Ash-free anti-wear hydraulic oil

An anti-wear hydraulic oil, extreme pressure anti-wear technology, applied in the field of lubricating oil, can solve the problems of hydraulic system operation failure, poor thermal stability, corrosion of copper parts of plunger pumps, etc., to meet the requirements of low corrosion and anti-corrosion Abrasive requirements, the effect of good anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

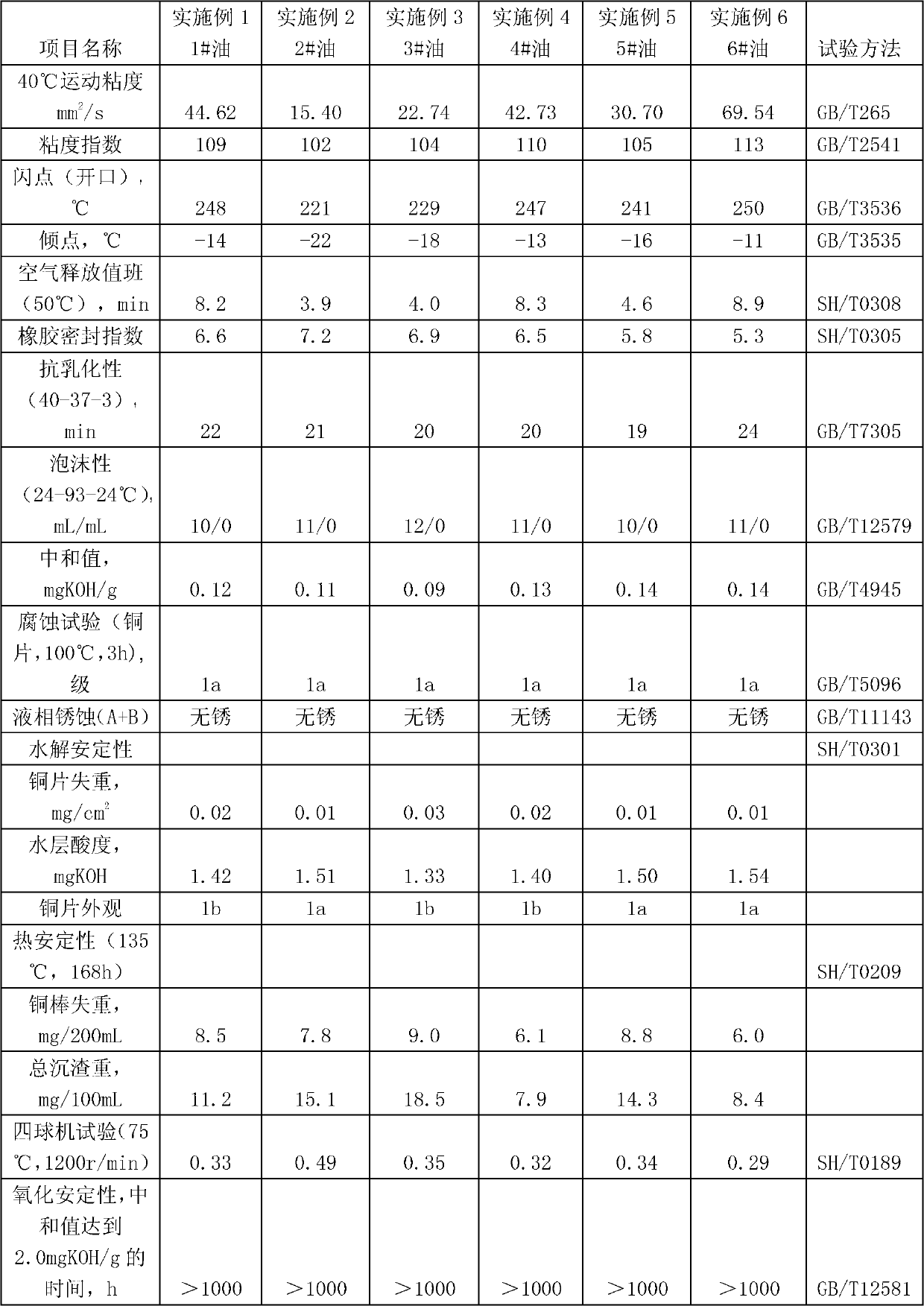

Embodiment 1

[0023] 1# Ashless anti-wear hydraulic oil, composed of the following components by weight:

[0024] base oil:

[0025] 95% ashless extreme pressure anti-wear additives for steam turbine oil with good oxidation stability and demulsibility: 3.0% AW-2 (S-P-N type): AW-3 (S-P type): AW-5 (P type ) Mixed by mass ratio 3:2:1 Metal deactivator: T551 and T561 mixed by mass ratio 1:1 0.09% Detergent and dispersant: DT-6 sulfurized calcium alkylphenate 0.01% Antioxidant: T531 Mixture with T501 at a mass ratio of 1:1 0.5% Antioxidant corrosion inhibitor: Dialkyl dithiophosphate 1.0% Rust inhibitor: Barium petroleum sulfonate T701 0.05% Viscosity index improver: OCP and PMA by mass ratio 15:2 composite agent 0.3% Antifoaming agent: methyl silicone oil 0.05%

[0026] The preparation method of the above-mentioned ashless anti-wear hydraulic oil composition, the steps are as follows:

[0027] Raise the temperature of the base oil to 85°C, control the stirring speed to 300r / min, stir for 3...

Embodiment 2

[0029] 2# Ashless anti-wear hydraulic oil, composed of the following components by weight:

[0030] base oil:

[0031] 94.9% ashless extreme pressure anti-wear additive for steam turbine oil with good oxidation stability and anti-emulsification properties:

[0032] AW-3 (S-P type): AW-5 (P type) mixture of mass ratio 5:2 2.6% metal deactivator: T551 and T561 mixture of mass ratio 2:1 0.8% detergent dispersant: DT -6 sulfurized alkylphenate calcium 0.03% Antioxidant: a mixture of T531 and T501 in a mass ratio of 1:2 0.6% antioxidative preservative: dialkyl dithiophosphate 0.5% antirust agent: basic dinonyl Barium naphthalene sulfonate T705 0.06% Viscosity index improver: OCP and PMA composite agent at a mass ratio of 9:2 0.5% Anti-foaming agent: methyl silicone oil 0.01%

[0033] The preparation method of the above-mentioned ashless anti-wear hydraulic oil composition, the steps are as follows:

[0034] Raise the temperature of the base oil to 75°C, control the stirring spee...

Embodiment 3

[0036] 3# Ashless anti-wear hydraulic oil, composed of the following components by weight:

[0037] base oil:

[0038] Turbine oil with good oxidation stability and emulsification resistance 92% ashless extreme pressure anti-wear additive: AW-3 (S-P type) 3% metal deactivator: T551 and T561 are mixed in a mass ratio of 1:2 The mixture of 2% detergent and dispersant: DT-6 sulfurized alkylphenate calcium 0.05% antioxidant: the mixture of T531 and T501 at a mass ratio of 2:1 1.0% antioxidant preservative: dialkyl dithiophosphate 0.82 % Antirust agent: Dodecenylsuccinic acid T746 0.08% Viscosity index improver: Compound agent of OCP and SD at a mass ratio of 11:2 1.0% Antifoaming agent: Methyl silicone grease 0.05%

[0039] The preparation method of the above-mentioned ashless anti-wear hydraulic oil composition, the steps are as follows:

[0040] Raise the temperature of the base oil to 80°C, control the stirring speed to 350r / min, stir for 4 hours, add antioxidants, anti-oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com