Method for preparing lithium-based (lithium-based calcium-based) lubricating grease by using waste vegetable oil and application

A lithium-based calcium-based grease, lithium-based calcium-based grease technology, applied in lubricating compositions, petroleum industry, thickeners, etc., to achieve a good extreme pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

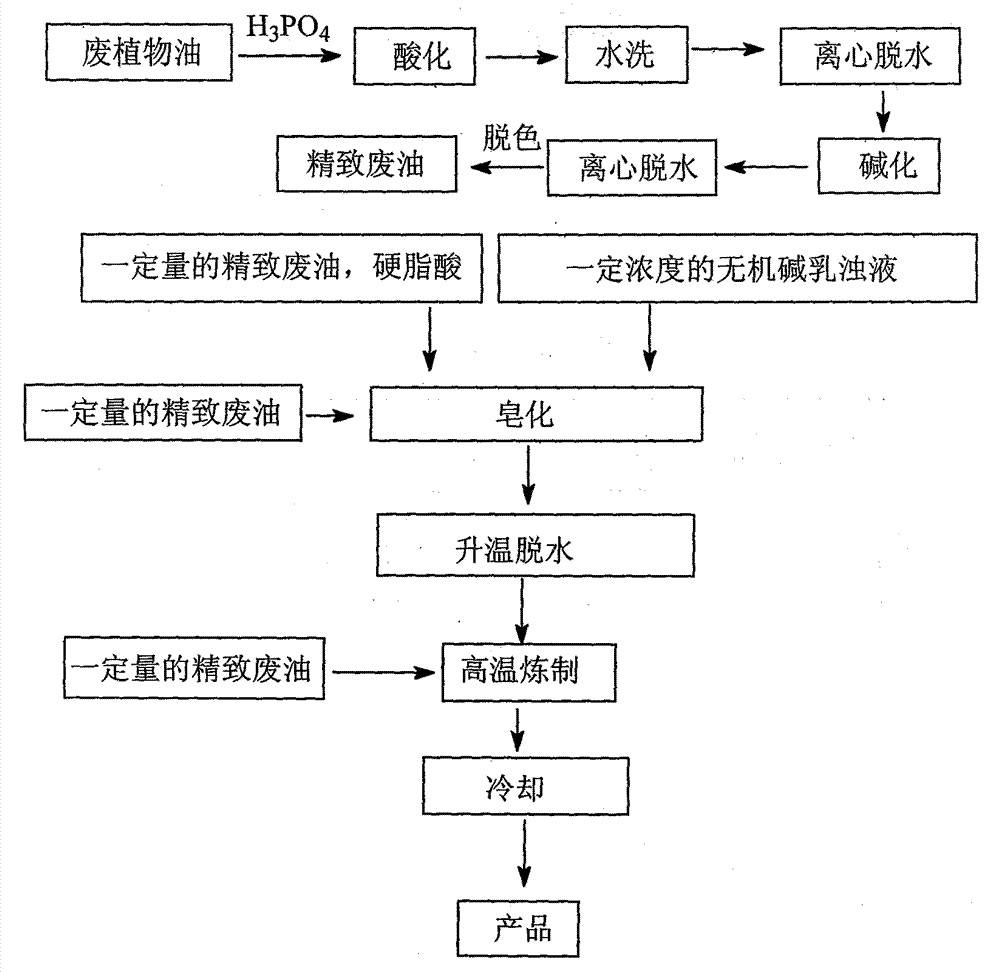

Image

Examples

example 1

[0020] Example 1: Take 297.9g of waste vegetable oil, remove solid residue impurities by suction filtration, stir and add 2.38g of phosphoric acid at 60°C for degumming, stir evenly and let stand for 8h, filter, add 30.0g of water to the filtrate and stir for 1.5h, then Centrifuge the oil and water samples (rotating speed: 4000r / min), take the upper oil sample and heat it at 100-110°C for 1.0h to remove all the water in the oil to obtain a light orange milky liquid. Add 23.59 g of 10.5% NaOH solution to the supernatant to neutralize unreacted H 3 PO 4 , followed by adding 16.07 g of 10% NaCl aqueous solution, standing for 7 hours, filtering, adding 27.0 g of distilled water into the clear liquid under stirring, and obtaining an orange-yellow translucent supernatant after centrifugal dehydration. Heat the clear liquid at 110°C to remove water for 1.0h, add an appropriate amount of activated carbon to decolorize at 104-110°C for 30 minutes, cool to 70-80°C and remove the activa...

example 2

[0022] Example 2: Take 159.7g of waste vegetable oil, remove solid residue impurities by suction filtration, stir and add 1.30g of phosphoric acid at 60°C for degumming, after stirring evenly, let stand for 8h and then filter, add 16.0g of water to the filtrate, stir for 2.0h , and then separate the oil and water samples on a centrifuge with a speed of 4000r / min, take the upper oil sample and heat it at 100-110°C for 1.0h to remove all the water in the oil to obtain a light orange milky clear liquid. Add 12.89 g of 10.5% NaOH solution to the supernatant to neutralize unreacted H 3 PO 4 , Then add 86.94g of 10% NaCl aqueous solution and let it stand for 6h. Filter, add 15.00 g of distilled water to the clear liquid under stirring, and obtain an orange-yellow translucent supernatant after centrifugal dehydration. Heat the supernatant at 110°C to remove water for 1.0h, add an appropriate amount of activated carbon to decolorize at 104-110°C for 30 minutes, cool to 70-80°C and r...

example 3

[0024] Example 3: Take 271.6g of waste vegetable oil, remove solid residue impurities by suction filtration, stir and add 2.17g of phosphoric acid at 65°C for degumming, after stirring evenly, let stand for 8h and then filter, add 27.20g of water to the filtrate and stir for 1.5h , and then separate the oil and water samples on a centrifuge with a rotational speed of 4000r / min, take the upper oil sample and heat it at 100-110°C for 1.0h to remove all the water in the oil to obtain a light orange milky serum. Add 21.71 g of 10.5% NaOH solution to the supernatant to neutralize unreacted H 3 PO 4 , followed by adding 14.87 g of 10% NaCl aqueous solution and standing for 8 hours. Filter, add 27.16 g of distilled water to the clear liquid under stirring, and obtain an orange-yellow translucent supernatant after centrifugal dehydration. Heat the supernatant at 110°C for 1.0h to remove water, add an appropriate amount of activated carbon to decolorize at 104-110°C for 30 minutes, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com