Multifunctional lubricant additive for dithioamino acid triazine derivative and preparation method and application of multifunctional lubricant additive

A lubricating oil additive, arginine-based technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve problems such as use restrictions, achieve excellent extreme pressure, mild reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

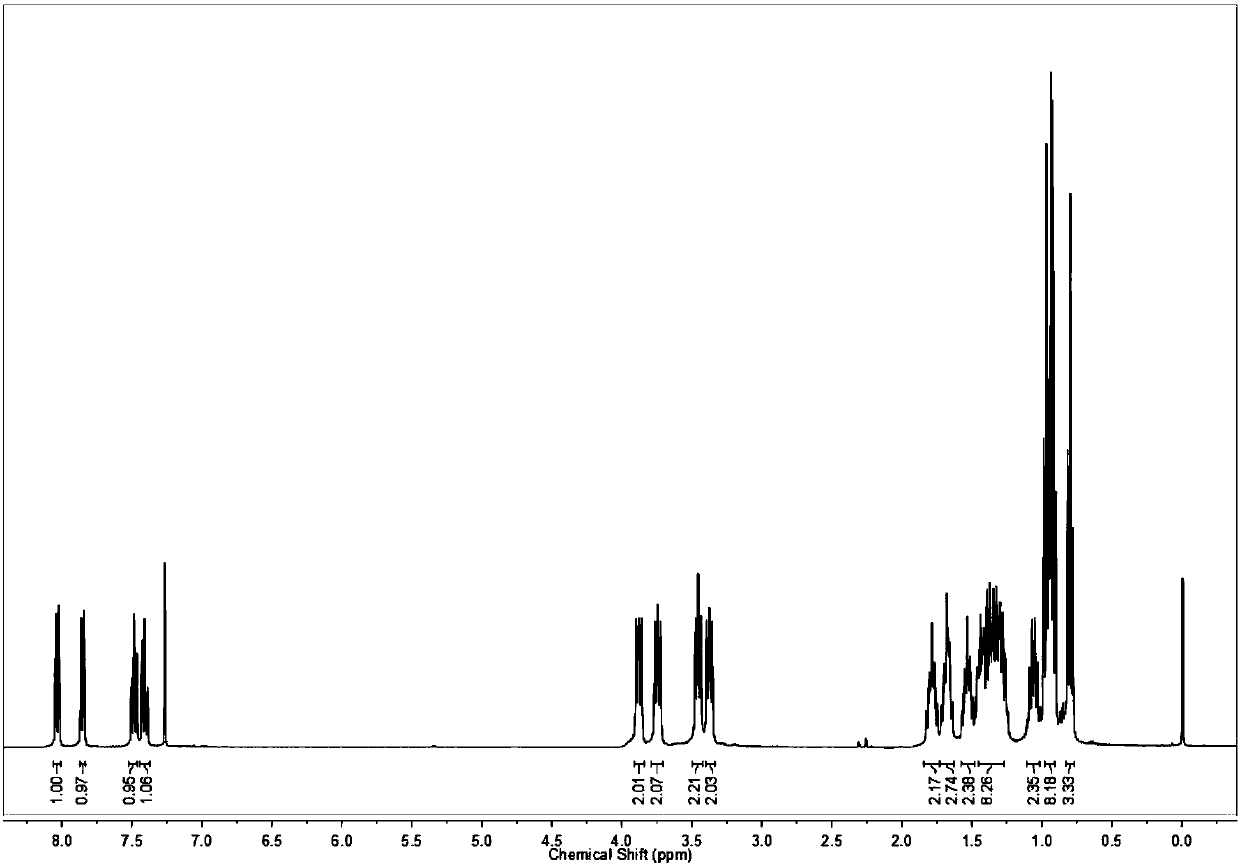

[0036] With 0.05mol (9.25g) cyanuric chloride, 0.06mol (8.30g) K 2 CO 3 and 80 mL of acetone were sequentially added into a 250 mL three-necked flask, and 0.05 mol (6.46 g) of di-n-butylamine was added dropwise under ice cooling, and the reaction was carried out for 2.0 h. After the reaction, pour the reaction solution into a separatory funnel, extract with ether, wash with saturated brine, dry over anhydrous magnesium sulfate, filter, and remove the solvent by rotary evaporation of the filtrate to obtain 2-di-n-butylamino-4,6-di Chloro-1,3,5-s-triazine.

[0037] Dissolve 0.05mol (8.362g) 2-mercaptobenzothiazole and 0.06mol (3.366g) KOH in a mixture of 20mL acetone and 20mL water to prepare a potassium salt solution of 2-mercaptobenzothiazole for later use. Add 0.04mol (11.04g) of 2-di-n-butylamino-4,6-dichloro-1,3,5-s-triazine and 20mL of acetone into a 250mL three-neck flask, raise the temperature to 42°C, and add 2-mercapto The potassium salt solution of benzothiazole wa...

