High-abrasion-resistance magnetic engine oil

A technology of anti-wear and engine oil, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of conflicts between energy saving and environmental protection and economic benefits, and unsatisfactory results, and achieve environmental protection and excellent thermal oxidation stability Performance, the effect of meeting economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A kind of strong anti-wear magnetic protective engine oil of the present embodiment is made from the following raw materials in proportion by weight: 60 parts of engine oil base oil, 6 parts of jojoba oil, 2 parts of nano-magnesium borate, 3 parts of isobutylene sulfide, 5 parts of sulfurized calcium alkylphenate, 6 parts of triethanolamine, 4 parts of polyethylene glycol, 1 part of sodium petroleum sulfonate, 3 parts of aluminum stearate, 2 parts of methyl acrylate, 2 parts of pentaerythritol, 0.1 parts of trimethylolpropane 0.2 part, 0.2 part of primary and secondary alkyl zinc salt of sulfur phosphorus.

Embodiment 2

[0013] A kind of strong anti-wear magnetic protective engine oil of the present embodiment is made of the following raw materials in proportion by weight: 80 parts of engine oil base oil, 12 parts of jojoba oil, 5 parts of nano-magnesium borate, 8 parts of isobutylene sulfide, 8 parts of sulfurized calcium alkylphenate, 9 parts of triethanolamine, 6 parts of polyethylene glycol, 3 parts of sodium petroleum sulfonate, 8 parts of aluminum stearate, 4 parts of methyl acrylate, 4 parts of pentaerythritol, 0.5 parts of trimethylolpropane 1.5 parts, primary and secondary alkyl zinc salt of sulfur phosphorus.

Embodiment 3

[0015] A kind of strong anti-wear magnetic protective engine oil of the present embodiment is made from the following raw materials with the optimal ratio by weight: 75 parts of engine oil base oil, 8 parts of jojoba oil, 3 parts of nano-magnesium borate, and 6 parts of isobutylene sulfide 6 parts, 6 parts of sulfurized calcium alkylphenate, 8 parts of triethanolamine, 5 parts of polyethylene glycol, 2 parts of sodium petroleum sulfonate, 5 parts of aluminum stearate, 3 parts of methyl acrylate, 3 parts of pentaerythritol, trimethylol 0.3 parts of propane, 1.2 parts of primary and secondary alkyl zinc salt of sulfur phosphorus.

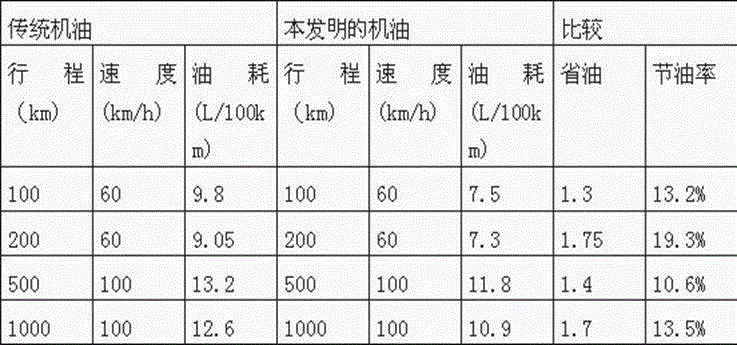

[0016] A kind of strong anti-wear magnetic protective engine oil of the above embodiment is compared to the fuel consumption of a 1.8T car:

[0017]

[0018] A kind of strong anti-wear magnetic protective machine oil of the above embodiment has added borate substances, has good extreme pressure, anti-wear, and friction-reducing properties, and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com