A vehicle gear lubricant with low sulfur and low shear viscosity loss

A technology of gear lubricating oil and low shear viscosity, which is applied in the chemical field and can solve problems affecting oil cleanliness and low temperature performance, high KRL shear loss, increased sludge and carbon deposits, etc., to achieve good sludge and carbon deposit control ability, solve the problem of unsmooth oil passage, and reduce the effect of sulfur addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

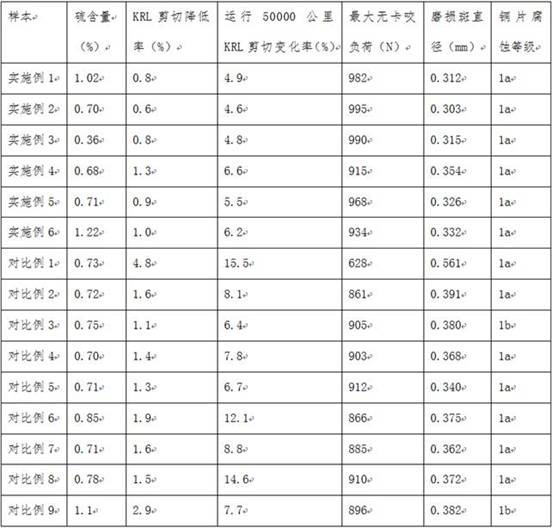

Examples

Embodiment 1

[0049]A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0050] Vehicle gear oil compound 6%

[0051] 1- Propylene and ethylene polymer 20%

[0052] High viscosity polyalphaolefin 30%

[0053] Synthetic ester 15%

[0054] Nano rare earth wear reducer 1%

[0055] Organic Friction Modifier 5%

[0056] Alkylated naphthalene (AN) 5%

[0057] Pour point depressant 0.3%

[0058] Demulsifier 0.01%

[0059] Defoamer 50ppm

[0060] Metal deactivator 0.05%

[0061] Rust inhibitor 0.05%

[0062] Antioxidant 0.1%

[0063] Base oil balance

[0064] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0065] The 1-propylene and ethylene polymer is LUCANT HC-100 from Mitsui Chemicals.

[0066] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and its kinematic viscosity at 100°C is 40cSt.

[0067] The kinematic viscosity of t...

Embodiment 2

[0084] A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0085] Vehicle gear oil compound 4%

[0086] 1- Propylene and ethylene polymer 30%

[0087] High viscosity polyalphaolefin 20%

[0088] Synthetic ester 10%

[0089] Nano rare earth wear reducer 3%

[0090] Organic Friction Modifier 3%

[0091] Alkylated naphthalene (AN) 10%

[0092] Pour-point depressant 0.5%

[0093] Demulsifier 0.03%

[0094] Defoamer 100ppm

[0095] Metal deactivator 0.08%

[0096] Rust inhibitor 0.3%

[0097] Antioxidant 0.5%

[0098] Base oil balance

[0099] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0100] The 1-propylene and ethylene polymer is LUCANT HC-600 from Mitsui Chemicals.

[0101] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and the kinematic viscosity at 100°C is 500cSt.

[0102] The kinematic viscosity o...

Embodiment 3

[0119] A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0120] Vehicle gear oil compound 2%

[0121] 1- Propylene and ethylene polymer 40%

[0122] High viscosity polyalphaolefin 15%

[0123] Synthetic ester 5%

[0124] Nano rare earth wear reducer 5%

[0125] Organic friction modifier 1%

[0126] Alkylated naphthalene (AN) 15%

[0127] Pour point depressant 1%

[0128] Demulsifier 0.05%

[0129] Defoamer 200ppm

[0130] Metal deactivator 0.1%

[0131] Rust inhibitor 0.5%

[0132] Antioxidant 1.0%

[0133] Base oil balance

[0134] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0135] The 1-propylene and ethylene polymer is LUCANT HC-2000 from Mitsui Chemicals.

[0136] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and the kinematic viscosity at 100°C is 1000cSt.

[0137] The kinematic viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com