Lubricant composition for double-clutch gearbox

A lubricating oil composition and dual-clutch technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of low transmission efficiency and poor operability, and achieve the effects of excellent performance, low production cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Lubricating oil composition (I), it comprises: 80.0wt% hydroisomerization dewaxing III group base oil No. 4 oil (component A); 10.0wt% polymethacrylate (component B); 1.5 wt% polyalpha-olefin (component C); 0.5 wt% trialkyldithiophosphate (component D); 0.25 wt% monooctadecyl phosphonate, 0.25 wt% boronated mono Glyceryl oleate (component E); 0.4wt% bis-nonyldiphenylamine, 0.4wt% di-n-butyl dithiocarbamate diisooctyl (component F); 3.0wt% molecular weight 2800 Polyisobutenyl succinimide, 3.0 wt% polyisobutenyl succinimide (component G) of boron-phosphating molecular weight 960; 0.5 wt% sulfurized alkyl salicylic acid calcium phosphate (component H); 0.2% by weight of thiadiazole stearylamine formaldehyde condensate (component I). The lubricating oil composition (II) is the same as the composition (I) except that 0.5wt% trialkyl dithiophosphate of component (D) is replaced by 0.5wt% trialkyl monothiophosphate. Lubricating oil composition (III) is the same as compositio...

Embodiment 2

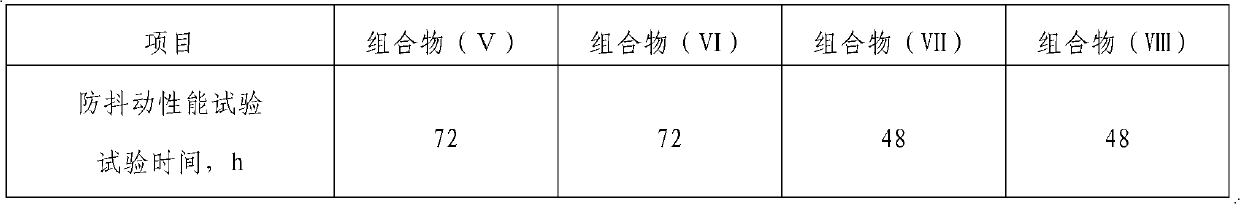

[0027] Lubricating oil composition (V), it comprises: 94.1wt% hydroisomerization dewaxing III group base oil No. 6 oil (component A); 3.0wt% polymethacrylate (component B); 1.0 wt% polyalpha-olefin (component C); 0.2 wt% acid phosphate amine salt (component D); 0.20 wt% monooctadecyl phosphonate, 0.20 wt% borated dioleate Triol ester (component E); 0.10wt% bis-octyl diphenylamine, 0.10wt% di-n-octyl dithiocarbamate diisooctyl ester (component F); 0.5wt% boron phosphorus with molecular weight 2800 The polyisobutenyl succinimide of 0.5wt% molecular weight 960 polyisobutenylsuccinimide (component G); 0.05wt% calcium alkylbenzene sulfonate (component Part H); 0.05% by weight of thiadiazole dodecylamine formaldehyde condensate (component I). Lubricating oil composition (VI) removes component (E) 0.20wt% monooctadecyl phosphonate, 0.20wt% borated dioleate glycerol ester is replaced by 0.20wt% dioctadecylphosphine Ester, 0.20wt% borated glycerol dioleate instead, the rest are the s...

Embodiment 3

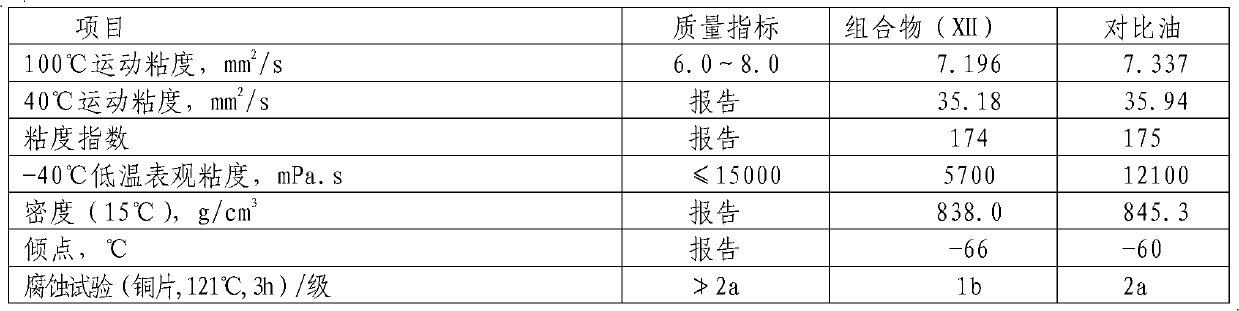

[0032] Additive composition (IX), it comprises: the polyalpha-olefin synthetic oil PAO-4 of 65.6wt%, the diester synthetic oil (component A) of 16.4wt%; The polymethacrylate (component A) of 9.9wt% B); 0.1 wt% polyalphaolefin (component C); 0.05 wt% trialkyl dithiophosphate, 0.40 wt% acid phosphate amine salt, 0.05 wt% dialkyl dithiophosphate Acrylates (component D); 0.10 wt% monooctadecyl phosphonate, 0.10 wt% borated glycerol monooleate (component E); 0.25 wt% dioctyl diphenylamine, 0.25wt% of diisooctyl di-n-octyl dithiocarbamate (component F); 3.0wt% of borophosphated polyisobutenyl succinimide with a molecular weight of 2800, 3.0wt% of polyisobutenyl succinimide with a molecular weight of 960 Isobutenyl succinimide (component G); 0.5 wt% of sulfurized alkylphenate calcium (component H) with a base value of 400mgKOH / g; 0.2 wt% of thiadiazole dodecylamine formaldehyde condensate (component I). The evaluation results of composition (IX) are listed in Table 3.

[0033] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com