Soft color-changing real silk fabric and processing method thereof

A technology of silk fabrics and processing methods, applied in dyeing, animal fibers, textiles and papermaking, etc., can solve problems such as poor hand feeling of discolored silk fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

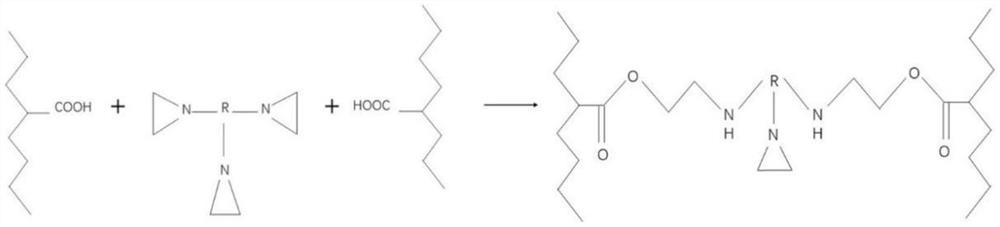

Method used

Image

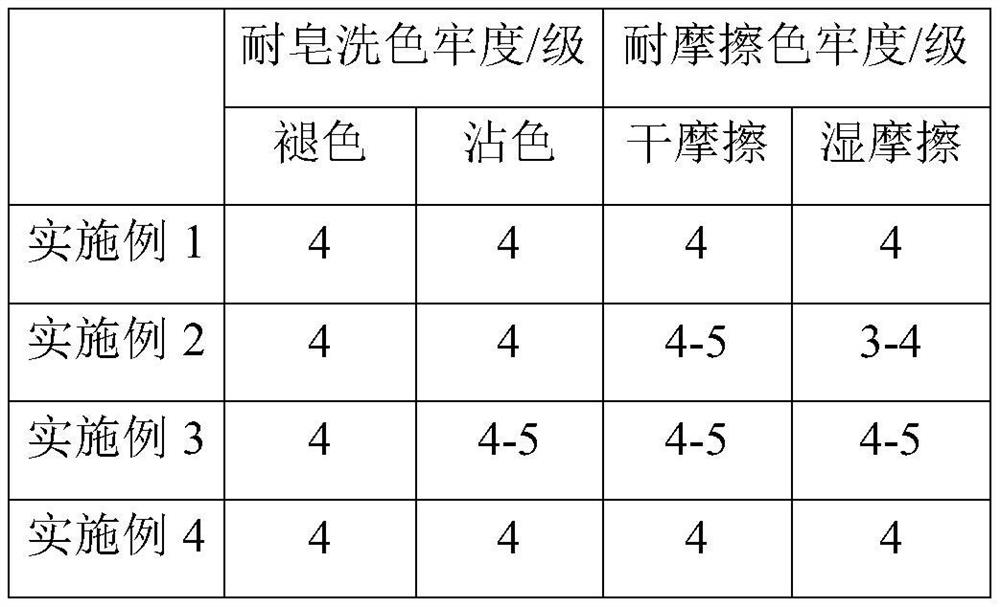

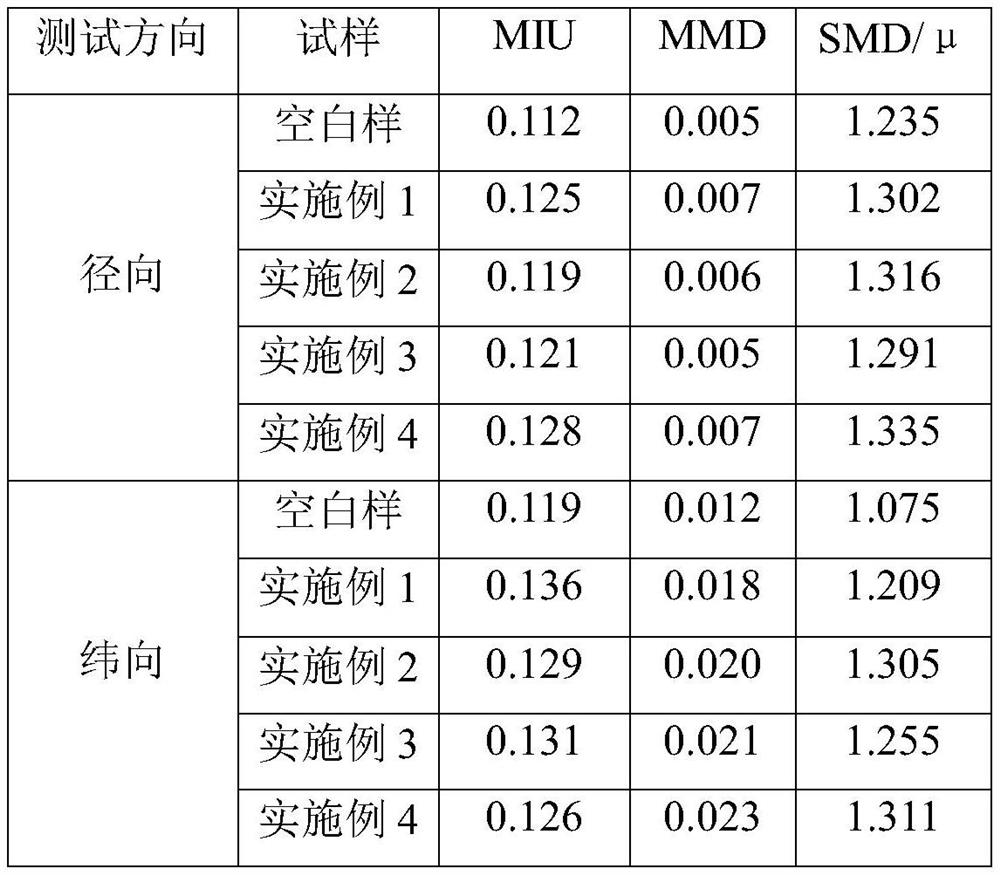

Examples

Embodiment 1

[0030] A kind of soft discoloration real silk fabric and its processing method, concrete steps are as follows:

[0031] (1) Temperature-sensitive color-changing dye solution: based on the mass fraction of 100%, 5% temperature-sensitive dye TPMN3102 royal blue, 3% isocyanate crosslinking agent XC-227, 10% water-based polyurethane emulsion, 0.5% defoamer AFE-3168, and more The volume is deionized water. According to the mass fraction of the dye solution, first dilute 3% of the cross-linking agent XC-227 with the same amount of deionized water, then dilute the 10% water-based polyurethane emulsion with the same amount of deionized water, mix them evenly, and add 0.5% Defoamer AFE-3168, add 68.5% deionized water, add 5% thermosensitive dye TPMN3102 sapphire blue and stir evenly.

[0032] (2) Dyeing: the silk fabric is dyed by the padding method, and the padding dyeing solution, pre-baking, baking, soaping, and drying are processed, wherein the padding dyeing solution and pre-baki...

Embodiment 2

[0035] A kind of soft discoloration real silk fabric and its processing method, concrete steps are as follows:

