Phosphamide ester extreme pressure anti-wear additives and preparation and application thereof

An extreme pressure antiwear agent, phosphoramidite technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problem of low strength of tricresyl phosphate oil film, high activity of di-n-butyl phosphite, odor, etc. problem, to achieve excellent anti-wear performance, good oil solubility, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

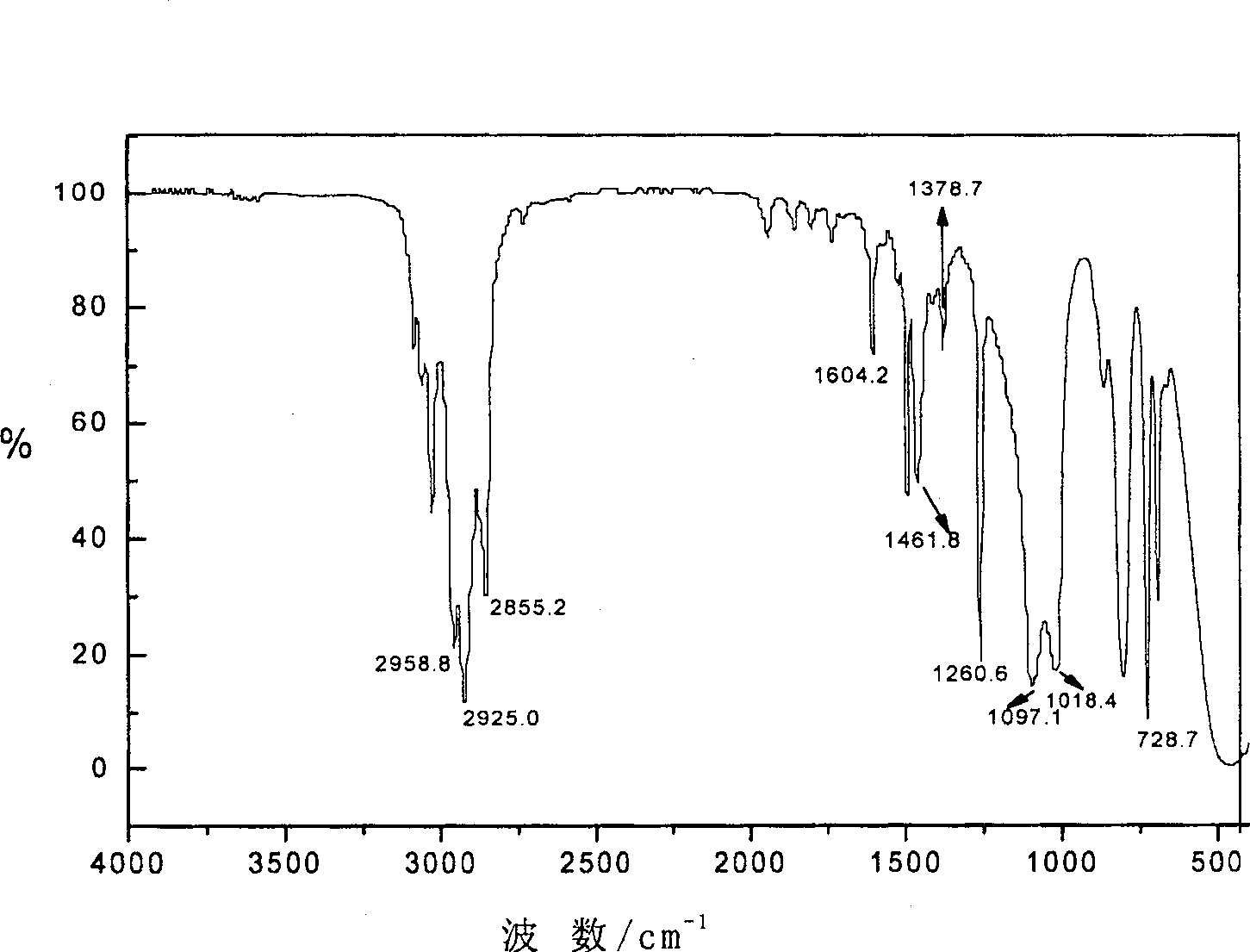

example 1

[0036] Take 0.3mol phosphorus oxychloride and 200ml toluene, stir and add 0.3mol n-octanol at a temperature of 0±5°C, stir and add 0.3mol lauryl alcohol and 0.6mol triethylamine after 3 hours, stir and add 0.33mol hydration after another 3 hours Hydrazine, heat up to 110±5°C for 1 hour to react for 1 hour, wash, dry, and purify. The obtained colorless transparent viscous liquid is the anti-wear additive n-octyl n-dodecylphosphorylhydrazide, code-named A1. Add A1 to N46 base oil at 0.50w%, and evaluate it with a four-ball tester. The results are shown in Table 1;

