Extreme pressure antiwear additive and preparation method and application thereof

A technology of extreme pressure antiwear agent and acid binding agent, applied in chemical instruments and methods, additives, petroleum industry, etc. The problem of low strength and high activity of di-n-butyl phosphite can achieve the effect of good oil solubility, excellent anti-wear performance, thermal oxidation stability and good thermal oxidation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

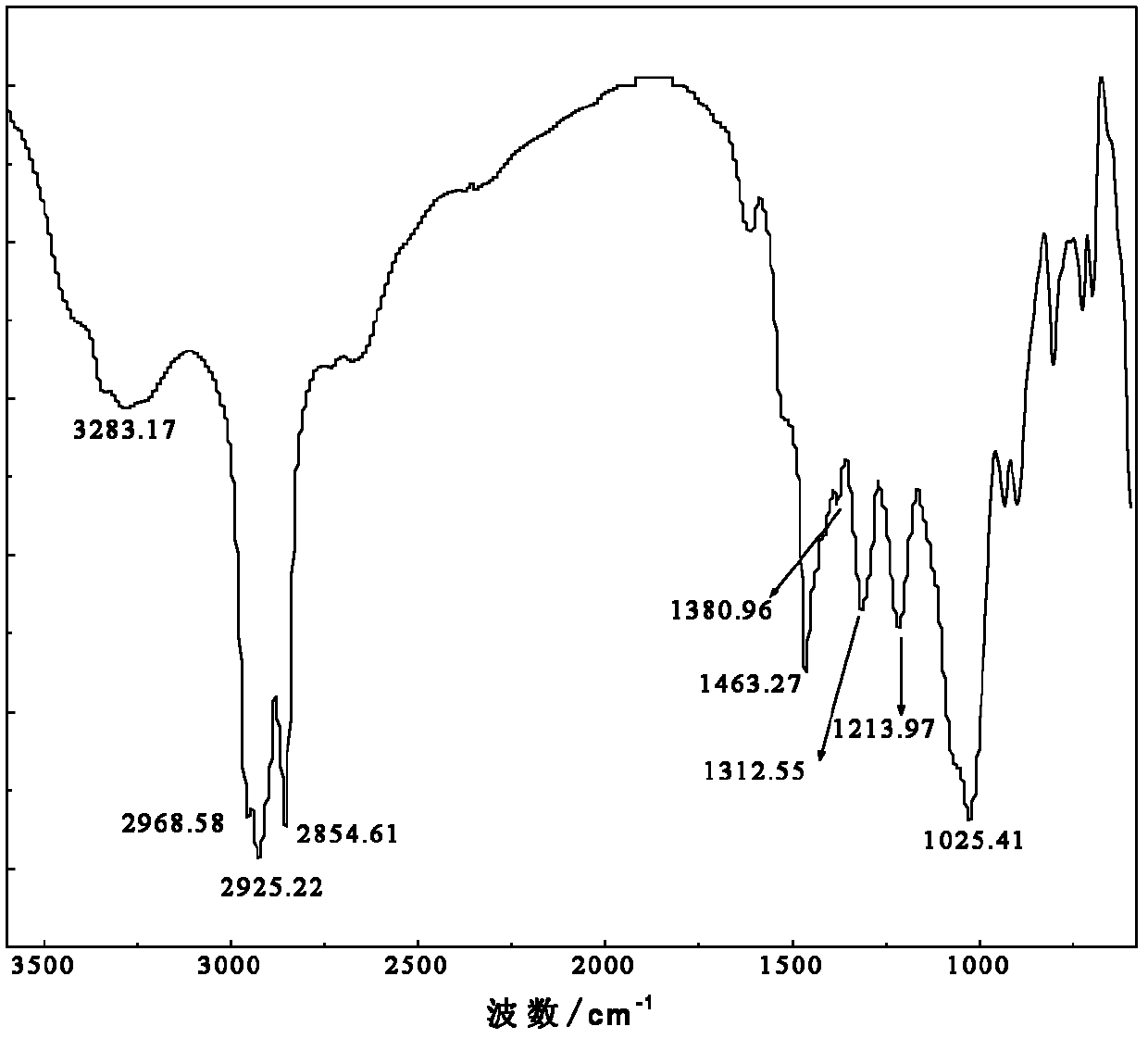

[0042] The preparation method of n-octyloxy (dodecyltriazole) phosphate derivative is as follows:

[0043] Take 0.3 mol of phosphorus oxychloride and 200 ml of toluene, add 0.3 mol of n-octanol and 0.6 mol of tetrabutylammonium bromide with stirring at a temperature of 0~10℃, stir at 40℃~50℃ for 2h, and collect 250Pa by vacuum distillation The liquid with the lower distillation range in the range of 110-115°C is the intermediate of di-n-octyloxy phosphate. Add dodecylamine and tetrabutylammonium bromide successively to the phosphate and 200ml ethylbenzene at a temperature of 5℃~15℃, react at 10℃~15℃ for 2h, and react at 50℃~60℃ 3h, then add benzotriazole powder and react at 115℃~135℃ for 2h. Nitrogen protection is required during the entire reaction and distillation process. After the reaction is completed, it is filtered, washed, dried and purified, and the obtained yellow transparent liquid is an anti-wear additive n-octyloxy (dodecyltriazole) phosphate derivative, and the co...

