Ester-containing benzothiazole derivative lubricating oil additive and preparation and application thereof

A lubricating oil additive, a technology containing ester-based benzene, applied in the directions of additives, lubricating compositions, petroleum industry, etc., to achieve the effects of mild reaction conditions, cheap and readily available raw materials, excellent thermal stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

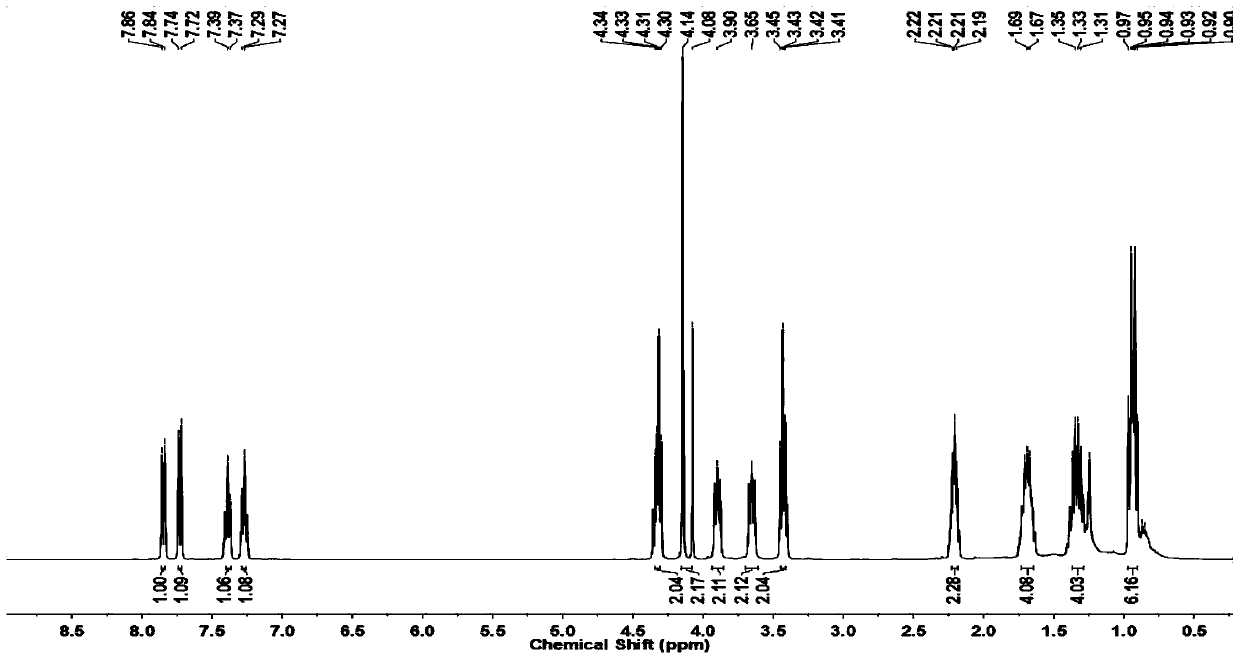

Embodiment 1

[0041] Add 0.05 mol (6.45 g) of di-n-butylamine, 0.06 mol (2.40 g) of sodium hydroxide and 50 mL of THF to a 250 mL three-necked flask in sequence, add 0.05 mol (3.80 g) of carbon disulfide dropwise in an ice bath, and stir for 3.0 h. After the reaction was completed, filter and remove the solvent by rotary evaporation of the filtrate to obtain arginine sodium salt.

[0042] Add 0.05mol (8.35g) 2-mercaptobenzothiazole and 60mL aqueous NaOH solution with a mass fraction of 10% to a 250mL three-necked flask in sequence, raise the temperature to 65°C, stir for 0.5h, and dropwise add 0.05mol (4.70g) 3-chloro-1 -propanol, heat up to 80°C and stir for 10h. After the reaction, filter, extract with ethyl acetate, wash with saturated brine several times, dry over anhydrous magnesium sulfate, filter, and remove the solvent to obtain 3-(benzothiazol-2-ylthio)propyl-1-ol.