example 2

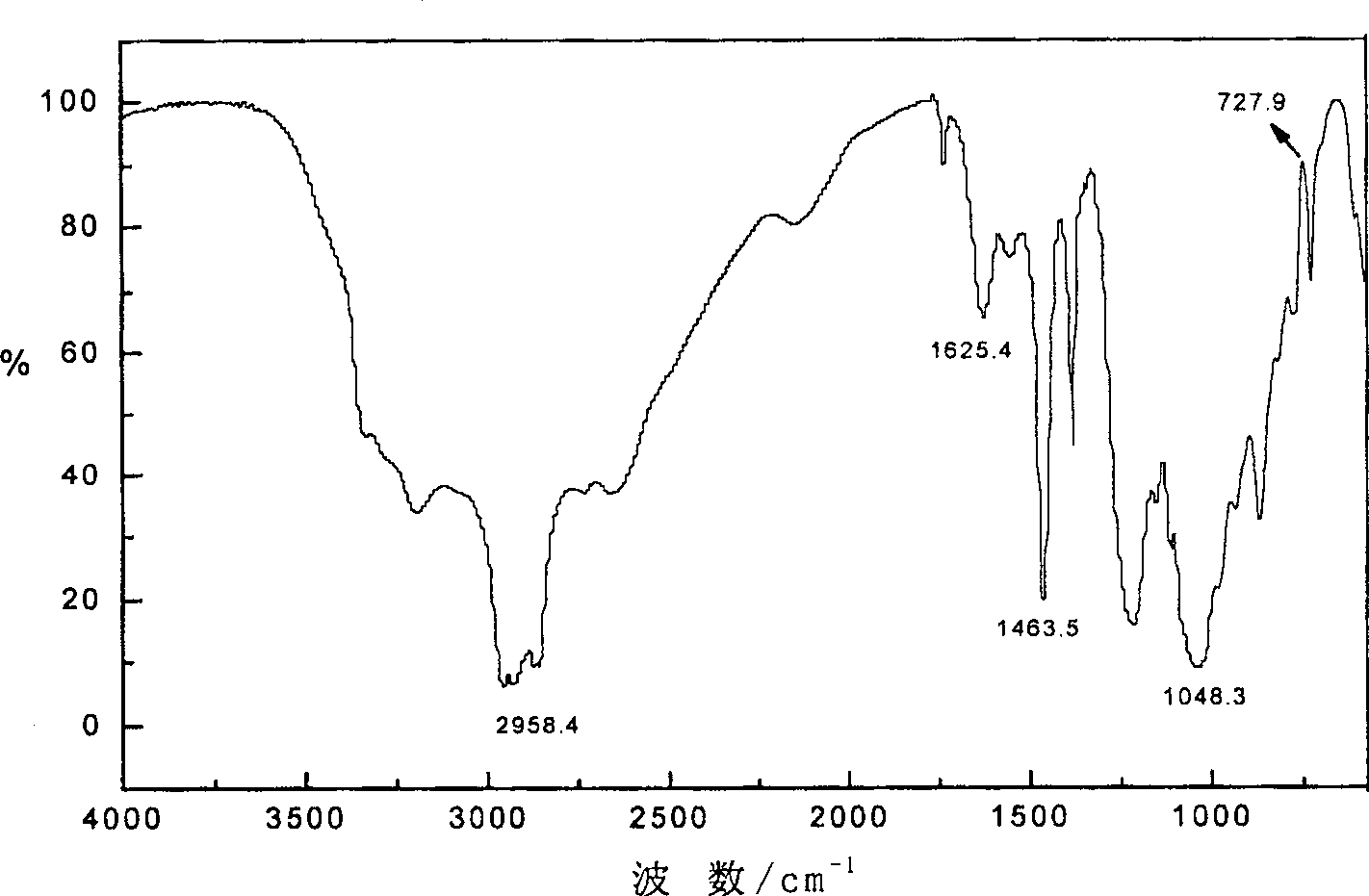

[0038] Take 0.3mol of phosphorus oxychloride and 200ml of tetrahydrofuran, stir and add 0.3mol of isooctyl alcohol at a temperature of 0±5°C, stir and add 0.3mol of isooctyl alcohol and 0.6mol of triethylamine after 3 hours, stir and add 0.33mol of triethylamine after another 3 hours Hydrazine hydrate, after 2 hours, heat up to 110±5°C to react for 1 hour, wash, dry, and purify. The obtained light yellow transparent liquid is the anti-wear additive diisooctylphosphorylhydrazide, code-named A2. A2 was added into N46 base oil at 0.50w%, and evaluated by four-ball tester, and the results are shown in Table 1;

