Environment-friendly extreme-pressure anti-wear anti-flame turbine oil composition

An extreme pressure, anti-wear, and environment-friendly technology, used in the field of turbine lubricants, which can solve problems such as danger and achieve good oxidation stability and rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

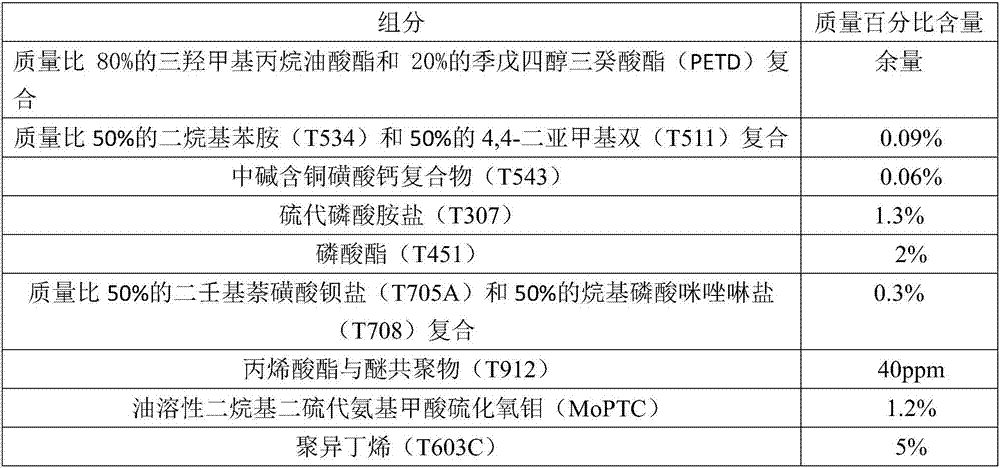

Embodiment 1

[0015] The following components are reconciled according to the percentage content:

[0016]

[0017] The sum of the mass percentages of the above components is 100%.

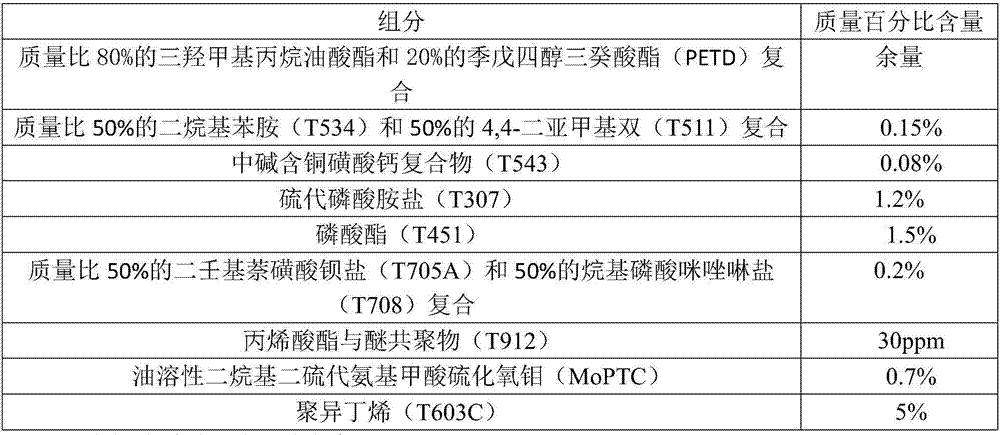

Embodiment 2

[0019] The following components are reconciled according to the percentage content:

[0020]

[0021] The sum of the mass percentages of the above components is 100%.

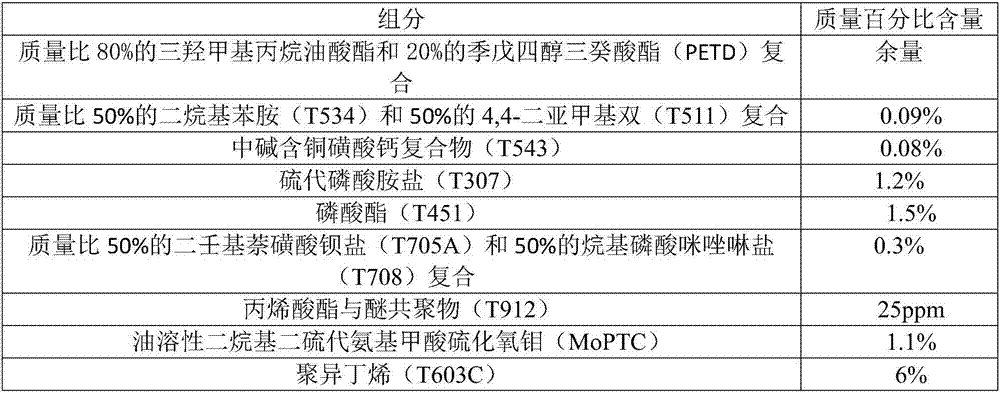

Embodiment 3

[0022] Embodiment 3: the following components are reconciled by percentage content:

[0023]

[0024] The sum of the mass percentages of the above components is 100%.

[0025] Embodiment 1 typical physical and chemical index:

[0026]

[0027] Embodiment 2 typical physical and chemical indicators:

[0028]

[0029] Embodiment 3 typical physical and chemical indicators:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com