Embodiment 2

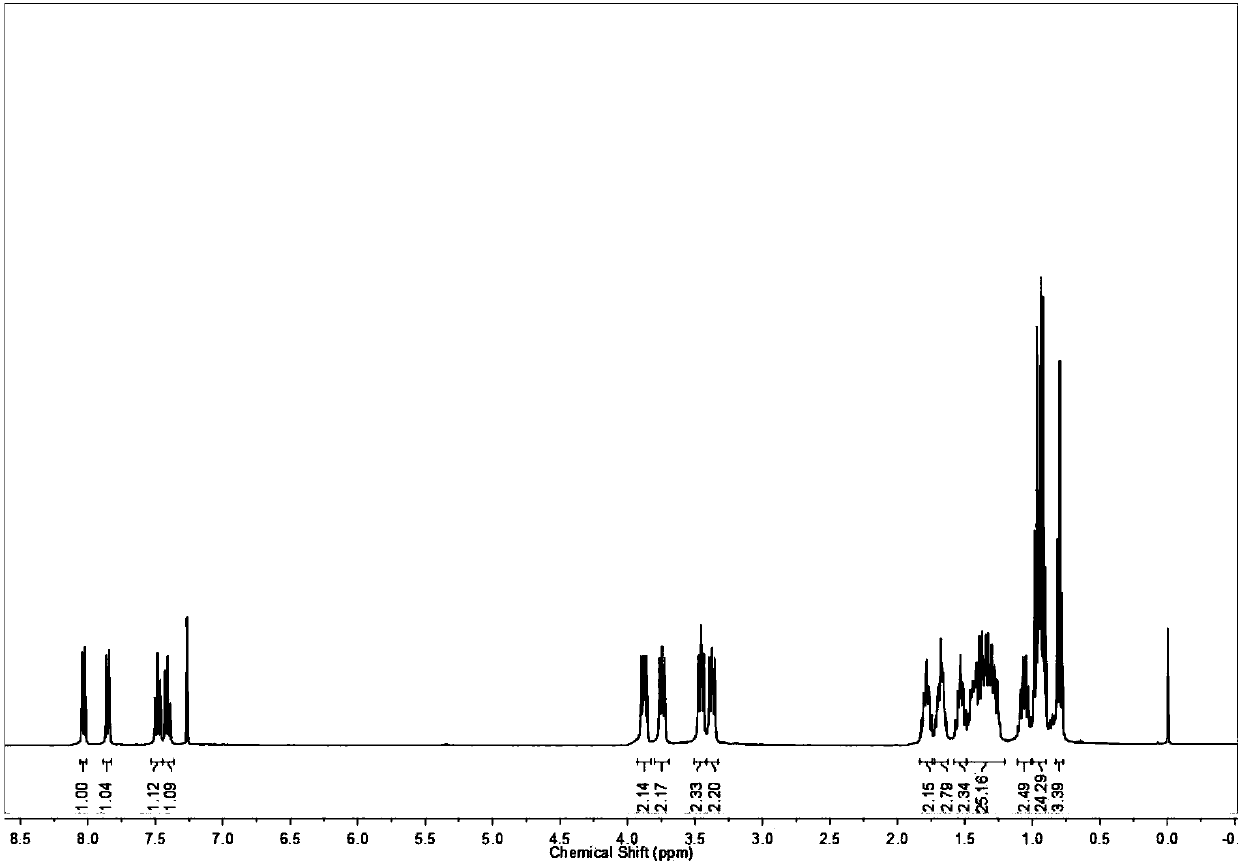

[0040] With 0.05mol (9.25g) cyanuric chloride, 0.06mol (8.30g) K 2 CO 3 and 80 mL of acetone were sequentially added into a 250 mL three-necked flask, and 0.05 mol (12.07 g) of di-n-octylamine was added dropwise under ice cooling, and the reaction was carried out for 2.0 h. After the reaction, pour the reaction solution into a separatory funnel, extract with ether, wash with saturated brine, dry over anhydrous magnesium sulfate, filter, and remove the solvent by rotary evaporation of the filtrate to obtain 2-dioctylamino-4,6-di Chloro-1,3,5-s-triazine.

[0041] Dissolve 0.05mol (8.362g) 2-mercaptobenzothiazole and 0.06mol (3.366g) KOH in a mixture of 20mL acetone and 20mL water to prepare a potassium salt solution of 2-mercaptobenzothiazole for later use. Add 0.04mol (15.53g) of 2-n-octylamino-4,6-dichloro-1,3,5-s-triazine and 20mL of acetone into a 250mL three-neck flask, raise the temperature to 42°C, and add 2-mercapto The potassium salt solution of benzothiazole was rea...