[0036] (1) Temperature-sensitive color-changing dye solution: based on 100% mass fraction, 5% temperature-sensitive dye TPMN3114 bright red, 2% isocyanate crosslinking agent XR-28-404, 10% water-based polyurethane emulsion, 0.5% defoamer AFE- 3168, the balance is deionized water. According to the mass fraction of the dye solution, first dilute 2% of the cross-linking agent XR-28-404 with an equal amount of deionized water, then dilute 10% of the water-based polyurethane emulsion with an equal amount of deionized water, mix them evenly, and add Add 0.5% defoamer AFE-3168, add 70.5% deionized water, add 5% thermosensitive dye TPMN3114 bright red and stir evenly.

[0037] (2) Dyeing: the silk fabric is dyed by the padding method, and the padding dyeing solution, pre-baking, baking, soaping, and drying are processed, wherein the padding dyeing solution and pre-baking a...

Embodiment 3

[0040] A kind of soft discoloration real silk fabric and its processing method, concrete steps are as follows:

[0041] (1) Temperature-sensitive color-changing dye solution: based on 100% mass fraction, 5% temperature-sensitive dye TPM3116 yellow, 5% water-based aziridine cross-linking agent XR-2500, 20% water-based polyurethane emulsion, 0.5% defoamer AFE- 3168, the balance is deionized water. According to the mass fraction of the dye solution, first dilute 5% of the cross-linking agent XR-2500 with an equal amount of deionized water, then dilute 20% of the water-based polyurethane emulsion with an equal amount of deionized water, mix them evenly, and add 0.5% Defoamer AFE-3168, add 44.5% deionized water, add 5% thermosensitive dye TPM3116 yellow and stir evenly.

[0042] (2) Dyeing: the silk fabric is dyed by the padding method, and the padding dyeing solution, pre-baking, baking, soaping, and drying are processed, wherein the padding dyeing solution and pre-baking are repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com