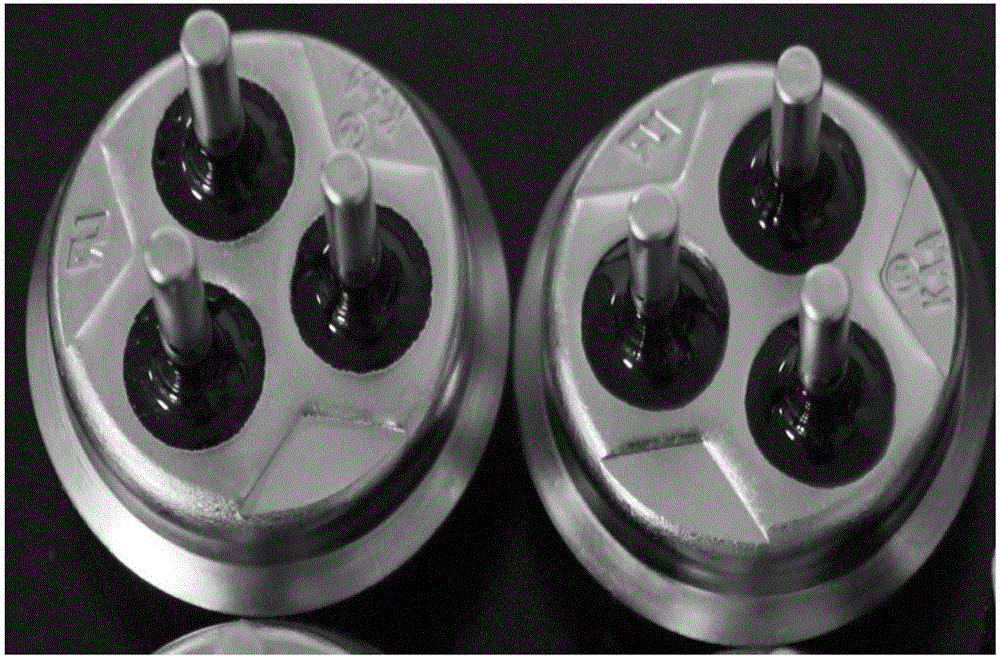

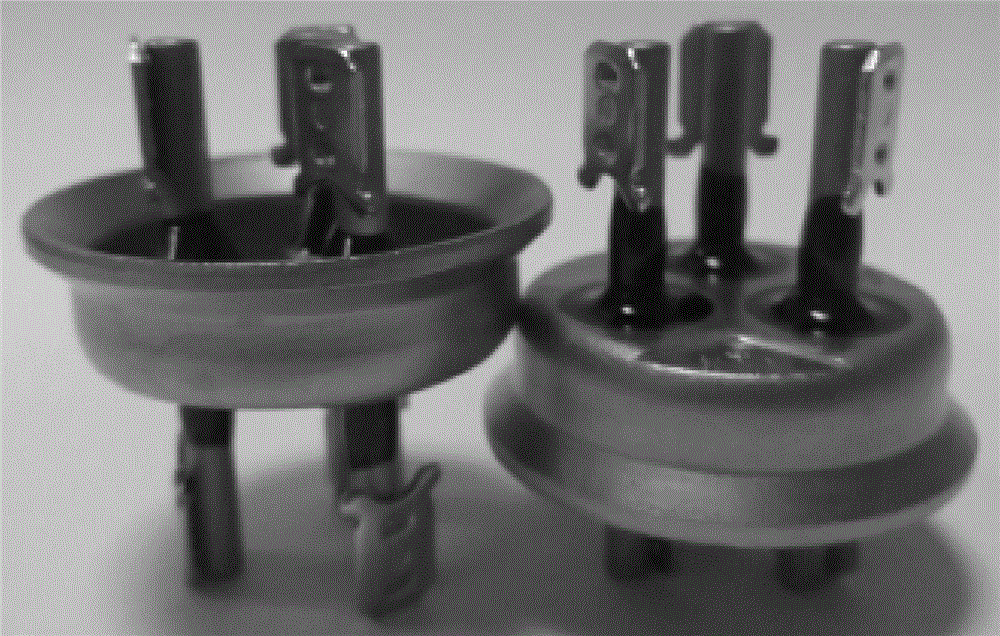

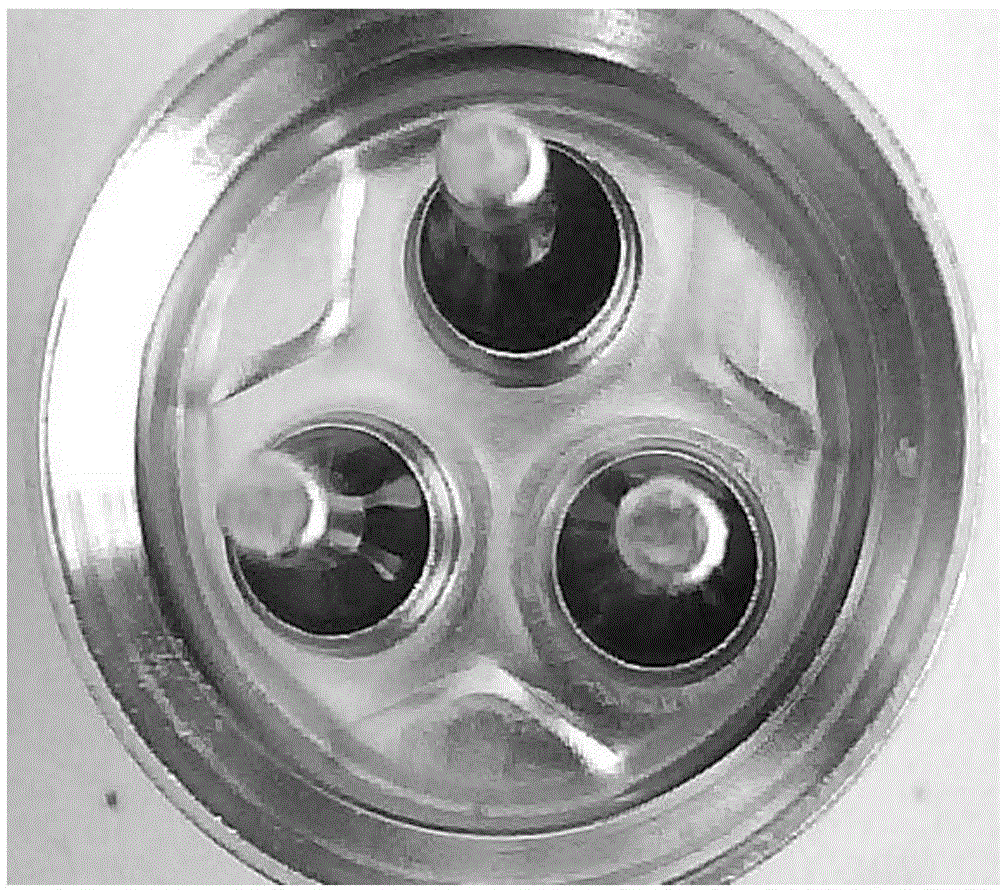

A kind of environment-friendly high-phosphorus electroless nickel plating solution and its application for hermetic glass-sealed terminal

A technology of electroless nickel plating solution and terminal, which is applied in the field of electroless plating. It can solve the problems of poor bonding force of steel needle plating, difficult welding of steel needle plating, environmental protection, etc., and achieve excellent welding, good stability of plating solution, and extended service life. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The implementation process of the present invention is strictly controlled according to the terminal electroless plating process, including the processes of alkaline oxidation, acid etching, activation, neutralization, electroless nickel plating and air-drying of the sintered airtight glass-sealed terminal, wherein,

[0032] The process conditions of the alkaline oxidation treatment step: KMnO4: 70-80g / L, NaOH: 100-120g / L, the temperature is 88-95°C, and the time is 60-90min.

[0033] Process conditions for acid etching: hydrochloric acid with a concentration of 35-45%, rhodin which accounts for 3% of the mass of hydrochloric acid, the control temperature is 45-55°C, and the time is 7-9min.

[0034] Activation process conditions: concentration of 25-35% hydrochloric acid, control temperature of 45-55°C, time of 1.5-2min.

[0035] Neutralization process conditions: adjust the pH to 12-13 with ammonia water, and control the temperature at 60-80°C.

[0036] Water washing ...

Embodiment 2-3

[0049]Compared with Example 1, the difference is that the main and auxiliary complexing agent and the composite stabilizing brightener are adjusted, and the others remain unchanged. As in Table 3:

[0050] table 3

[0051] Material name

Example 2

Example 3

Lactic acid (g / L)

41.2

43.8

Trisodium citrate (g / L)

1.5

2.63

Malic acid(g / L)

13.2

15

Glycine (g / L)

8.3

11.2

[0052] SnCl(g / L)

0.27

0.3

Maleic anhydride (g / L)

0.26

0.33

DEP (mg / L)

3

5

OP-10(ml / L)

0.23

0.36

[0053] After testing (5L beakers simulated trial production of 30 samples and 5 samples each) and tests, the results are shown in Table 4:

[0054] Table 4

[0055]

[0056] With reference to Table 4, from the test situation, when using the configuration parameters to go offline, the strong activity of the plating solution is conducive to improving the plating speed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com