Steel pipe cold drawing oil

A cold-drawn oil and steel pipe technology, used in the petroleum industry, additives, lubricating compositions, etc., can solve the problem of inability to process slender and thin-walled cylinders, and achieve excellent extreme pressure and lubricity, low friction coefficient, extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

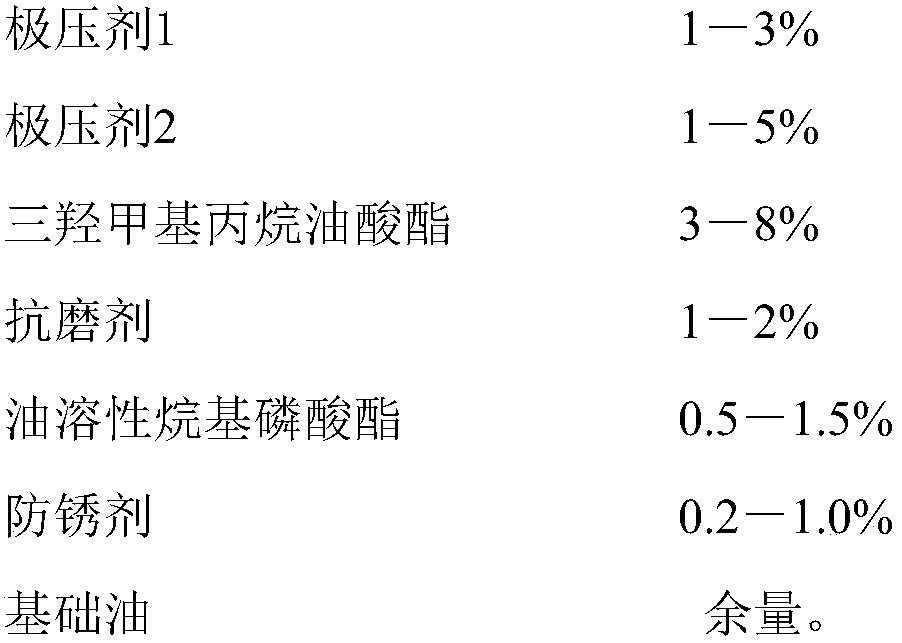

[0022] A kind of steel pipe cold drawing oil, its raw material composition and its weight are respectively:

[0023]

[0024] The preparation method of above-mentioned steel pipe cold drawing oil is:

[0025] Mix the components in proportion, stir and heat to 30-40°C, stir for 30 minutes until the oil is clear and transparent, and let stand for 20 minutes to obtain the product.

Embodiment 2

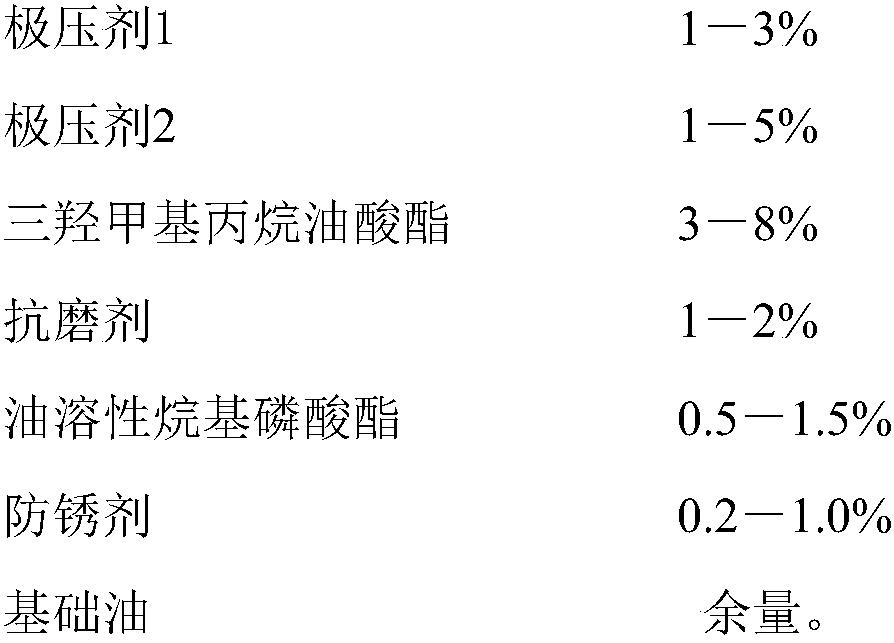

[0027] A kind of steel pipe cold drawing oil, its raw material composition and its weight are respectively:

[0028]

[0029]

[0030] The preparation method of the above steel pipe cold drawing oil is the same as in Example 1.

Embodiment 3

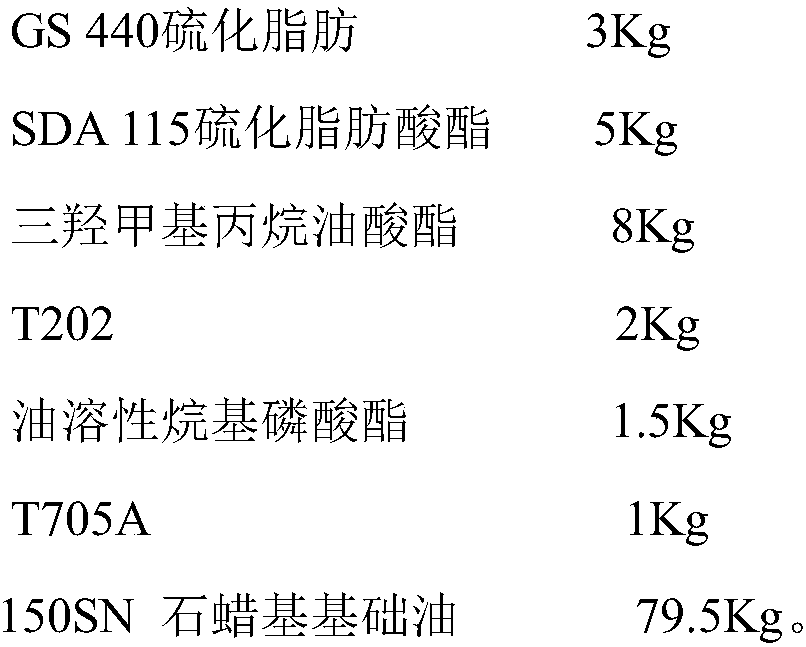

[0032] A kind of steel pipe cold drawing oil, its raw material composition and its weight are respectively:

[0033]

[0034] The preparation method of the above steel pipe cold drawing oil is the same as in Example 1.

[0035] After testing, the steel pipe cold drawing oil index provided by the present invention is as follows:

[0036] experiment method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com