Boronation phosphoryl phosphor hydrazide ester, preparing method and application of the same

A technology of boronated phosphoryl phosphoryl hydrazide ester and dialkoxy phosphorothioate, which is applied to boronated phosphoryl phosphoryl hydrazide ester and its preparation and application fields, and can solve the extreme pressure and anti-wear properties of phosphate ester amine salt It can solve the problems of poor thermal stability, low tricresyl phosphate oil film strength, and high activity of di-n-butyl phosphite, so as to achieve the effects of good oil solubility, excellent anti-wear performance, thermal oxidation stability, and good thermal oxidation stability.

Active Publication Date: 2010-12-01

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the widely used ashless anti-wear additives of lubricating oil (grease) mainly include di-n-butyl phosphite (T304), tricresyl phosphate (T306), sulfuric acid-formaldehyde-amine condensate (T305), sulfuric acid Double ester amine salt (T307), phosphate ester amine salt (T308B), etc., there are not many varieties, and each has its own disadvantages, such as di-n-butyl phosphite is too active, and the corrosion is serious during use; tricresyl phosphate oil film strength is not good High; thiophosphoric acid-formaldehyde-amine condensate, thiophosphoric acid double ester amine salt has a very bad smell; phosphate ester amine salt has poor extreme pressure anti-wear performance and thermal stability, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

