Lanthanum-containing 6063 aluminum alloy and preparation method

A technology of aluminum alloy and aluminum alloy melt, applied in the field of alloys, can solve the problems of difficulty in mechanical properties such as tensile strength and elongation, and it is difficult to determine the optimal combination of 6063 aluminum alloy with the improvement direction of 6063 aluminum alloy, so as to improve extrusion Processability and effects of tensile strength and elongation, enhanced tissue toughness, high tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method for the lanthanum-containing 6063 aluminum alloy described in the above technical solution, comprising the following steps:

[0034] (1) Provide primary aluminum alloy melt;

[0035] (2) Add Al-Ti-C-La master alloy to the primary aluminum alloy melt in the step (1), carry out metamorphic reaction, obtain metamorphic alloy material liquid, then carry out casting and homogenization treatment successively, obtain containing Lanthanum 6063 aluminum alloy;

[0036] The temperature of the modification reaction is 720-740° C., and the time is 5-10 minutes.

[0037]The invention provides a primary aluminum alloy melt; preferably, a raw material alloy containing silicon, magnesium and aluminum is melted to obtain an original aluminum alloy melt. In the present invention, the melting temperature is preferably 740-780°C, more preferably 740-770°C, even more preferably 740-760°C. The present invention has no special limita...

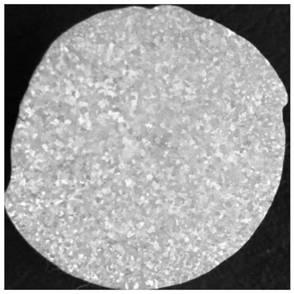

Embodiment 1

[0048] Based on 100% mass content, industrial pure aluminum, industrial magnesium ingot, and aluminum-silicon alloy are used as the original charge, according to Si: 0.46%, Mg: 0.52%, Fe: 0.15%, Cu: 0.02%, Mn: 0.03%, Zn : 0.03%, the balance is Al, and put it into the furnace to melt at 740°C, stir for 5 minutes, add 0.5wt.% hexachloroethane after removing slag, carry out refining at 715°C for 8 minutes, and then refine at 715°C Let stand for 5min.

[0049] After standing still, when the furnace temperature drops to 720°C, add 0.2% Al-5Ti-0.62C-1La master alloy of the mass of the primary aluminum alloy melt, and keep it at 730°C for 5 minutes, and filter the alloy liquid Cast into aluminum rods, raise the temperature to 510-520°C at a rate of 15°C / min, and keep the temperature at this temperature for 12 hours to homogenize the aluminum rods to obtain lanthanum-containing 6063 aluminum alloy.

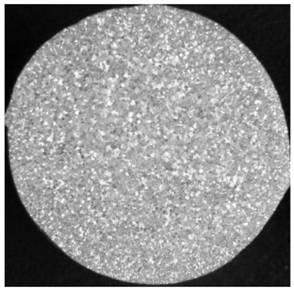

Embodiment 2

[0051] Based on 100% mass content, industrial pure aluminum, industrial magnesium ingot, and aluminum-silicon alloy are used as the original charge, according to Si: 0.5%, Mg: 0.54%, Fe: 0.17%, Cu: 0.042%, Mn: 0.01%, Zn : 0.02%, the balance is Al, and put it into the furnace to melt at 750°C, stir for 5 minutes, add 0.5wt.% hexachloroethane after slag removal, refine at 715°C for 8 minutes, and then refine at 715°C Let stand for 5min.

[0052] After standing still, when the furnace temperature drops to 720°C, add 0.5% Al-5Ti-0.62C-1La master alloy of the mass of the primary aluminum alloy melt, and keep it at 730°C for 5 minutes, and filter the alloy liquid Cast into an aluminum rod, raise the temperature to 510-520°C at a rate of 15°C / min, and keep it at this temperature for 12 hours to homogenize the aluminum rod to obtain lanthanum-containing 6063 aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com