Gray rubber quartz plate and preparation method thereof

A quartz plate and rubber technology, applied in the field of rubber plates, can solve the problems of strong light resistance, wear resistance, acid resistance, poor alkali resistance, acid resistance, alkali resistance, and wear resistance, etc. Save time and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

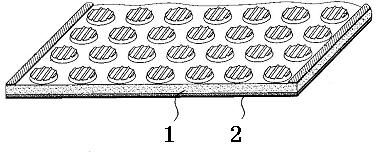

Image

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned gray rubber quartz plate, the method comprises the following steps:

[0063] The first step, ingredients

[0064] Weigh the raw materials for preparing the plate body according to the weight ratio of each raw material, and put them into a barrel with a stirring mechanism to stir evenly;

[0065] The second step, mixing

[0066] Put the well-stirred mixture into the mixer for mixing, the mixing temperature is 80℃~120℃, and the mixing time is 24-26min;

[0067] The third step is to make the film

[0068] Use an open mill to make the mixed rubber into a film;

[0069] The fourth step, vulcanization

[0070] Input the film together with the rough surface layer into the vulcanizing machine for vulcanization, the vulcanization temperature is controlled at 145-165 ℃, and the time is controlled at 24-26min to obtain the finished product;

[0071] The fifth step is packaging.

[0072] For producing the rubber quartz plate descr...

Embodiment 11

[0075] The first step, ingredients

[0076] Weigh 95 kg of EPDM rubber, 5 kg of chlorosulfonated polyethylene, 27--kg of quartz powder, 39--kg of white carbon black, zinc oxide and stearin in a weight ratio of 3:1 4 kg of acid mixture, 5.2 kg of accelerator M, accelerator TMTD and accelerator ZDC in a weight ratio of 5:3:3, 1.4 kg of sulfur, 44 kg of paraffin oil, 0.9 kg of carbon black, 0.9 of binder A kg, 445 1 kg of anti-aging agent, 1.9 kg of coumarone resin, and put them into a barrel with a stirring mechanism to stir evenly;

[0077] The second step, mixing

[0078] Put the well-stirred mixture into an internal mixer for internal mixing, the mixing temperature is 80 °C, and the mixing time is 26 min;

[0079] The third step is to make the film

[0080] Use an open mill to make the mixed rubber into a film;

[0081] The fourth step, vulcanization

[0082] Input the film together with the rough surface layer into the vulcanizer for vulcanization, the vulcanization tem...

Embodiment 12

[0085] The first step, ingredients

[0086] Weigh 95 kilograms of EPDM rubber, 5 kilograms of chlorosulfonated polyethylene, 29 kilograms of quartz powder, 41 kilograms of white carbon black, zinc oxide and stearin in a weight ratio of 3:1 Mixture of acids 4.2 kg, 5:3:3 mixture of accelerator M, accelerator TMTD and accelerator ZDC 5.5 kg, sulphur 1.6 kg, paraffin oil 46 kg, carbon black 1.1 kg, binder A 1.1 kg, antioxidant 445 1.1 kg, coumarone resin 2.1 kg, and put them into a barrel with a stirring mechanism to stir evenly;

[0087] The second step, mixing

[0088] Put the well-stirred mixture into the mixer for mixing, the mixing temperature is 120℃, and the mixing time is 24min;

[0089] The third step is to make the film

[0090] Use an open mill to make the mixed rubber into a film;

[0091] The fourth step, vulcanization

[0092] Input the film together with the rough surface layer into the vulcanizing machine for vulcanization, the vulcanization temperature is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com