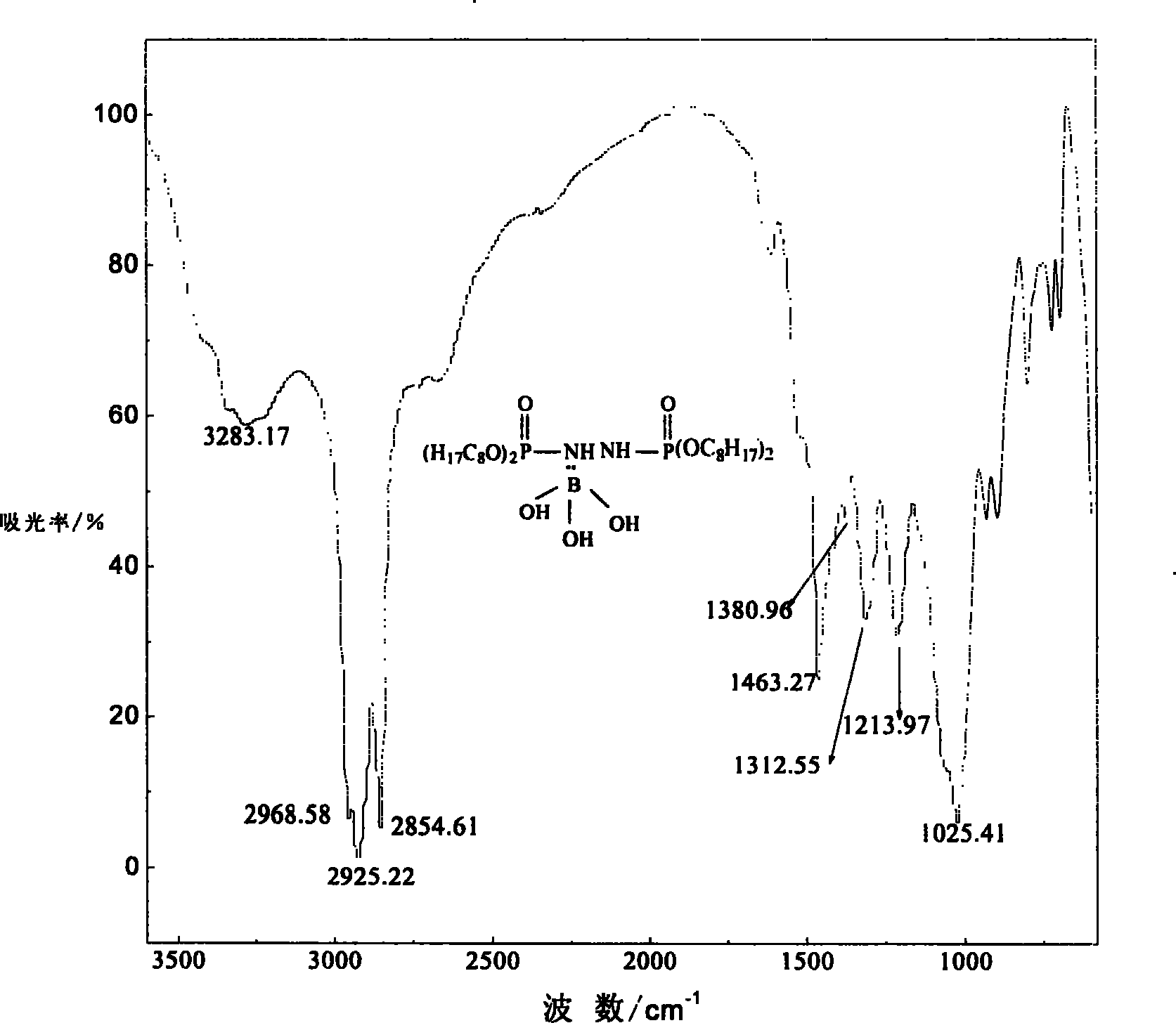

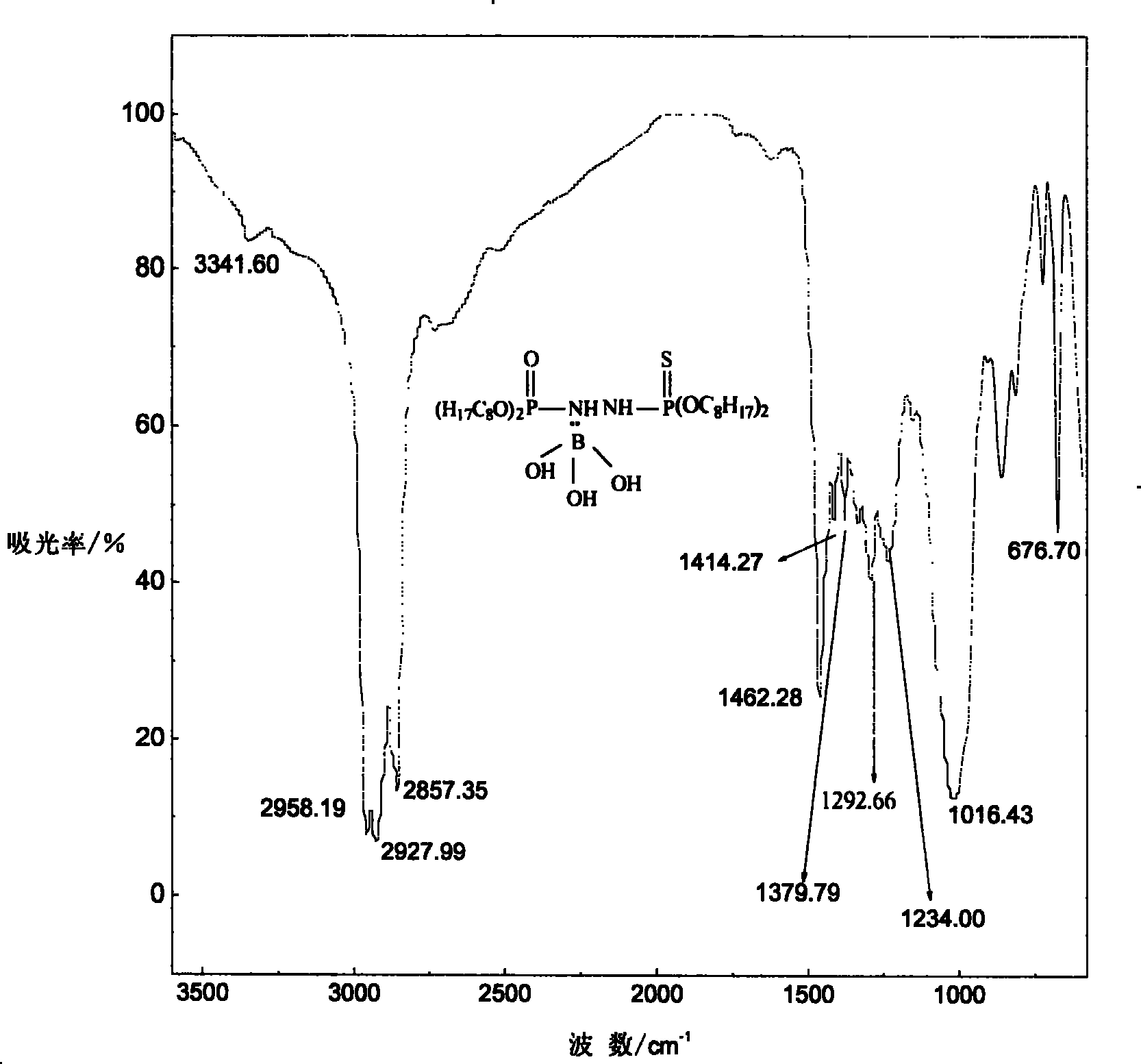

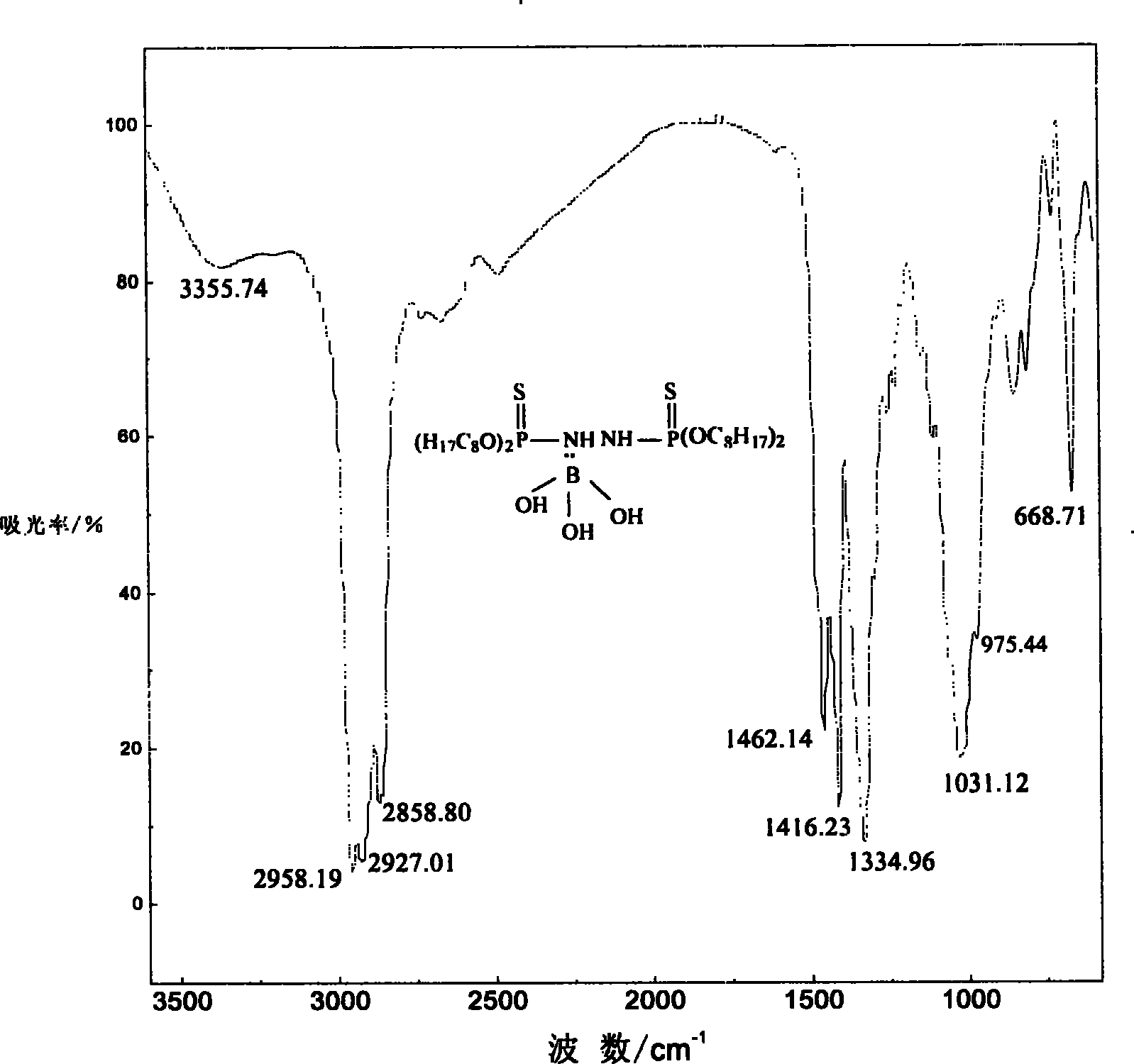

The present invention provides a phosphorus diboride hydrazide acyl phosphate ester compound. The compound has a structure as shown in the right general formula. In the formula, R1, R2, R3 and R4 are the same or different C1 to C20 alkyl; X and Y are O or S; X, Y can be the same and can be different. The phosphorus diboride hydrazide acyl phosphate ester compound of the present invention is synthesized by the reaction of phosphorus oxychloride or trichloro parathion, alcohol category of C1 to C20, hydrazine hydrate and boric acid. The compound of the present invention can be used as extreme pressure anti-wear agent in lubricant and grease; the recommended dosage is 0.1 weight percent to 2.0 weight percent.

Description

Phosphoryl phosphoryl hydrazide boride and its preparation method and application technical field The invention relates to a phosphorohydrazide compound, a preparation method thereof and an application method as an extreme pressure antiwear agent. Background technique At present, the widely used ashless anti-wear additives of lubricating oil (grease) mainly include di-n-butyl phosphite (T304), tricresyl phosphate (T306), sulfuric acid-formaldehyde-amine condensate (T305), sulfuric acid Double ester amine salt (T307), phosphate ester amine salt (T308B), etc., there are not many varieties, and each has its own disadvantages, such as di-n-butyl phosphite is too active, and the corrosion is serious during use; tricresyl phosphate oil film strength is not good High; thiophosphoric acid-formaldehyde-amine condensate, thiophosphoric acid double ester amine salt has a very bad smell; phosphate ester amine salt has poor extreme pressure anti-wear performance and thermal stability. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M137/08C07F5/02C07F9/24

Inventor 段庆华李云鹏王明江

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com