Complex lithium base grease and preparation method thereof

A complex lithium-based grease technology, applied in the field of grease, can solve the problems of low production efficiency, long heating and dehydration time, and large energy consumption of complex lithium-based grease, achieving good mechanical stability, fast and sufficient saponification reaction, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

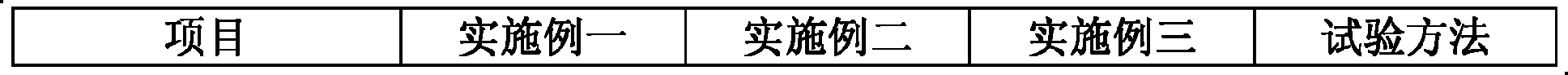

Examples

Embodiment 1

[0023] Embodiment one: a kind of preparation method of composite lithium base lubricating grease comprises the following processing steps:

[0024] (1) Saponification: Add 118g of base oil in the reactor: polyalphaolefin and 22g of dibasic organic acid: sebacic acid, heat up to 130°C, and the heating time is 10min, so that dibasic organic acid: sebacic acid is completely Melt; add 55g monobasic organic acid: lauryl hydroxystearic acid, react for 3min; add 118g base oil: polyalphaolefin, make the material in the reactor cool to 85 ℃, add 27.5g lithium hydroxide oil solution to carry out saponification, saponification The temperature is 100°C, after 10 minutes of reaction;

[0025] (2) Rapidly heat up the reactor to 200°C, the heating rate is: 1°C / min, keep the constant temperature for 10min, add 118g of base oil: polyalphaolefin, move the material in the reactor to the intermediate kettle, and transfer it to Add 118g of base oil: polyalphaolefin into the intermediate kettle, a...

Embodiment 2

[0027] Embodiment two: a kind of preparation method of composite lithium base lubricating grease comprises the following processing steps:

[0028] (1) Saponification: add 117g of base oil to the reactor: 150BS and 30g of dibasic organic acid: sebacic acid, heat up to 135°C, and heat up for 5min to completely melt the dibasic organic acid: sebacic acid; Add 72g of monobasic organic acid: lauryl hydroxystearic acid, and react for 5 minutes; add 117g of base oil: 150BS, cool the material in the reactor to 82°C, add 35.8g of lithium hydroxide oil solution for saponification, and the saponification temperature is 102°C , after 12 minutes of reaction;

[0029] (2) Rapidly raise the temperature of the reactor to 205°C, the heating rate is: 2°C / min, keep the constant temperature for 12min, add 117g of base oil: 150BS, move the materials in the reactor to the intermediate kettle, and transfer them to the intermediate kettle Add 117g of base oil: 150BS, and carry out circulating cooli...

Embodiment 3

[0031] Embodiment three: a kind of preparation method of composite lithium base lubricating grease comprises the following processing steps:

[0032] (1) Saponification: Add 110g of base oil in the reactor: polyalphaolefin and 36g of dibasic organic acid: sebacic acid, heat up to 140°C, and the heating time is 8min, so that dibasic organic acid: sebacic acid is completely Melt; add 84g monobasic organic acid: stearic acid, react for 4min; add 110g base oil: polyalphaolefin, make the material in the reactor cool to 85 ℃, add 38g lithium hydroxide oil solution to carry out saponification, saponification temperature is 105 ℃ , after reacting for 15min; the mass percent concentration of the lithium hydroxide oil solution is 35%;

[0033] (2) The reactor is rapidly heated to 210°C, the heating rate is 2°C / min, and the constant temperature is maintained for 15min. After adding 110g of base oil: polyalphaolefin, the materials in the reactor are moved to the intermediate kettle, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com