example 3

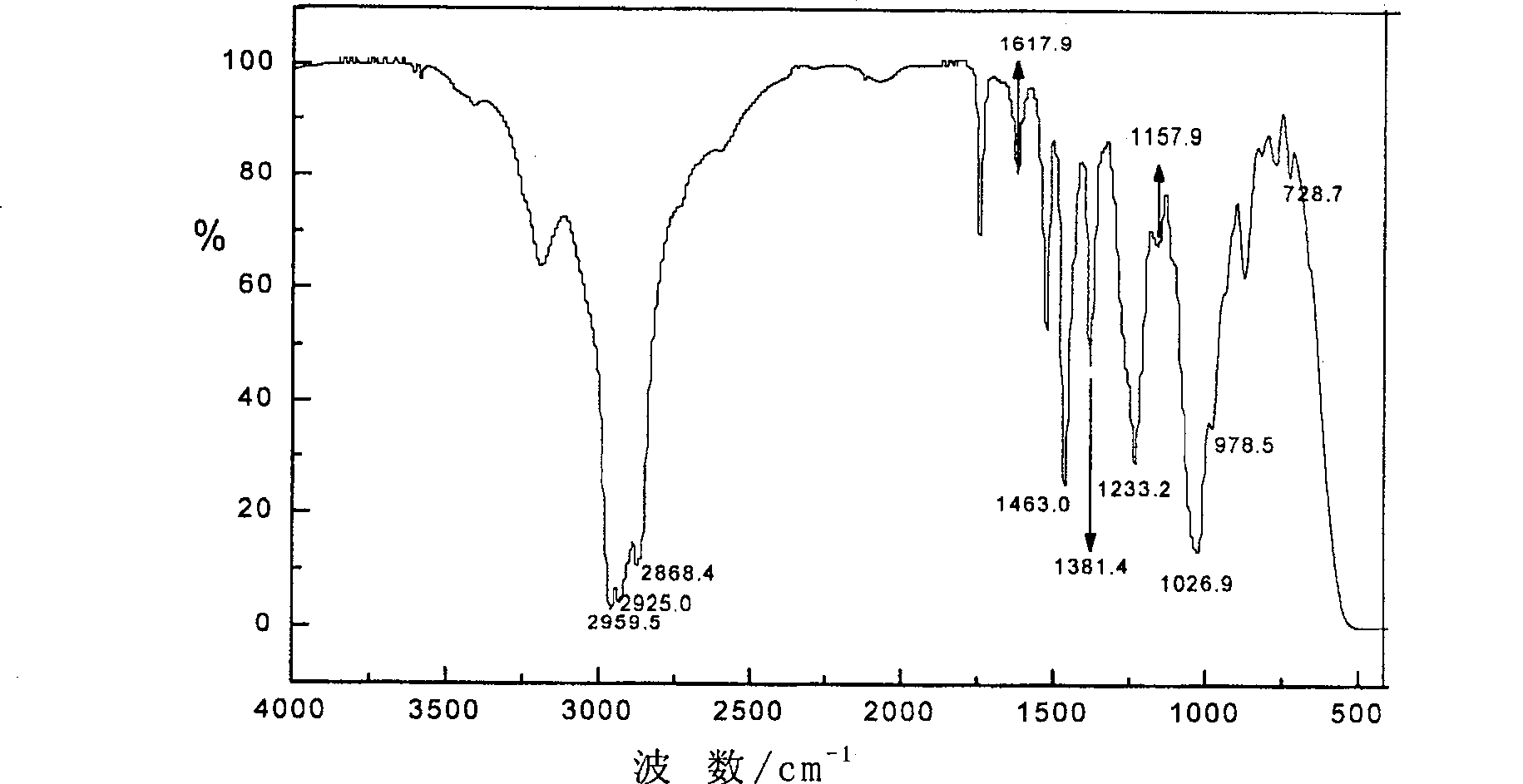

[0040] Take 0.3mol of phosphorus oxychloride and 150ml of ether, stir and add 0.3mol of n-butanol at a temperature of 0±5°C, stir and add 0.3mol of n-butanol and 0.4mol of triethylamine after 3 hours, and then separate after another 3 hours , Evaporate the solvent to obtain the intermediate phosphorus oxychloride. Put phosphorus oxychloride and 150ml toluene into a three-necked flask, add 0.3mol tertiary carbon primary amine (Primene 81-R) with a carbon number of 12, stir and add 0.3mol triethylamine, and heat up to 110±5°C after 2 hours React for 1 hour, wash, dry, and purify. The obtained yellow transparent liquid is the anti-wear additive di-n-butylphosphoryl lauryl ester, code-named A3. A3 was added into N46 base oil at 0.50w%, and evaluated by four-ball testing machine, and the results are shown in Table 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com