Stainless steel tube drawing oil

A stainless steel pipe and drawing oil technology, applied in the field of lubricating oil, can solve the problems of no uniform quality standard, small production scale, dispersion, etc., and achieve the effect of eliminating the anti-rust treatment of the workpiece, low friction coefficient, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

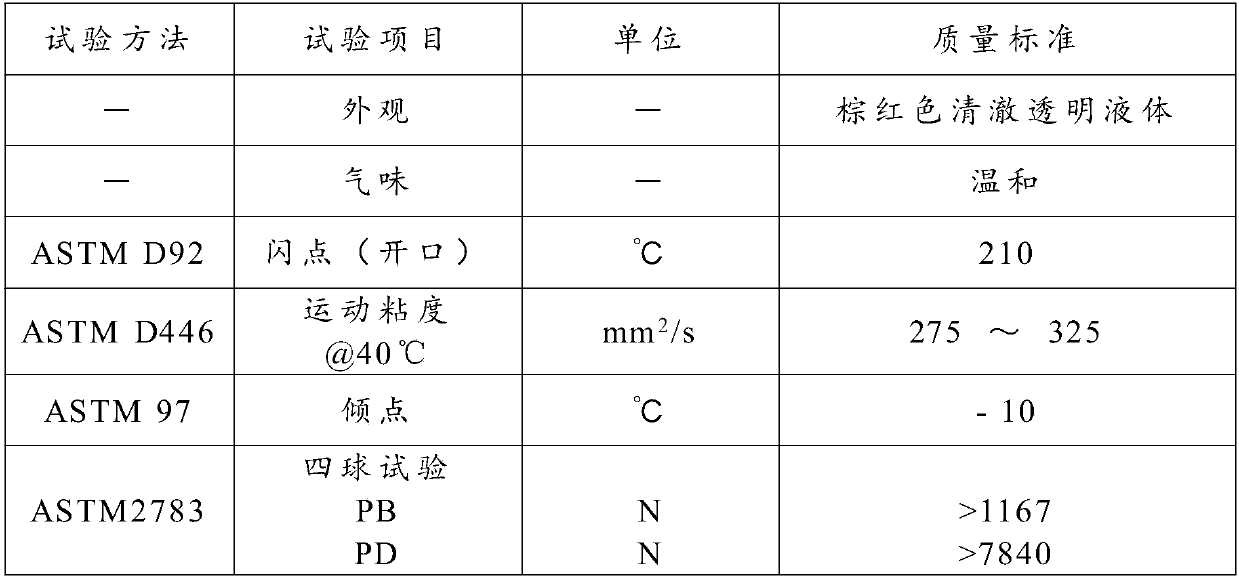

Image

Examples

Embodiment 1

[0027] A stainless steel pipe drawing oil, its components and mass percentages are:

[0028] RC 2526: 0.5%

[0029] SDA 115 Sulfurized fatty acid esters: 3.0%

[0030] RC 2540 sulfurized olefins: 1%

[0031] Medium carbon chain chlorinated fat: 8%

[0032] T202: 1.5%

[0033] Refined Lard: 7%

[0034] T501: 0.3%

[0035] T705: 1.5%

[0036] 500SN paraffinic base oil: 10%

[0037] 150BS base oil: balance.

Embodiment 2

[0039] A stainless steel pipe drawing oil, its components and mass percentages are:

[0040] RC 2526: 3.0%

[0041] SDA 115 Sulfurized fatty acid esters: 1%

[0042] RC 2540 sulfurized olefins: 5%

[0043] Medium-chain chlorinated fat: 3%

[0044] T202: 3.0%

[0045] Refined Lard: 3%

[0046] T501: 1.0%

[0047] T705: 0.5%

[0048] 500SN paraffinic base oil: 20%

[0049] 150BS base oil: balance.

Embodiment 3

[0051] A stainless steel pipe drawing oil, its components and mass percentages are:

[0052] RC 2526: 1.5%

[0053] SDA 115 Sulfurized fatty acid esters: 2%

[0054] RC 2540 sulfurized olefins: 3%

[0055] Medium carbon chain chlorinated fat: 5%

[0056] T202: 2%

[0057] Refined Lard: 5%

[0058] T501: 0.6%

[0059] T705: 1%

[0060] 500SN paraffinic base oil: 15%

[0061] 150BS base oil: balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com