Preparation method of nickel-coated graphite powder for electroconductive rubber of electromagnetic shielding material

A technology of electromagnetic shielding materials and conductive rubber, which is applied in the field of materials, can solve the problems of unqualified conductive rubber products, and achieve the effect of excellent extrusion performance and excellent shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

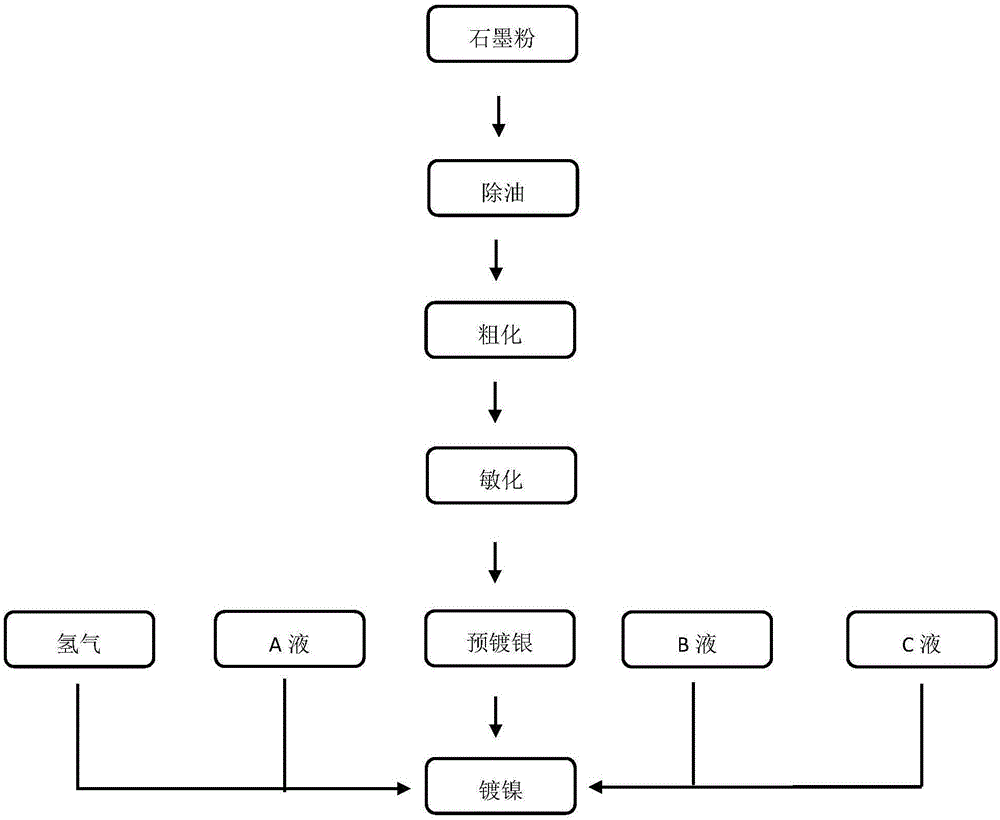

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, spherical artificial graphite coarse powder of 40-160 um is selected, and the preparation method of nickel-coated graphite powder with silver plating of 3 wt % and nickel plating of 60 wt % is as follows.

[0066] (1) Take 50g of graphite powder, soak it in 100ml NaOH solution of 42% concentration for 15min at room temperature, and wash it with deionized water until neutral.

[0067] (2) Immerse the above powder into 100ml of strong acid etching solution mixture prepared according to the mass percentage, the proportioning method is: concentrated sulfuric acid: concentrated phosphoric acid: water = 2:1:7. The soaking temperature is room temperature, and the soaking time is 45 minutes. After the etching is completed, the graphite powder is cleaned to be neutral for use.

[0068] (3) Soak the above powder in 50ml of SnCl with a concentration of 11g / L 2 Mixed with 50ml of HCl with a concentration of 40ml / L, stirred slowly at room temperature at a speed...