[0043] Add 0.05mol (11.25g) 3-(benzothiazol-2-ylthio)propyl-1-ol, 0.06mol (6.06g) triethylamine, 60mL chloroform in...

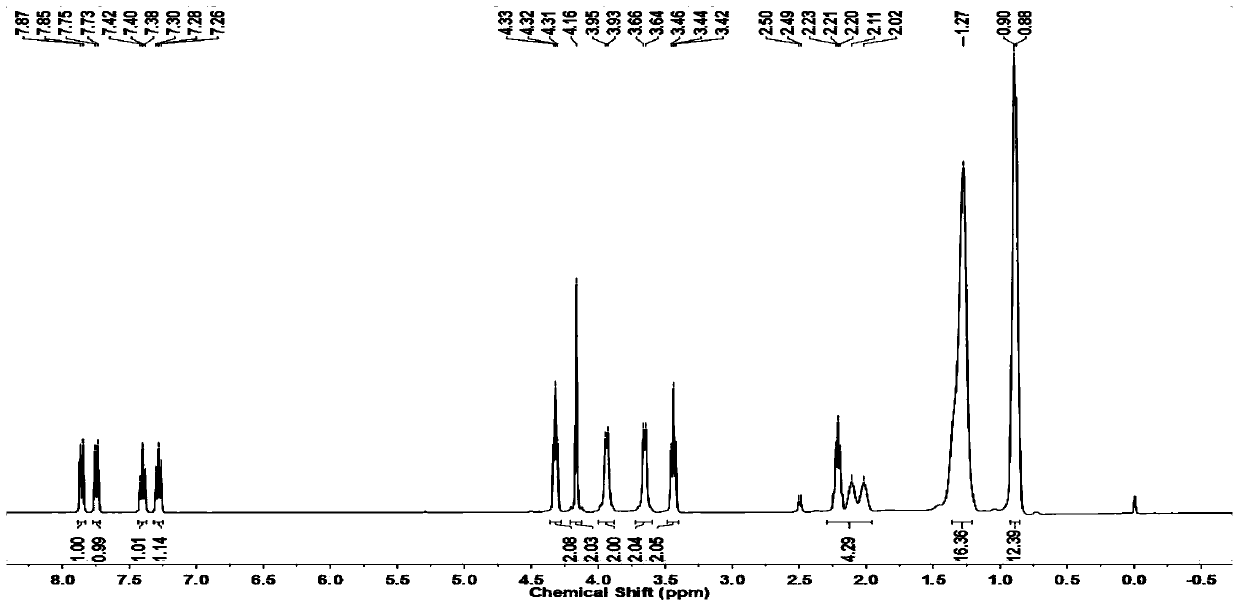

Embodiment 2

[0046] Add 0.05 mol (12.07 g) of diisooctylamine, 0.06 mol (2.40 g) of sodium hydroxide and 50 mL of THF to a 250 mL three-necked flask in sequence, add 0.05 mol (3.80 g) of carbon disulfide dropwise in an ice bath, and stir for 3.0 h. After the reaction was completed, filter and remove the solvent by rotary evaporation of the filtrate to obtain arginine sodium salt.

[0047] Add 0.05mol (8.35g) 2-mercaptobenzothiazole and 60mL aqueous NaOH solution with a mass fraction of 10% to a 250mL three-necked flask in sequence, raise the temperature to 65°C, stir for 0.5h, and dropwise add 0.05mol (4.70g) 3-chloro-1 -propanol, heat up to 80°C and stir for 10h. After the reaction, filter, extract with ethyl acetate, wash with saturated brine several times, dry over anhydrous magnesium sulfate, filter, and remove the solvent to obtain 3-(benzothiazol-2-ylthio)propyl-1-ol.

