Process for producing polyisobutene succinimide ashless dispersant by free radical method

A technology of polyisobutylene succinimide and ashless dispersant, which is applied in the direction of additives, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of high energy consumption, high reaction temperature, and prolonged reaction cycle, and achieve simplified process Steps, reduce the reaction temperature, shorten the effect of the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

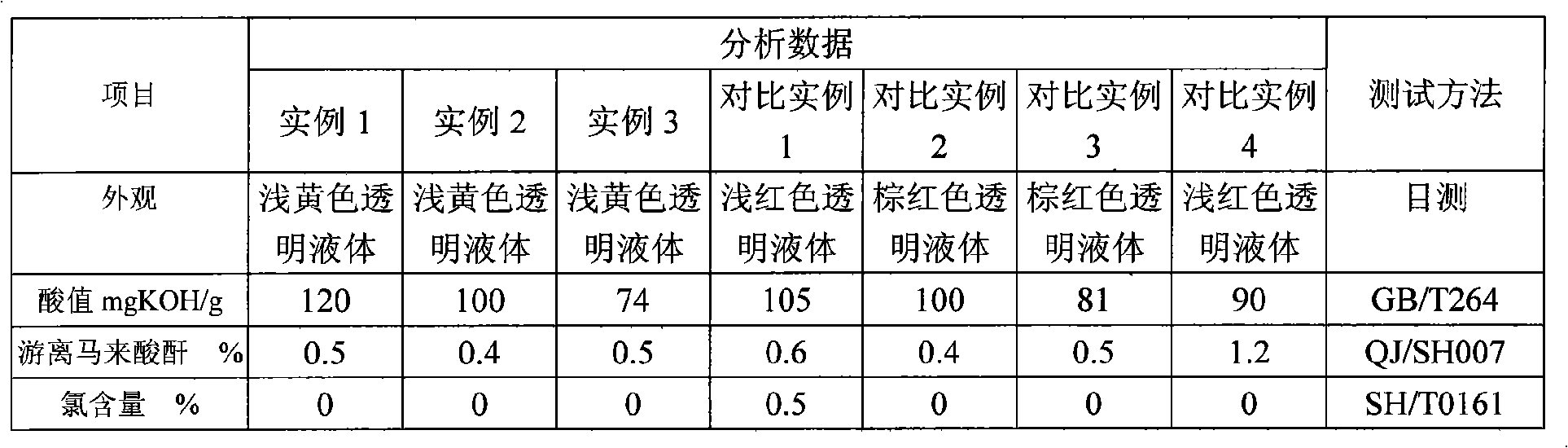

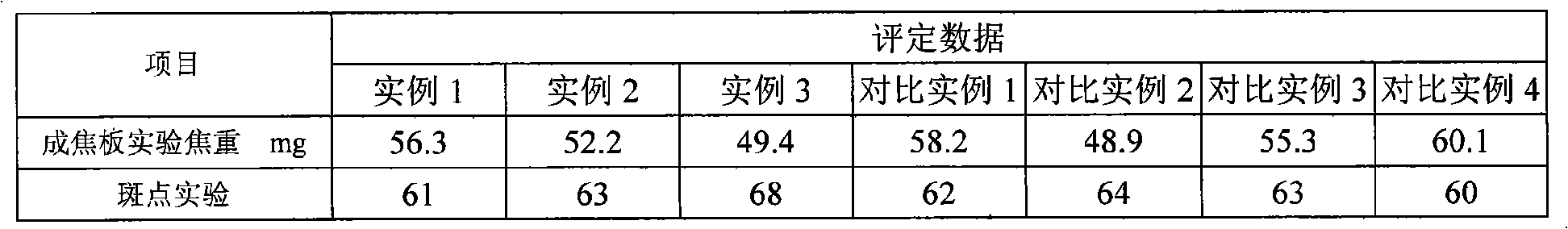

example 1

[0023] Put 300g of highly active polyisobutene with an average molecular weight of 1000 produced by Jihua in a three-necked flask equipped with a stirring, thermometer and reflux condenser, heat up to 100-150°C, add 38g of maleic anhydride, and keep stirring for 0.5- For 1 hour, mix the materials evenly, add 3g of di-tert-butyl peroxide dropwise at a temperature of 100-150°C (dropping is completed within 0.5-3 hours), raise the temperature to 160-200°C, react for 3 hours, and sampling is in progress Control analysis, product acid value 120mgKOH / g, free maleic anhydride 0.5% (weight), finishes reaction, and product is filtered to obtain polyisobutylene succinic anhydride.