Embodiment 2

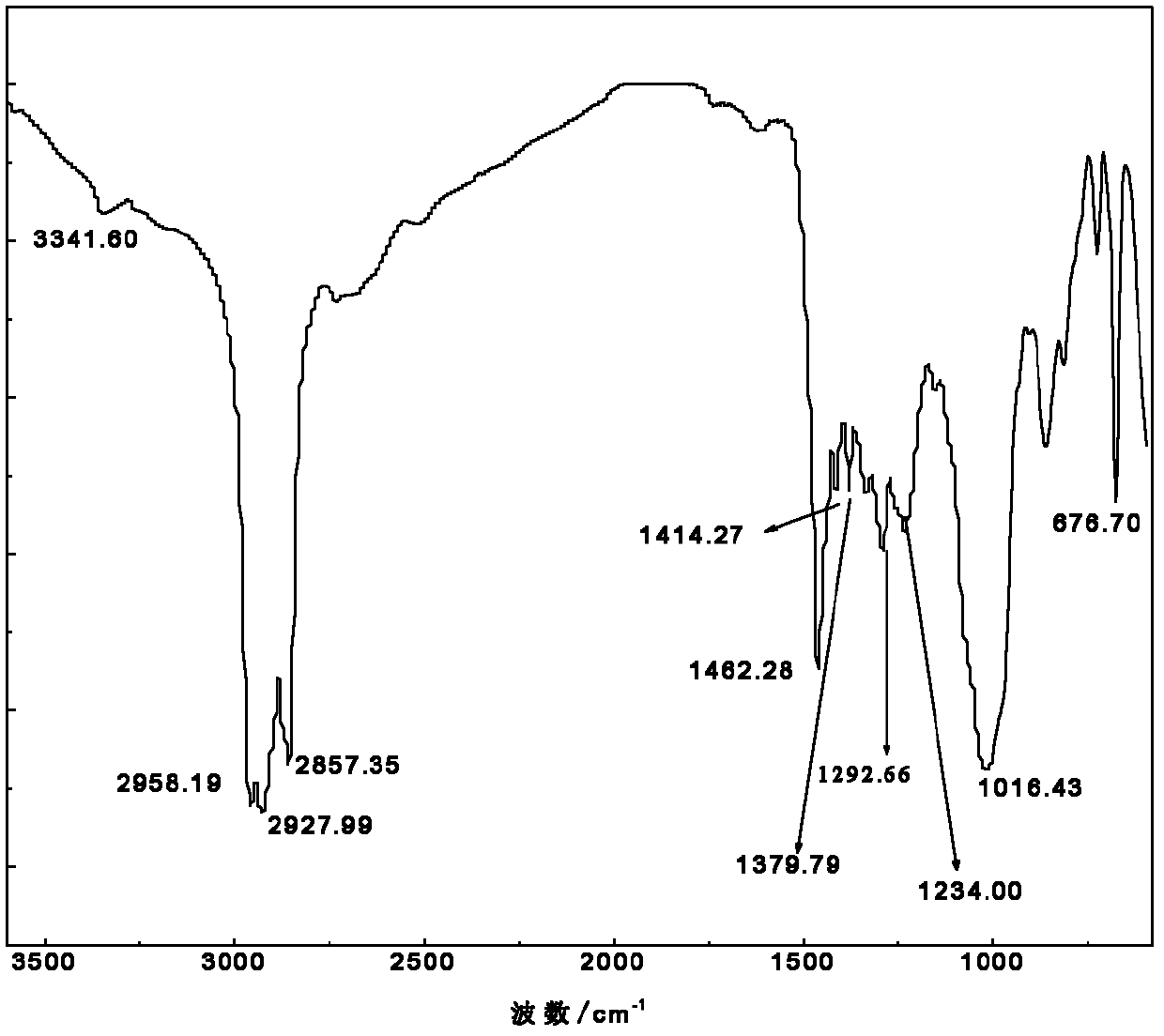

[0045] The preparation method of n-butoxy (cyclohexylaminomethylbenzenetriazole) phosphate derivative is as follows:

[0046] Take 0.3 mol of phosphorus oxychloride, 250 ml of ether, add 0.6 mol of n-butanol and 0.4 mol of sodium hydroxide with stirring at 5~15℃, stir at 50℃~60℃ for 2h, collect under reduced pressure and distill at 250Pa, the distillation range is 100- The liquid within the range of 110°C is the di-n-butoxy phosphate intermediate. At 10℃~20℃, add cyclohexylamine and sodium hydroxide to the phosphate and 200ml ethylbenzene successively, react at 15℃~30℃ for 2h, react at 50℃~60℃ for 3h, then add The tolyltriazole powder was reacted at 120℃~135℃ for 4h. Nitrogen protection is required during the entire reaction and distillation process. After the reaction is completed, after filtering, washing, drying and purifying, the obtained yellow transparent liquid is an anti-wear additive n-butoxy (cyclohexylamine methyl benzene triazole) phosphate derivative, and the code ...

