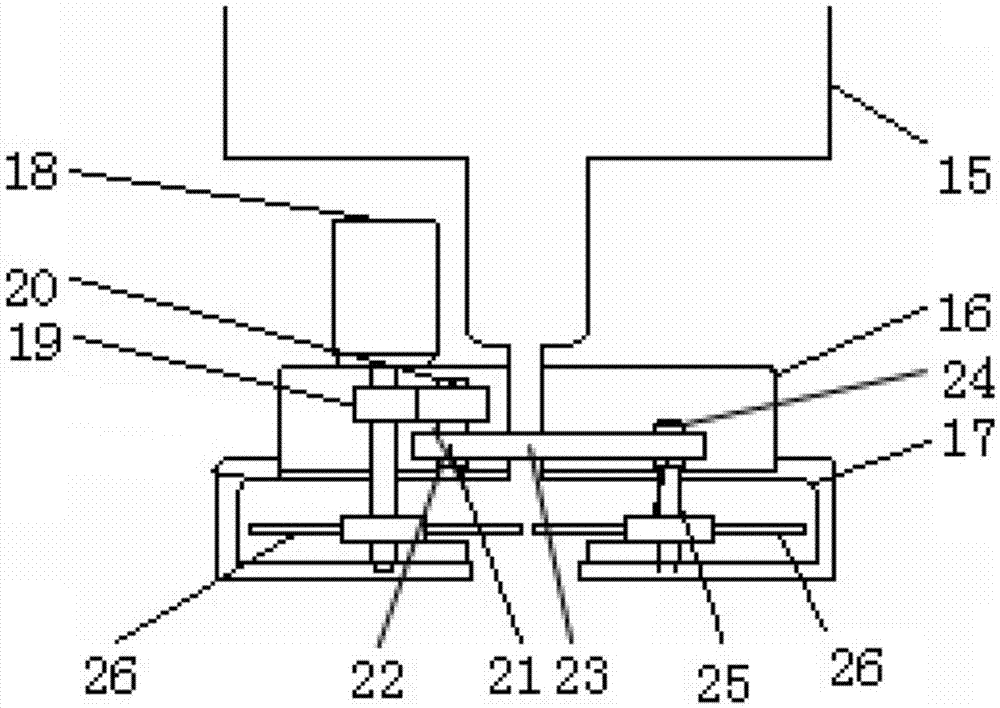

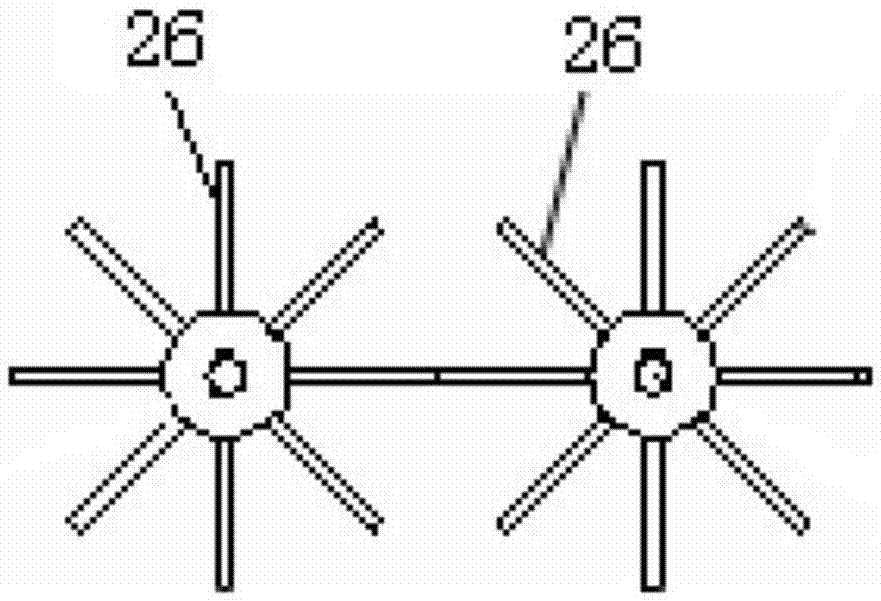

[0026] see Figure 1-Figure 5 , the present invention includes a feeding mechanism, the feeding mechanism communicates with the crushing barrel 1 through a blanking channel 38, and the inner wall of the crushing barrel 1 is sequentially provided with a primary crushing tooth 2, a secondary crushing tooth 3 and a third crushing tooth from top to bottom. stage crushing teeth 4, the crushing barrel 1 is provided with a main shaft 5, the top of the main shaft 5 is provided with a primary rotating pallet 6, and the primary rotating pallet 6 is provided with a primary powder falling port 7, and the primary shaft The middle part of the cylinder 5 is provided with a cylinder installation groove 8, and a secondary crushing mechanism is arranged in the cylinder installation groove 8, and an upper cone mill 9 is arranged on the lower side of the main shaft 5, and the side wall of the crushing bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com