Embodiment 2

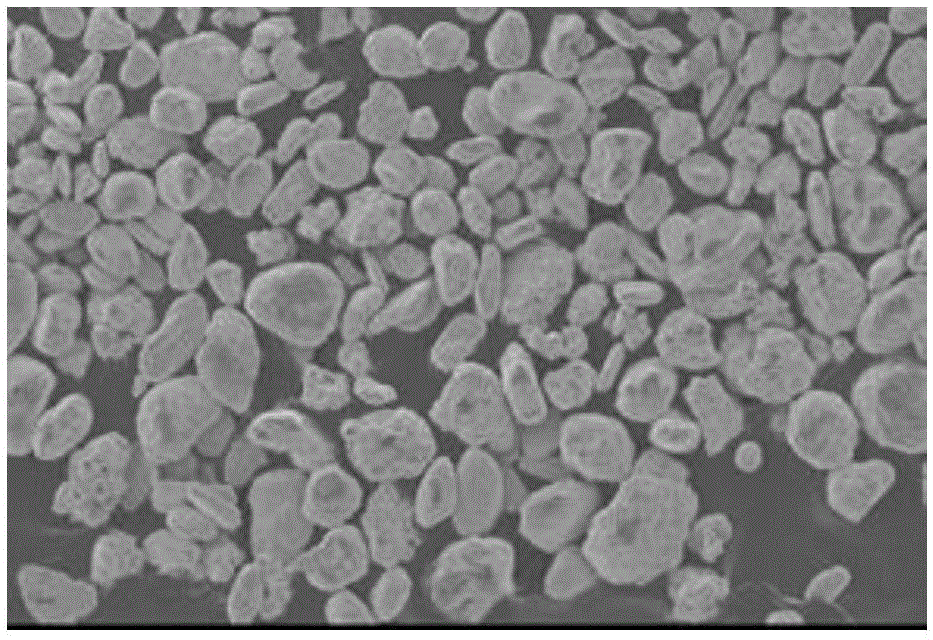

[0078] The present embodiment selects the pillow-shaped artificial graphite coarse powder of 40-160um for use, and the preparation method of the nickel-coated graphite powder of silver-plated 4wt% and nickel-plated 65wt% is:

[0079] Carry out according to the step of embodiment 1 (1), (2), (3), and the silver nitrate concentration in (4) is changed into 32.8g / L, all the other remain unchanged. Change the nickel sulfate of (5) into 431.8g among the embodiment 1, change the citric acid and sodium citrate in the B solution into 28g and 32g, change the thiourea into 2.6mg, all the other remain unchanged. The prepared nickel-coated graphite powder is 148.5g, the thickness of the coating is 6.51um, and the performance indicators of the nickel-coated graphite powder are shown in Table 1 above.

Embodiment 3

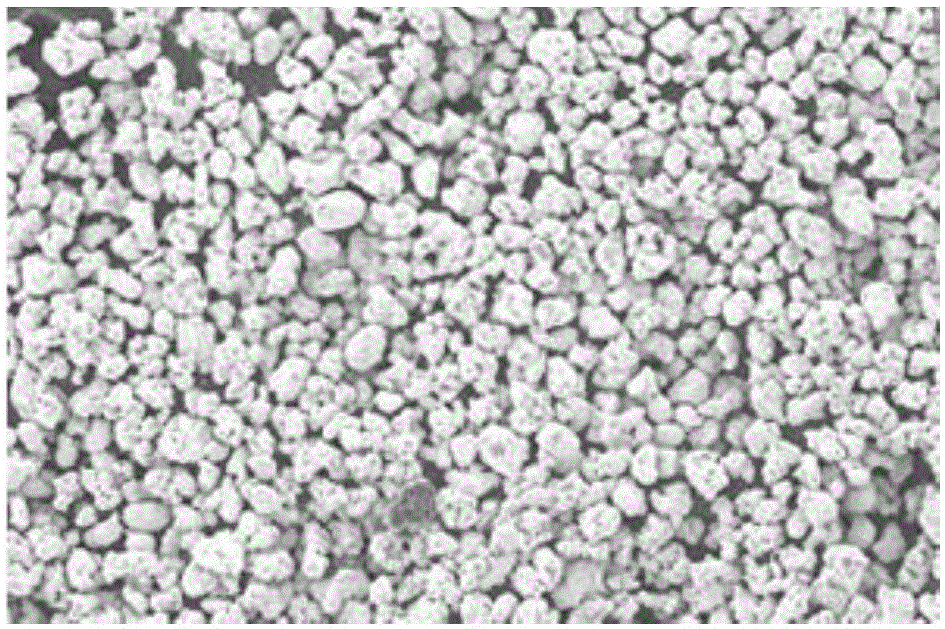

[0081] Present embodiment selects the artificial graphite fine powder of 10-30um for use, the preparation method of the nickel-coated graphite powder of silver plating 8wt% and nickel plating 70wt% is:

[0082] Choose 30g artificial graphite fine powder, and carry out according to the step of embodiment 1 (1), (2), (3). Change the silver nitrate concentration in (4) to 41.1g / L, and all the other remain unchanged. The nickel sulfate of (5) among the embodiment 1 is changed into 339.67g, all the other remain unchanged. The prepared nickel-coated graphite powder is 108.6g, and the thickness of the coating is 5.83um, and its appearance is as follows: image 3 As shown, the performance index of nickel-coated graphite powder is shown in Table 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com