Embodiment 3

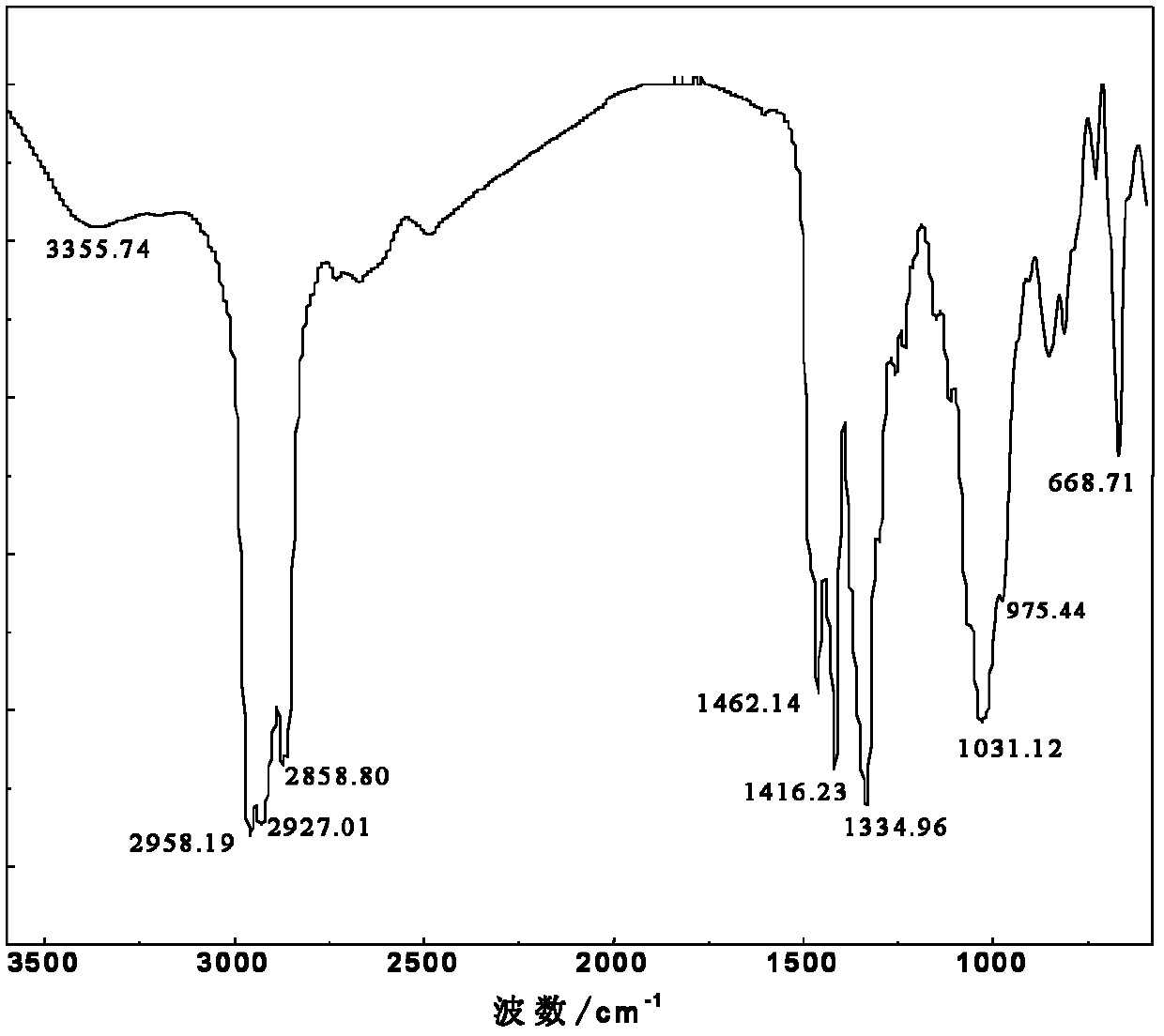

[0048] Isooctyloxy (tridecyl tertiary carbon primary benzotriazole) phosphate derivative, the preparation method is as follows:

[0049] Take 0.3 mol of phosphorus oxychloride and 200 ml of toluene, add 0.3 mol of isooctyl alcohol and 0.6 mol of triethylamine with stirring at a temperature of 10 to 20 ℃, stir at 50 ℃ to 60 ℃ for 3 hours, and collect under reduced pressure distillation at 250 Pa. The liquid within the range of 110-120°C is the intermediate of isooctyloxy phosphate. Add tridecyl tertiary carbon primary amine and triethylamine successively to the phosphoric acid ester and 200ml ethylbenzene at 10℃~20℃, and react at 15℃~20℃ for 2h, at 50℃~60℃ React for 3h, then add benzotriazole powder and react at 120℃~135℃ for 4h. Nitrogen protection is required during the entire reaction and distillation process. After the reaction is completed, it is filtered, washed, dried and purified, and the obtained yellow transparent liquid is an anti-wear additive isooctyloxy (tridecyl t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com