Preparation method of low-cloud-point fatty acid type diesel antiwear additive

A technology of fatty acid and antiwear agent, which is applied in the field of preparation of low cloud point fatty acid type diesel oil antiwear agent, and can solve problems such as difficult separation, difficult separation, easy turbidity of filtrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

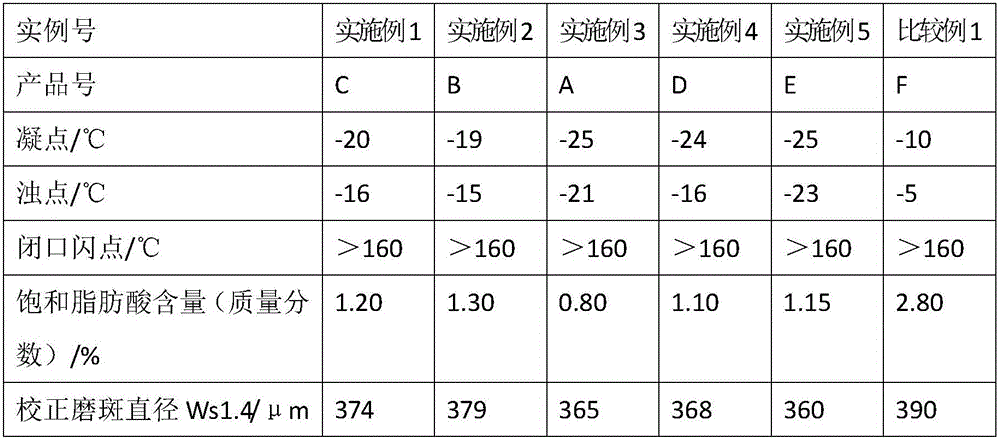

Examples

Embodiment 1

[0018] Put 1000 grams of commercially available industrial oleic acid (condensation point 4°C, saturated fatty acid content 5.0%) and 0.5 grams of polyalphaolefin (molecular weight is 70,000) into a 2-liter reactor with a jacket, stir and mix while passing Jacket cooling, stop stirring when the material reaches -8°C, start stirring after 4 hours, release the material and filter to separate the crystals, the crystals are loose and fluid. Add 50 grams of mineral spirits with a flash point of 60° C. and 0.5 gram of polymethacrylate (T602) into the obtained filtrate, and mix uniformly to obtain product A.

Embodiment 2

[0020] Put 1000 grams of commercially available industrial oleic acid (condensation point 4°C, saturated fatty acid content 5.0%) and 0.1 gram polyalphaolefin (molecular weight: 100,000) into a 2-liter reactor with a jacket, stir and mix while passing Jacket cooling, stop stirring when the material reaches -5°C, start stirring after standing for 6 hours, release the material and filter to separate the crystals, the crystals are loose and fluid. Add 50 grams of mineral spirits with a flash point of 60° C. and 0.1 gram of polymethacrylate (T602) to the obtained filtrate, and mix uniformly to obtain product B.

Embodiment 3

[0022] Put 1000 grams of commercially available industrial oleic acid (condensation point 4°C, saturated fatty acid content 5.0%) and 0.1 gram polyalphaolefin (molecular weight: 100,000) into a 2L reactor with a jacket, stir and mix while passing through the jacket Cool in a jacket, stop stirring when the material reaches -10°C, start stirring after standing for 4 hours, release the material and filter to separate the crystals, the crystals are loose and fluid. Add 50 grams of mineral spirits with a flash point of 60° C. and 1.0 gram of polymethacrylate (T602) into the obtained filtrate, and mix well to obtain product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com