A kind of rare earth wear-resistant lubricating grease and preparation method thereof

A grease and rare earth technology, which is applied in the field of rare earth wear-resistant grease and its preparation, can solve the problems of poor interfacial compatibility and unfavorable dispersion of rare earth nanoparticles, and achieve improved dispersion, enhanced synergistic effect, excellent extreme pressure and The effect of anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a kind of rare earth wear-resistant lubricating grease, and described lubricating grease comprises: 0.05wt% of rare earth composite additive, thickener lithium stearate 12wt%, balance is base oil; Nanoparticles and organic acid; The content of rare earth is 2wt%; The rare earth includes rare earth lanthanum oxide; The content of the nanoparticle is 95wt%; The nanoparticle has a hydrotalcite-like (Mg / Al- LDHs); the content of the organic acid is 3wt%; the organic acid is ethylenediaminetetraacetic acid;

[0081] The preparation method of the rare earth wear-resistant grease is as follows:

[0082] (1) The rare earth and organic acid solution are mixed and subjected to microwave treatment to obtain a rare earth complex solution; wherein, the mass ratio of the rare earth to the organic acid solution is 1:1; the rare earth is a nanoscale rare earth; the organic The concentration of the acid is 4wt%; the organic acid has an amino polycarboxylic acid...

Embodiment 2

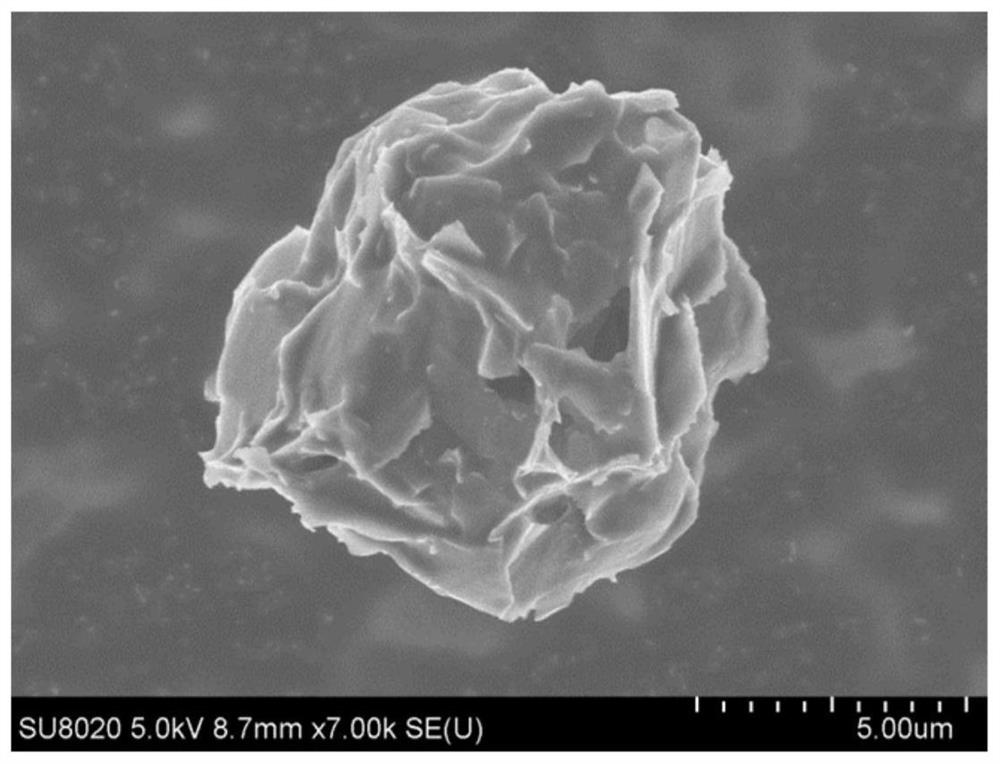

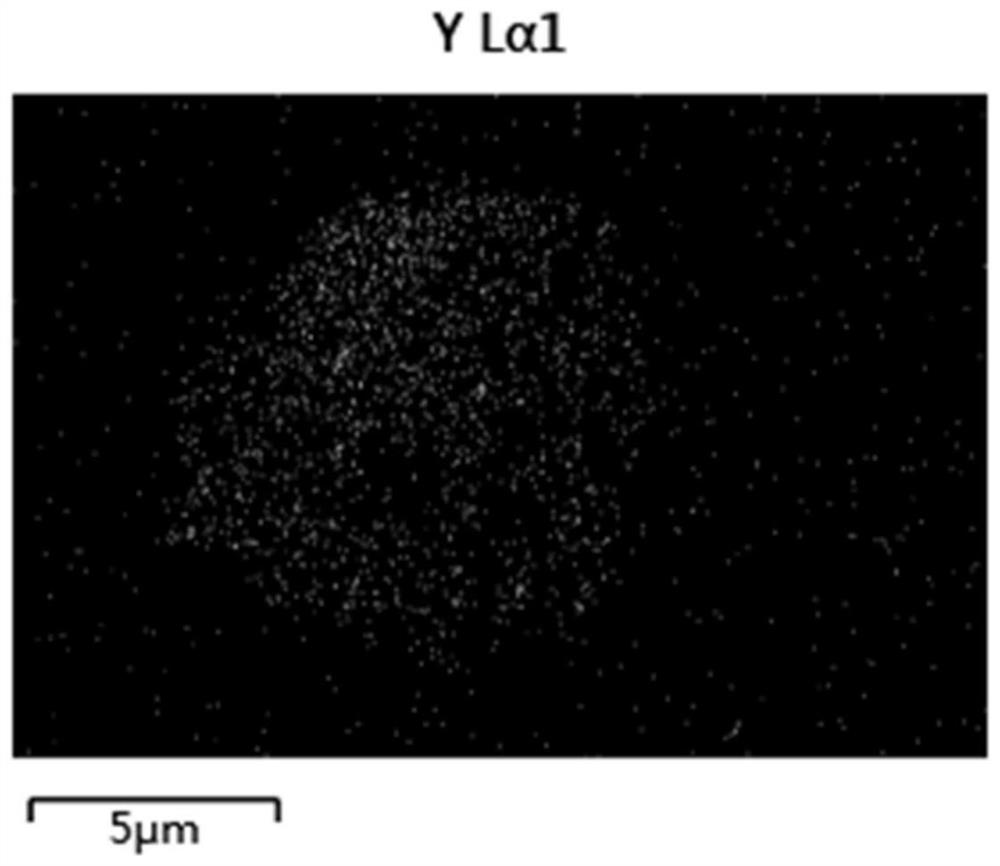