[0048] Add 0.05mol (11.25g) 3-(benzothiazol-2-ylthio)propyl-1-ol, 0.06mol (6.06g) triethylamine, 60mL chloroform in ...

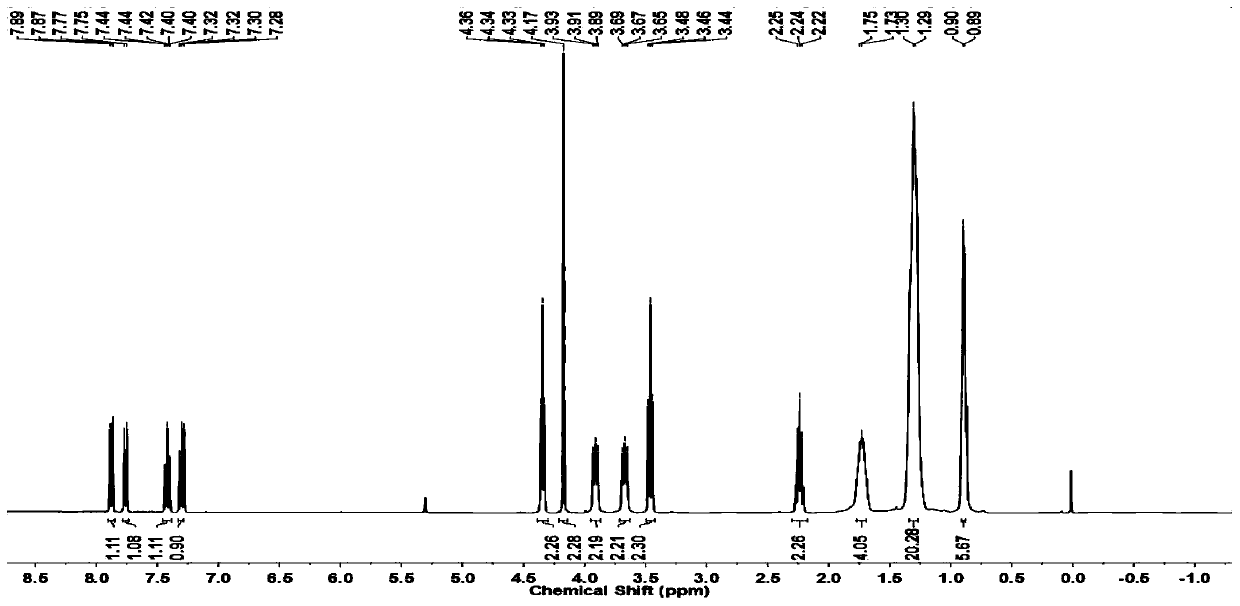

Embodiment 3

[0051] Add 0.05 mol (12.07 g) of di-n-octylamine, 0.06 mol (2.40 g) of sodium hydroxide and 50 mL of THF to a 250 mL three-necked flask in sequence, add 0.05 mol (3.80 g) of carbon disulfide dropwise in an ice bath, and stir for 3.0 h. After the reaction was completed, filter and remove the solvent by rotary evaporation of the filtrate to obtain arginine sodium salt.

[0052] Add 0.05mol (8.35g) 2-mercaptobenzothiazole and 60mL aqueous NaOH solution with a mass fraction of 10% to a 250mL three-necked flask in sequence, raise the temperature to 65°C, stir for 0.5h, and dropwise add 0.05mol (4.70g) 3-chloro-1 -propanol, heat up to 80°C and stir for 10h. After the reaction, filter, extract with ethyl acetate, wash with saturated brine several times, dry over anhydrous magnesium sulfate, filter, and remove the solvent to obtain 3-(benzothiazol-2-ylthio)propyl-1-ol.

[0053] Add 0.05mol (11.25g) 3-(benzothiazol-2-ylthio)propyl-1-ol, 0.06mol (6.06g) triethylamine, 60mL chloroform i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com