Water-based response type multifunctional metal machining liquid and preparation method thereof

A metal cutting fluid and reactive technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of narrow application range of metal cutting fluid, short service life of metal cutting fluid, easy adhesion of metal cutting fluid, etc., and improve machining accuracy and surface finish, wide application range, excellent cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

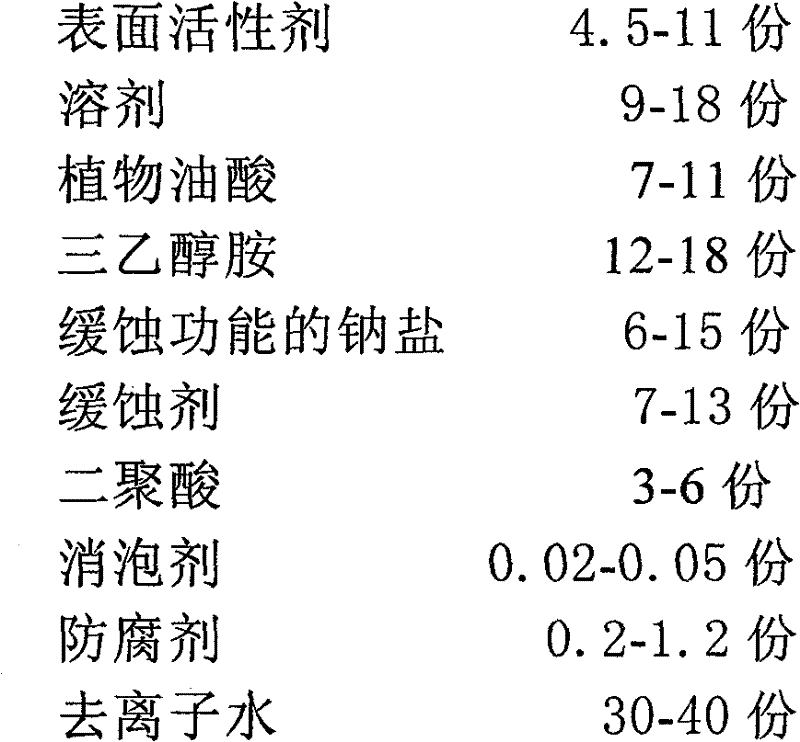

[0046] A water-based reactive multifunctional metal cutting fluid, its composition and weight (kg) are respectively:

[0047] Surfactant 4.5 [of which EL-10 2; OP-10 2; 6501 (Ninal) 0.5];

[0048] Solvent 9 (polyethylene glycol 5; ethylene glycol 2; ethylene glycol butyl ether 2);

[0049] Vegetable oleic acid 7;

[0050] Triethanolamine 12;

[0051] Sodium salt 6 with corrosion inhibition function (including trisodium phosphate 2; sodium molybdate 2; sodium benzoate 2);

[0052] Corrosion inhibitor 7 (including triethyl oleic acid soap 5; sodium petroleum sulfonate 2);

[0053] dimer acid 3;

[0054] Defoamer 903 0.02;

[0055] preservative 1227 0.2;

[0056] Deionized water 30.

[0057] The preparation method of the water-based reactive multifunctional metal cutting fluid, the steps of the preparation method are:

[0058] (1) Add 30 kg of deionized water to the reaction kettle equipped with reflux condenser, stirrer, thermometer and feeding funnel, heat up to 75°C, a...

Embodiment 2

[0065] A water-based reactive multifunctional metal cutting fluid, its composition and weight (kg) are respectively:

[0066] Surfactant 11 [of which EL-10 4; OP-10 4; 6501 (Ninal) 3];

[0067] Solvent 18 (polyethylene glycol 8; ethylene glycol 5; butyl glycol 5);

[0068] Vegetable oleic acid 11;

[0069] Triethanolamine 18;

[0070] Sodium salt 15 with corrosion inhibition function (including trisodium phosphate 5; sodium molybdate 5; sodium benzoate 5);

[0071] Corrosion inhibitor 13 (of which triethyl oleate soap 8; sodium petroleum sulfonate 5);

[0072] dimer acid 6;

[0073] Defoamer 903 0.05;

[0074] Preservatives 1227 1.2;

[0075] Deionized water 40.

[0076] The preparation method of the water-based reactive multifunctional metal cutting fluid, the steps of the preparation method are:

[0077] (1) Add 40 kg of deionized water to the reaction kettle equipped with reflux condenser, stirrer, thermometer and feeding funnel, heat up to 75°C, add 4 kg of EL-10, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com