High-performance environmentally-friendly antifreeze solution for hydraulic supports, and preparation method thereof

A hydraulic support and environment-friendly technology, applied in chemical instruments and methods, materials for heat exchange, petroleum industry, etc., can solve the problems of unsafe production process, low production efficiency, long production time, etc., and achieve shortened production cycle, The effect of lower material costs and simpler production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

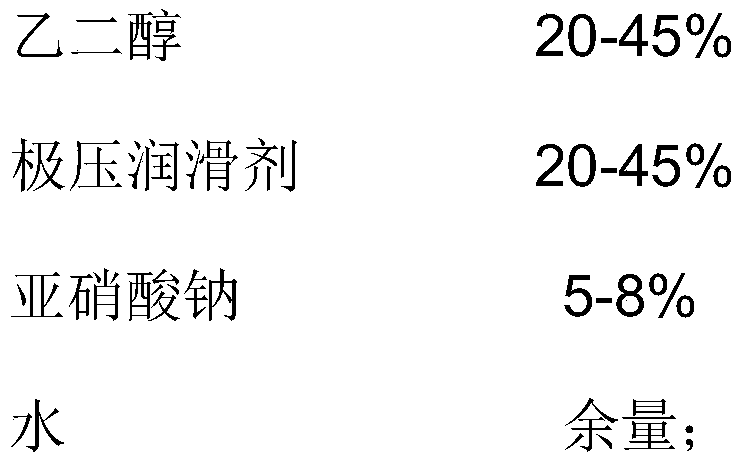

[0028] A kind of high-performance environment-friendly antifreeze liquid for hydraulic supports of the present embodiment is made of the following raw materials by mass percentage:

[0029]

[0030]

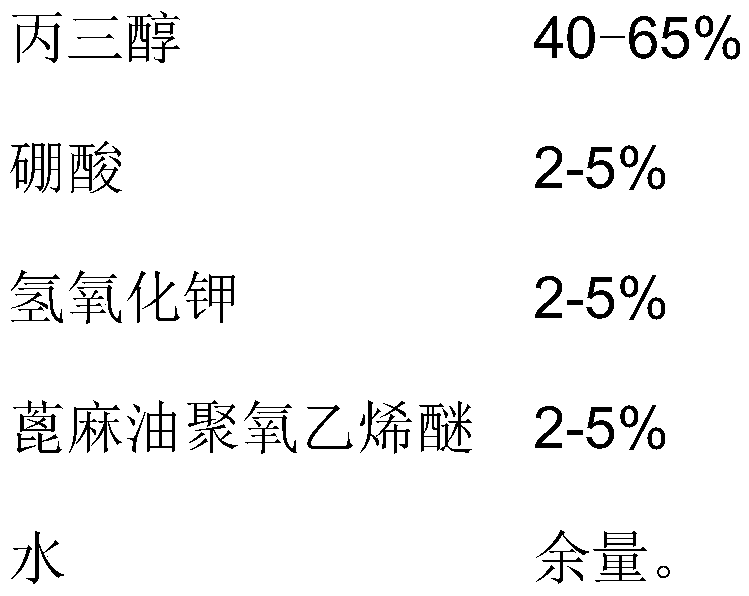

[0031] The extreme pressure lubricant is made of the following raw materials by mass percentage:

[0032]

[0033] The preparation method of the antifreeze of the present embodiment is through the following steps:

[0034] (1) Preparation of extreme pressure lubricant: take glycerol, boric acid, potassium hydroxide, castor oil polyoxyethylene ether, water according to the required mass parts, and put the above-mentioned substances into the mixing tank at a temperature of 60 degrees Celsius and fully stir, The reaction is uniform to transparent and stable, and the stirring reaction takes 2.5 hours, and the extreme pressure lubricant is obtained by natural cooling.

[0035] (2) Weigh ethylene glycol, the extreme pressure lubricant, sodium nitrite, and water prepared in st...

Embodiment 2

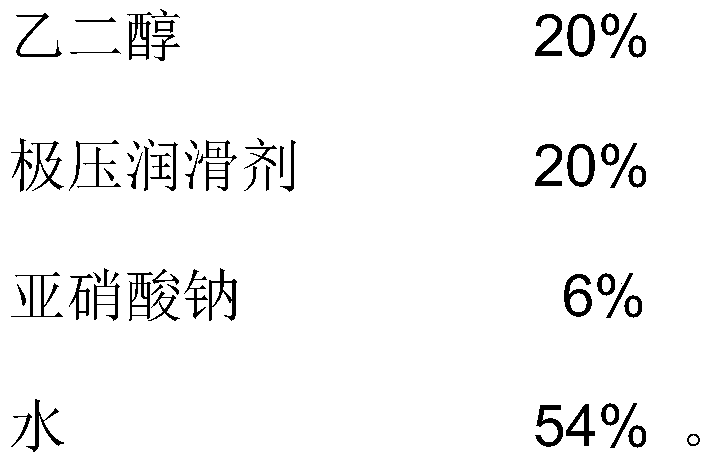

[0041] An improved high-performance environment-friendly antifreeze for hydraulic supports of the present embodiment is made of the following raw materials in terms of mass percentage:

[0042]

[0043] The extreme pressure lubricant is made of the following raw materials by mass percentage:

[0044]

[0045]

[0046] The preparation method of the antifreeze of the present embodiment is through the following steps:

[0047] (1) Preparation of extreme pressure lubricant: take glycerol, boric acid, potassium hydroxide, castor oil polyoxyethylene ether, water according to the required mass parts, and put the above-mentioned materials into the mixing tank at a temperature of 65 degrees Celsius to fully stir, The reaction is uniform to transparent and stable, and the stirring reaction takes 2.5 hours, and the extreme pressure lubricant is obtained by natural cooling.

[0048] (2) Weigh ethylene glycol, the extreme pressure lubricant, sodium nitrite, and water prepared in ...

Embodiment 3

[0051]An improved high-performance environment-friendly antifreeze for hydraulic supports of the present embodiment is made of the following raw materials by mass percentage:

[0052]

[0053] The extreme pressure lubricant is made of the following raw materials by mass percentage:

[0054]

[0055]

[0056] The preparation method of the antifreeze of the present embodiment is through the following steps:

[0057] (1) Preparation of extreme pressure lubricant: take glycerol, boric acid, potassium hydroxide, castor oil polyoxyethylene ether, water according to the required mass parts, put the above-mentioned materials into the stirring tank at a temperature of 70 degrees Celsius and fully stir, The reaction is uniform to transparent and stable, and the stirring reaction time is 2.5 hours, and the extreme pressure lubricant is obtained by natural cooling.

[0058] (2) Weigh ethylene glycol, the extreme pressure lubricant, sodium nitrite, and water prepared in the step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com