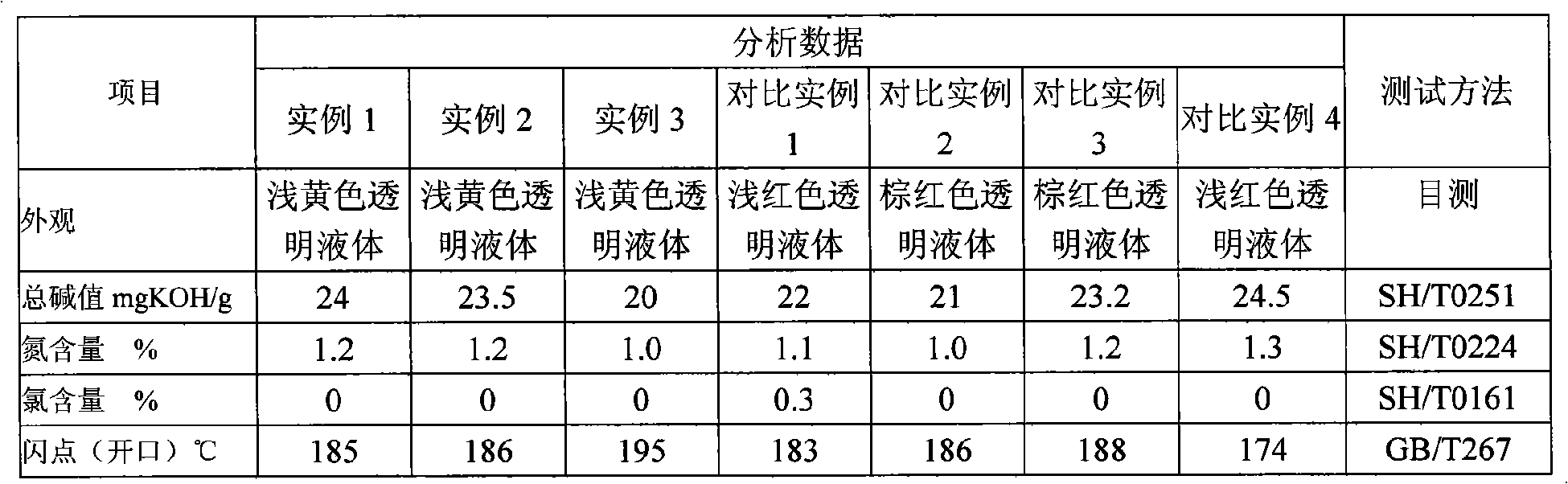

[0024] Add 200g of polyisobutylene succinic anhydride synthesized above into a three-necked flask, then add 200g of 150SN base oil to dilute and stir evenly; raise the temperature to 90-130°C, add 14g of tetraethylenepentamine dropwise for amidation reaction, tetraethylenepentamine The dropping time is 2 hou...

example 2

[0026] Put 300g of highly active polyisobutene with an average molecular weight of 1300 produced by Jihua in a three-necked flask equipped with a stirring, thermometer and reflux condenser, heat up to 100-150°C, add 29g of maleic anhydride, and keep stirring for 0.5- For 1 hour, mix the materials evenly, add 3g of di-tert-butyl peroxide dropwise at a temperature of 100-150°C (dropping is completed within 0.5-3 hours), raise the temperature to 160-200°C, react for 3 hours, and sampling is in progress Control analysis, product acid value 100mgKOH / g, free maleic anhydride 0.4% (weight), finishes reaction, and product is filtered to obtain polyisobutylene succinic anhydride.

[0027] Add 200g of polyisobutylene succinic anhydride synthesized above into a three-necked flask, then add 200g of 150SN base oil to dilute and mix evenly; raise the temperature to 90-130°C, add 14g of tetraethylenepentamine dropwise for amidation reaction, tetraethylenepentamine The dropping time is 2 hour...

example 3

[0029] Put 300g of highly active polyisobutylene with an average molecular weight of 2300 produced by Jihua in a three-necked flask equipped with a stirring, thermometer and reflux condenser, heat up to 100-150°C, add 22g of maleic anhydride, and keep stirring for 0.5- For 1 hour, mix the materials evenly, add 3g of di-tert-butyl peroxide dropwise at a temperature of 100-150°C (dropping is completed within 0.5-3 hours), raise the temperature to 160-200°C, react for 3 hours, and sampling is in progress Control analysis, product acid value 74mgKOH / g, free maleic anhydride 0.5% (weight), finishes reaction, and product is filtered to obtain polyisobutylene succinic anhydride.

[0030] Add 200g of polyisobutylene succinic anhydride synthesized above into a three-necked flask, then add 200g of 150SN base oil to dilute and mix evenly; raise the temperature to 90-130°C, add 12g of tetraethylenepentamine dropwise for amidation reaction, tetraethylenepentamine The dropping time is 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com