Preparation method for motor shell aluminum profile, motor shell and motor

A technology for motor casings and aluminum profiles, which is used in metal extrusion control equipment, manufacturing motor generators, casings/covers/supports, etc., can solve the problem of slow extrusion speed, poor extrusion performance and low production efficiency. and other problems, to achieve the effect of fast extrusion molding rate, improved mechanical properties, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

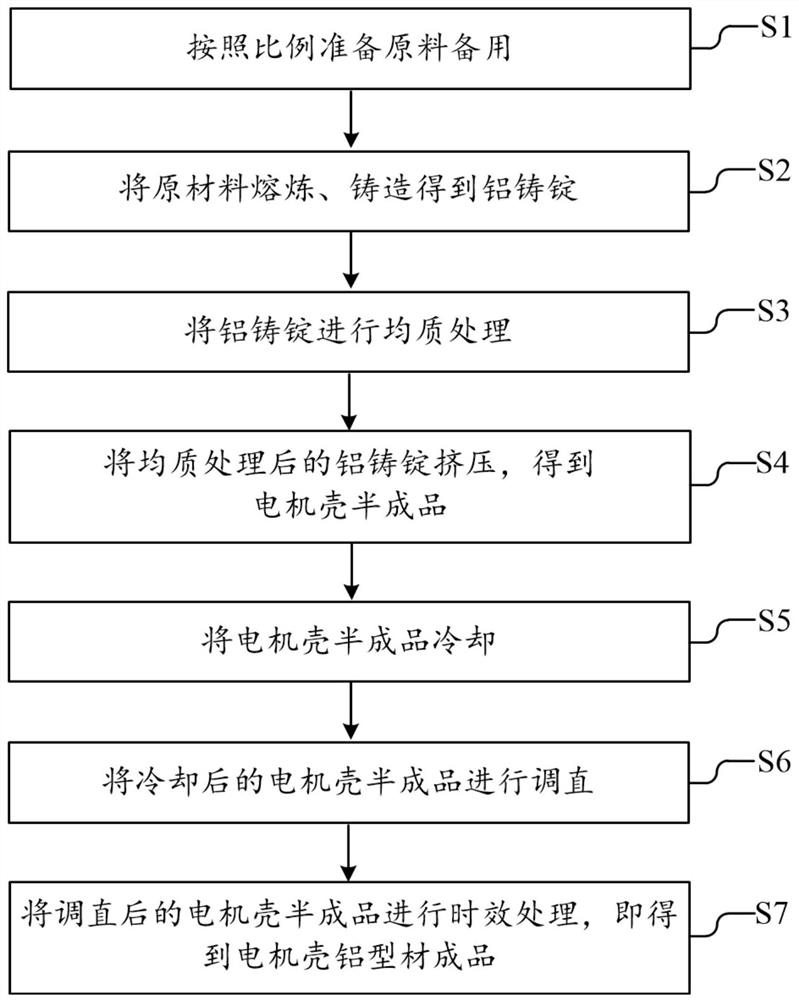

[0045] refer to figure 1 , the invention discloses a method for preparing a motor shell profile, which comprises the following steps:

[0046] S1: Prepare raw materials according to the ratio for use;

[0047] Wherein, the raw material formula in weight percentage is as follows:

[0048] Si 0.6~0.7%, Fe≤0.25%, Cu 0.1~0.2%, Mn≤0.05%, Mg 0.8~0.95%, Cr0.05~0.1%, Zn≤0.1%, Ti≤0.05%, other impurities total≤0.15 %, the balance is aluminum;

[0049] Mg and Si are the main strengthening elements, and Mg and Si can form Mg 2 Si phase, together with the excess silicon phase, strengthens the mechanical properties together. With the Mg in the profile 2 With the increase of Si phase and excess silicon content, the tensile strength, yield strength and quenching sensitivity of the profile increase, but the elongation decreases, and the extrusion performance of the profile becomes worse. For this reason, control Si to be 0.6~0.7%, Mg to be 0.8~0.95%; Preferably, control Si to be 0.6~0.64...

Embodiment 1

[0096] This embodiment provides a method for preparing an aluminum profile of a motor housing, which includes:

[0097] (1) Raw materials are prepared in proportion for subsequent use; wherein, the raw material formula in weight percentage is as follows:

[0098] Si 0.66%, Fe 0.23%, Cu 0.2%, Mn 0.05%, Mg 0.8%, Cr 0.05%, Zn 0.08%, Ti 0.02%, other impurities total 0.1%, and the balance is aluminum;

[0099] (2) Melting and casting raw materials to obtain aluminum ingots;

[0100] (3) Homogenizing the aluminum ingot; wherein, the homogenization temperature is 560° C., and the holding time is 7 hours;

[0101] (4) Extrude the homogenized aluminum ingot to obtain a semi-finished motor casing; wherein, the extrusion temperature is 520°C, and the extrusion speed is 2m / min;

[0102] (5) cooling the semi-finished motor casing;

[0103] (6) Straighten the semi-finished motor casing after cooling; wherein, the straightening amount is 1%;

[0104] (7) Perform aging treatment on the st...

Embodiment 2

[0106] This embodiment provides a method for preparing an aluminum profile of a motor housing, which includes:

[0107] (1) Raw materials are prepared in proportion for subsequent use; wherein, the raw material formula in weight percentage is as follows:

[0108] Si 0.62%, Fe 0.18%, Cu 0.16%, Mn 0.04%, Mg 0.88%, Cr 0.07%, Zn 0.03%, Ti 0.01%, other impurities total 0.12%, the balance is aluminum;

[0109] (2) Melting and casting raw materials to obtain aluminum ingots;

[0110] Specifically, the raw materials are melted at 750-760°C, then refined at 720°C for 20 minutes, and then cast after standing for 20 minutes. The casting temperature is 715°C and the casting speed is 75mm / min;

[0111] (3) homogenizing the aluminum ingot;

[0112] Specifically, the homogenization temperature is 560°C, and the holding time is 7.5 hours; after homogenization, it is first cooled to 195°C with the furnace, and then air-cooled to room temperature;

[0113] (4) Extruding the homogenized alumi...

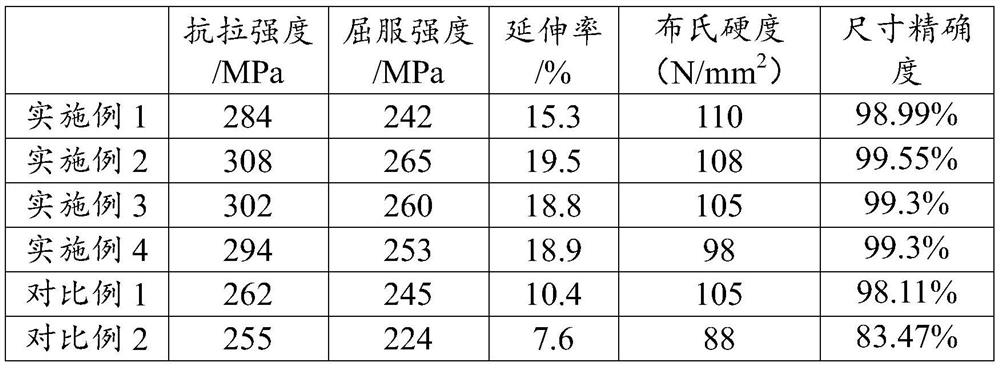

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com