Springing type garbage extruder

An extrusion machine and waste technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as affecting the efficiency of waste treatment, littering, and polluting the environment, so as to improve the extrusion molding effect, save the amount of use, and improve the recycling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

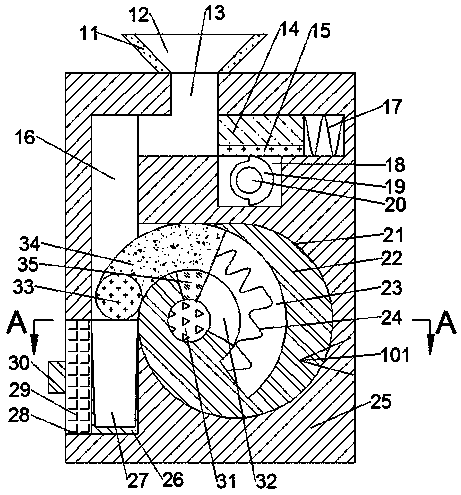

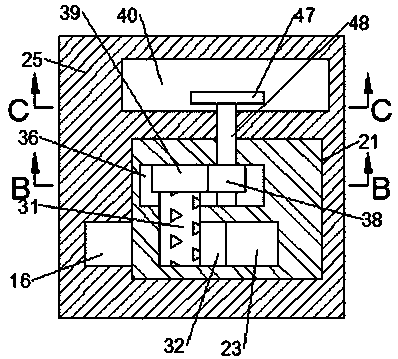

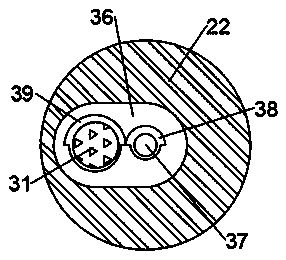

[0015] Combine below Figure 1-4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] refer to Figure 1-4 , according to an embodiment of the present invention, a spring-type garbage extruder includes a body 25, an extrusion chamber 16 is opened in the body 25, and a collection cylinder 26 is placed on the bottom wall of the extrusion chamber 16, so that The collection cylinder 26 is provided with a collection cavity 27 with an opening upwards and can be used to store the squeezed garbage, and the body 25 is provided with an extrusion control mechanism 102 that can squeeze and transport the garbage and provide power to the moving parts in the device. The extrusion control mechanism 102 includes a motor 42, an extrusion block 14 and a disc 22 for conveying and sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com