Benzene-free environment-friendly extruding-compositing ink

An environmental protection and ink technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of printing speed adaptability and protection that cannot meet market demand, consumer demand and national policy requirements, human poisonous and harmful, etc., to achieve stability Adhesion and composite fastness, good ink transferability, high adhesion strength effect

Inactive Publication Date: 2010-05-05

LUOYANG TIANXIA INDAL

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But these kinds of products all have deficiencies: the main solvents of benzene-soluble composite inks are toluene and methyl ethyl ketone, and the resin materials are chlorinated polypropylene products. Toxic and harmful to the human body, does not meet people's consumption needs and national policy requirements

However, due to the limitation of the solvent, the printing speed is slow (up to 140 m / min) and can only be used for dry composite printing, and the cost of use is significantly higher than that of benzene-soluble composite inks.

Water-based inks not only fail to meet the market demand in terms of printing speed, adaptability to equipment, and food protection of packaging, but also cost more than alcohol-soluble composite inks, so they cannot be used in the market

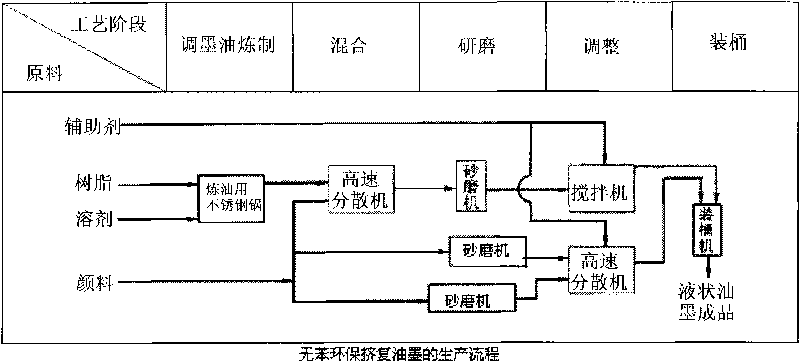

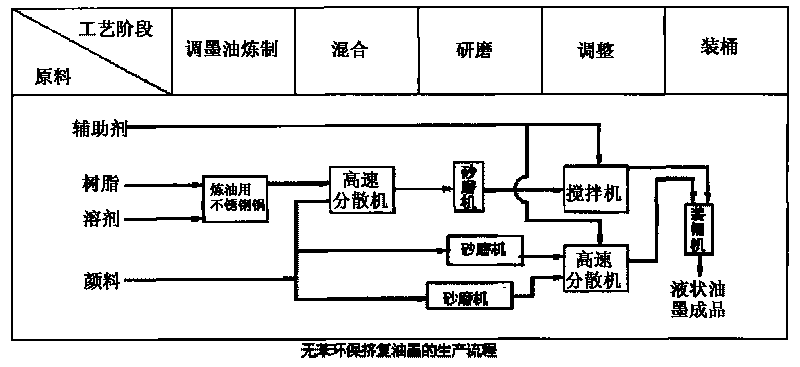

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0027] Example 3 Unit: %

[0028] raw material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of new material environment protection and discloses a benzene-free environment-friendly extruding-compositing ink which comprises the following main raw materials in mass percentage: 5-25% of SBS resin, 5-25% of modified EVA resin, 1-2% of HR-type dispersant, 50-75% of methyl-carbonate and 5-8% of pigment. The benzene-free environment-friendly extruding-compositing ink proposed by the invention has the characteristics of low viscosity, good leveling property, large solid content, bright color, high color concentration, excellent stipple reproducibility, and application in layering sammeld ruck; the ink membrane has high peeling strength and extruding-compositing performance, wherein the peeling strength can reach 5N / 15mm-10N / 15mm, and the extruding-compositing strength is over 0.9N.

Description

technical field [0001] The invention belongs to the technical field of new material environmental protection, and mainly discloses a benzene-free environmental protection extrusion ink. Background technique [0002] In recent years, while paying attention to the aesthetics of the outer packaging of edible products, people have higher requirements for its green, environmental protection, hygiene and safety performance. Especially after the Sanlu milk powder melamine incident caused a global sensation in 2008, the non-toxic and non-toxic Harm has become the focus of consumers, food manufacturers and related industries. For the food industry, the state has also successively introduced the QS compulsory certification system, the "Food Safety Law", and GB / T10004-2008. These systems, laws, and standards have put forward mandatory requirements for the hygienic performance of the food industry. The annual demand for this product in the domestic market is over 200,000 tons. Its adva...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D11/10C09D11/106

Inventor 魏希朝

Owner LUOYANG TIANXIA INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com