Embodiment 3

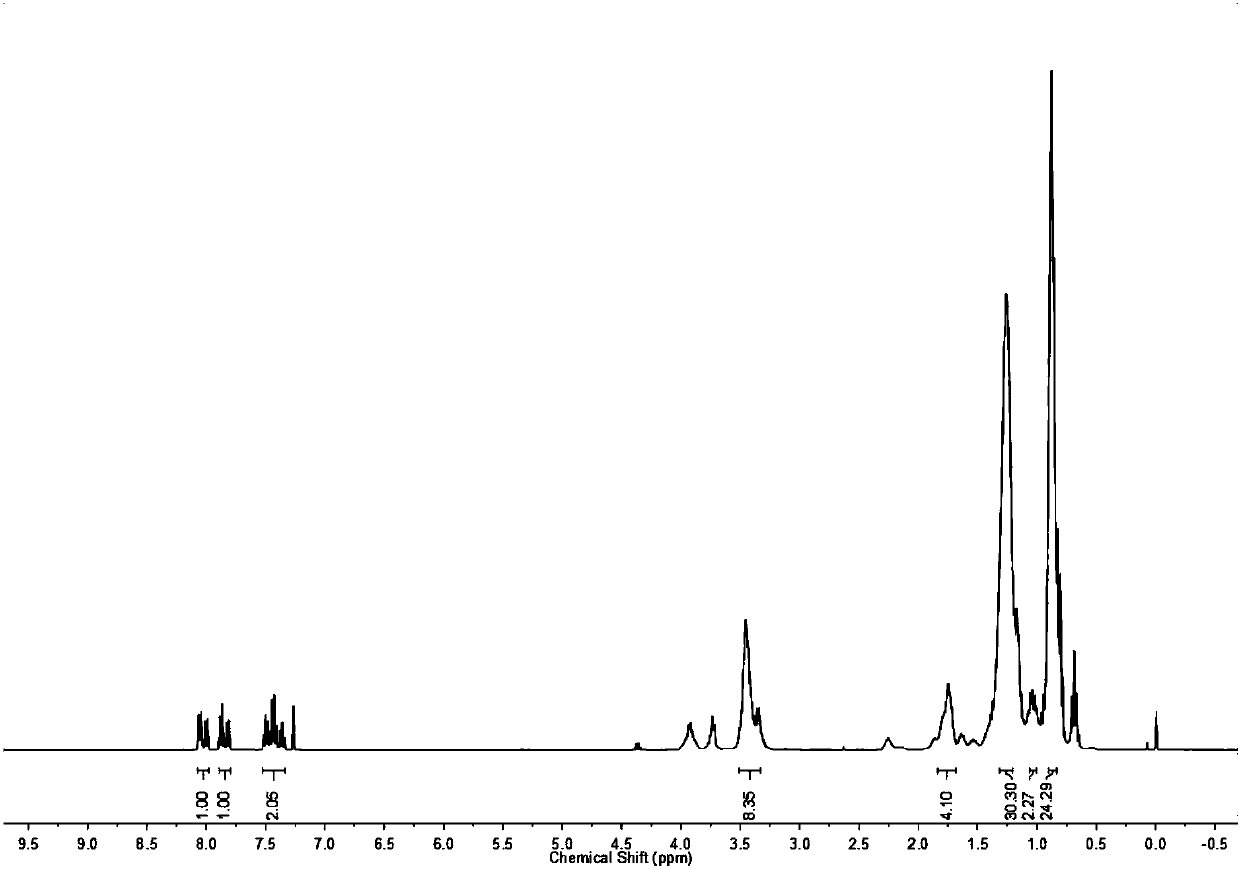

[0044] With 0.05mol (9.25g) cyanuric chloride, 0.06mol (8.30g) K 2 CO 3 and 80 mL of acetone were sequentially added into a 250 mL three-neck flask, and 0.05 mol (12.07 g) of di-isooctylamine was added dropwise under ice cooling, and the reaction was carried out for 2.0 h. After the reaction, the reaction solution was poured into a separatory funnel, extracted with ether, washed with saturated brine, dried over anhydrous magnesium sulfate, filtered, and the filtrate was rotary evaporated to remove the solvent to obtain 2-dioctylamino-4,6-di Chloro-1,3,5-s-triazine.

[0045] Dissolve 0.05mol (8.362g) 2-mercaptobenzothiazole and 0.06mol (3.366g) KOH in a mixture of 20mL acetone and 20mL water to prepare a potassium salt solution of 2-mercaptobenzothiazole for later use. Add 0.04mol (15.53g) of 2-dioctylamino-4,6-dichloro-1,3,5-s-triazine and 20mL of acetone into a 250mL three-neck flask, raise the temperature to 42°C, and add 2-mercapto The potassium salt solution of benzothi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com