[0089] This embodiment provides a kind of rare earth wear-resistant lubricating grease, said lubricating grease comprises: rare earth composite additive 0.015wt%, thickening agent is 1,2 hydroxyl lithium stearate 12wt%, balance is base oil; The additive includes rare earths, nanoparticles and organic acids; the content of the rare earths is 1wt%; the rare earths include rare earth yttrium oxide; the content of the nanoparticles is 96wt%; the nanoparticles have graphene with a two-dimensional sheet structure; The content of the organic acid is 3wt%; the organic acid is ethylenediaminetetraacetic acid;

[0090] The preparation method of the rare earth wear-resistant grease is as follows:

[0091] (1) The rare earth and organic acid solution are mixed and subjected to microwave treatment to obtain a rare earth complex solution; wherein, the mass ratio of the rare earth to the organic acid solution is 1:1; the rare earth is a nanoscale rare earth; the organic The concentration of...

Embodiment 3

[0098] This embodiment provides a rare earth wear-resistant grease, the grease includes: 0.075wt% rare earth composite additive, 10wt% thickener, and the balance is base oil; the rare earth composite additive includes rare earth, nanoparticles and organic Acid; the content of rare earth is 3wt%; the rare earth includes rare earth cerium oxide; the content of the nanoparticles is 92wt%; the nanoparticles have molybdenum disulfide of two-dimensional lamellar structure; the content of the organic acid is 5wt %; The organic acid tool is diethylenetriaminepentaacetic acid;

[0099] The preparation method of the rare earth wear-resistant grease is as follows:

[0100](1) The rare earth and organic acid solution are mixed and subjected to microwave treatment to obtain a rare earth complex solution; wherein, the mass ratio of the rare earth to the organic acid solution is 1:1; the rare earth is a nanoscale rare earth; the organic The concentration of the acid is 2.5wt%; the organic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com