Biomass straw sludge fuel and preparation method thereof

A biomass straw and sludge technology, which is applied in the directions of biofuel, waste fuel, fuel, etc., can solve the problems of polluting the atmosphere and high heat consumption, and achieve the effect of increasing calorific value, high fuel calorific value and good flammability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

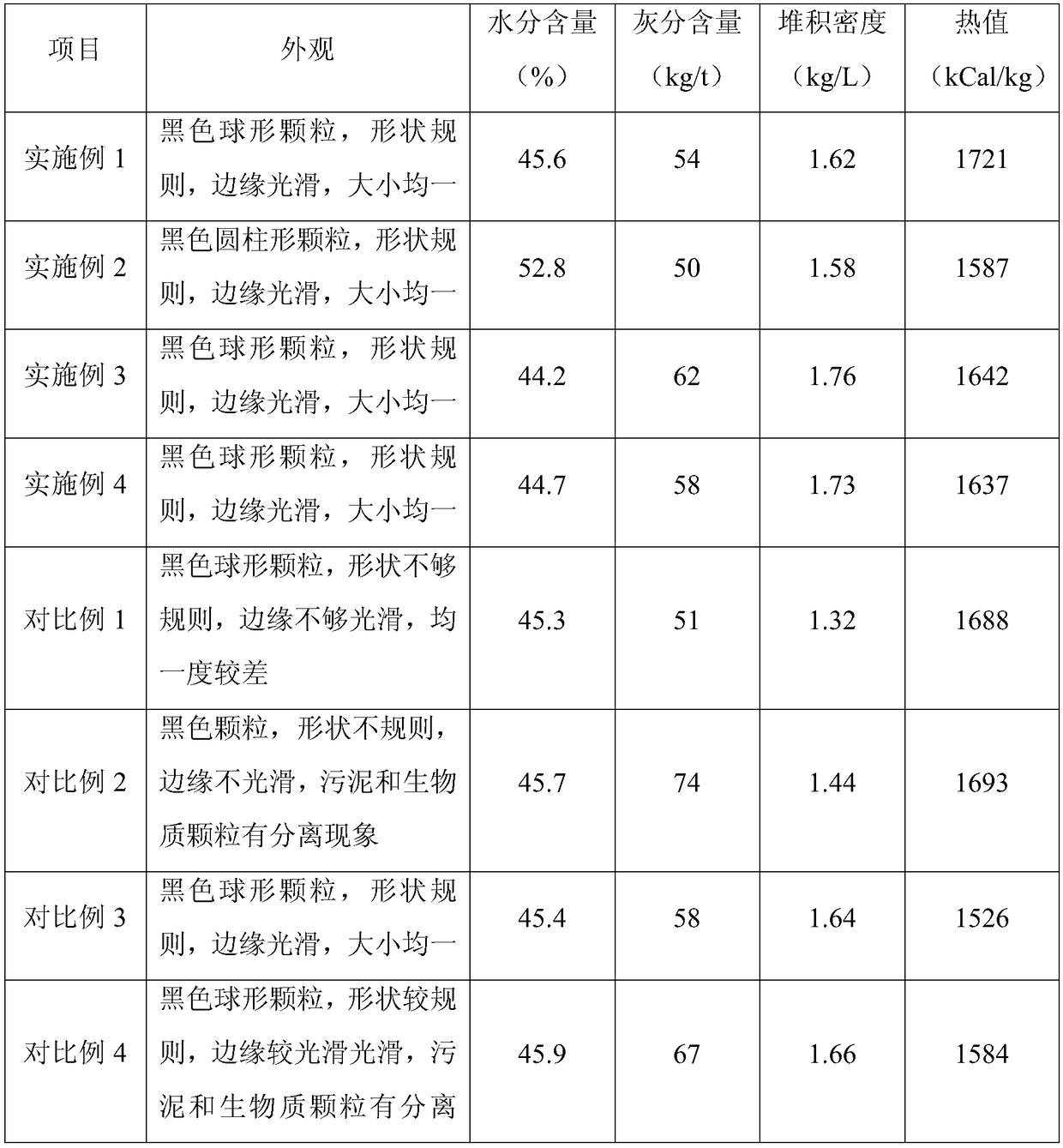

Examples

Embodiment 1

[0032] A kind of biomass straw sludge fuel, which is composed of the following raw materials in parts by weight: 100 parts of municipal sludge with a water content of 60% (organic matter content 450g / Kg), 100 parts of corn straw particles, 1.5 parts of hydroxypropyl methylcellulose share.

[0033] The preparation method is:

[0034] S1: Feed the corn stalks into the crusher and crush them into particles with a particle size of 1mm;

[0035] S2: Send the sludge, corn stalk particles, and hydroxypropyl methylcellulose into the mixing tank in proportion through the quantitative feeder, and stir and mix at room temperature for 20 minutes until the mixture is uniform;

[0036] S3: Send the uniformly mixed materials into the sludge forming machine, which is equipped with a spherical mold with a diameter of 3 cm, and the extrusion pressure is 0.2 mpa; after extrusion, the biomass straw sludge fuel with a particle size of 3 cm is obtained.

Embodiment 2

[0038] A biomass straw sludge fuel, consisting of the following raw materials in parts by weight: 100 parts of municipal sludge with a water content of 70% (organic matter content 420g / Kg), 120 parts of wheat straw particles, 3.5 parts of hydroxypropyl methylcellulose share.

[0039] The preparation method is:

[0040] S1: sending the wheat straw into the crusher, crushing it into particles with a particle size of 1mm;

[0041] S2: Send the sludge, wheat straw particles, and hydroxypropyl methylcellulose into the mixing tank in proportion through the quantitative feeder, and stir and mix at room temperature for 15 minutes until the mixture is uniform;

[0042] S3: Send the uniformly mixed materials into the sludge forming machine. A cylindrical mold with a length of 4cm and a diameter of 0.8cm is installed in the forming machine, and the extrusion pressure is 0.2mpa; after extrusion, the cylindrical biomass straw sludge is obtained. mud fuel.

Embodiment 3

[0044]A biomass straw sludge fuel, consisting of the following raw materials in parts by weight: 100 parts of tannery sludge with a water content of 60% (organic matter content 380g / Kg), 80 parts of soybean straw particles, hydroxypropyl methylcellulose 1 serving.

[0045] The preparation method is:

[0046] S1: Send the soybean stalks into the crusher, and crush them into particles with a particle size of 1mm;

[0047] S2: Send the sludge, soybean straw particles, and hydroxypropyl methylcellulose into the mixing tank in proportion through the quantitative feeder, and stir and mix at room temperature for 30 minutes until the mixture is uniform;

[0048] S3: Send the uniformly mixed materials into the sludge molding machine, which is equipped with a spherical mold with a diameter of 3.5cm, and the extrusion pressure is 0.2mpa; after extrusion molding, the biomass straw sludge with a particle size of 3.5cm is obtained fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com