A drilling fluid and a method of improving fluid loss reduction performance of the drilling fluid

A drilling fluid and base fluid technology, applied in the field of drilling fluid, can solve the problems of high pour point and easy hydrolysis of ester groups, and achieve the effects of low pour point, good lubricating performance and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 160g of isooctyl alcohol into 300g of base liquid A (cottonseed oil biodiesel), add 9.0g of catalyst p-toluenesulfonic acid under normal pressure under stirring, after the addition is completed, feed N under normal pressure 2 , heated to 150°C, stirred and reacted for 4 hours, and washed with water to obtain base liquid B.

Embodiment 2

[0047] Add 106g of isoamyl alcohol into 300g of base liquid C (soybean oil biodiesel), add 6.0g of catalyst tetrabutyl titanate under normal pressure under stirring, after the addition is complete, feed N under normal pressure 2 , heated to 120°C, stirred and reacted for 5 hours, and washed with water to obtain the base liquid D.

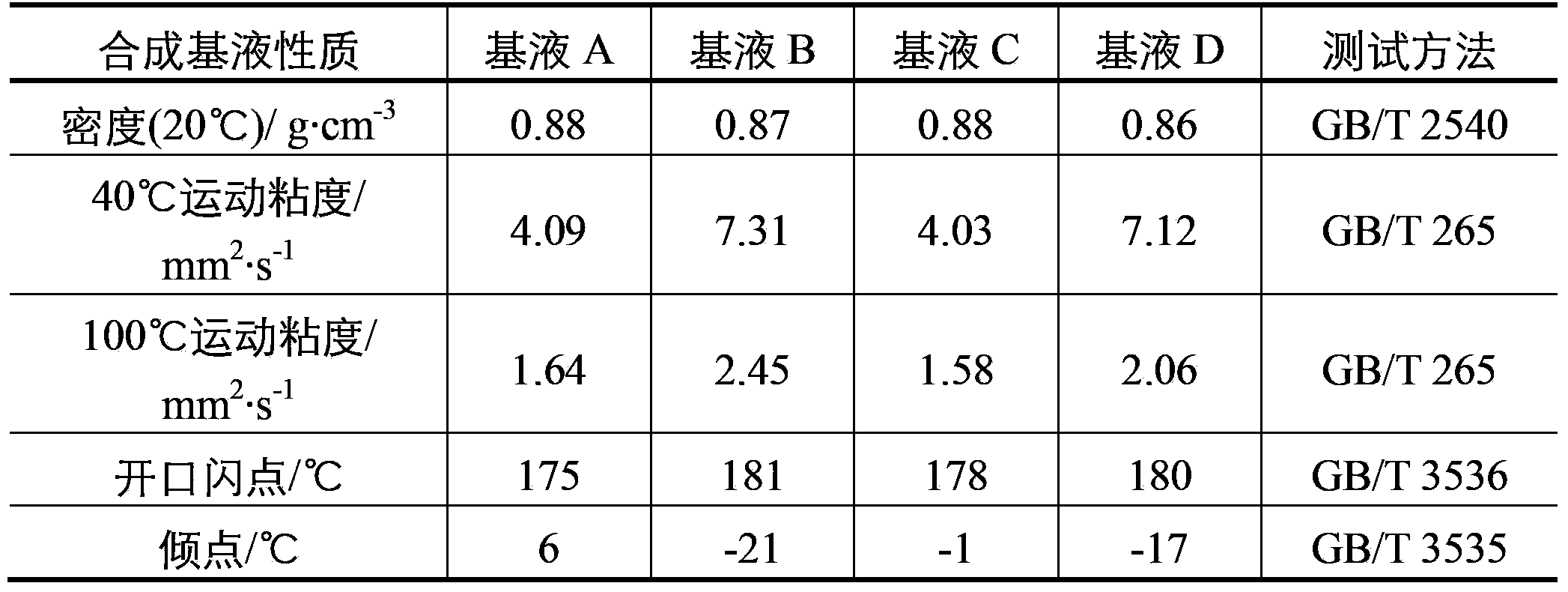

[0048] The physical and chemical properties of base fluids A, B, C, and D are shown in Table 1.

[0049] Table 1 Physicochemical properties of base fluids A, B, C, and D

[0050]

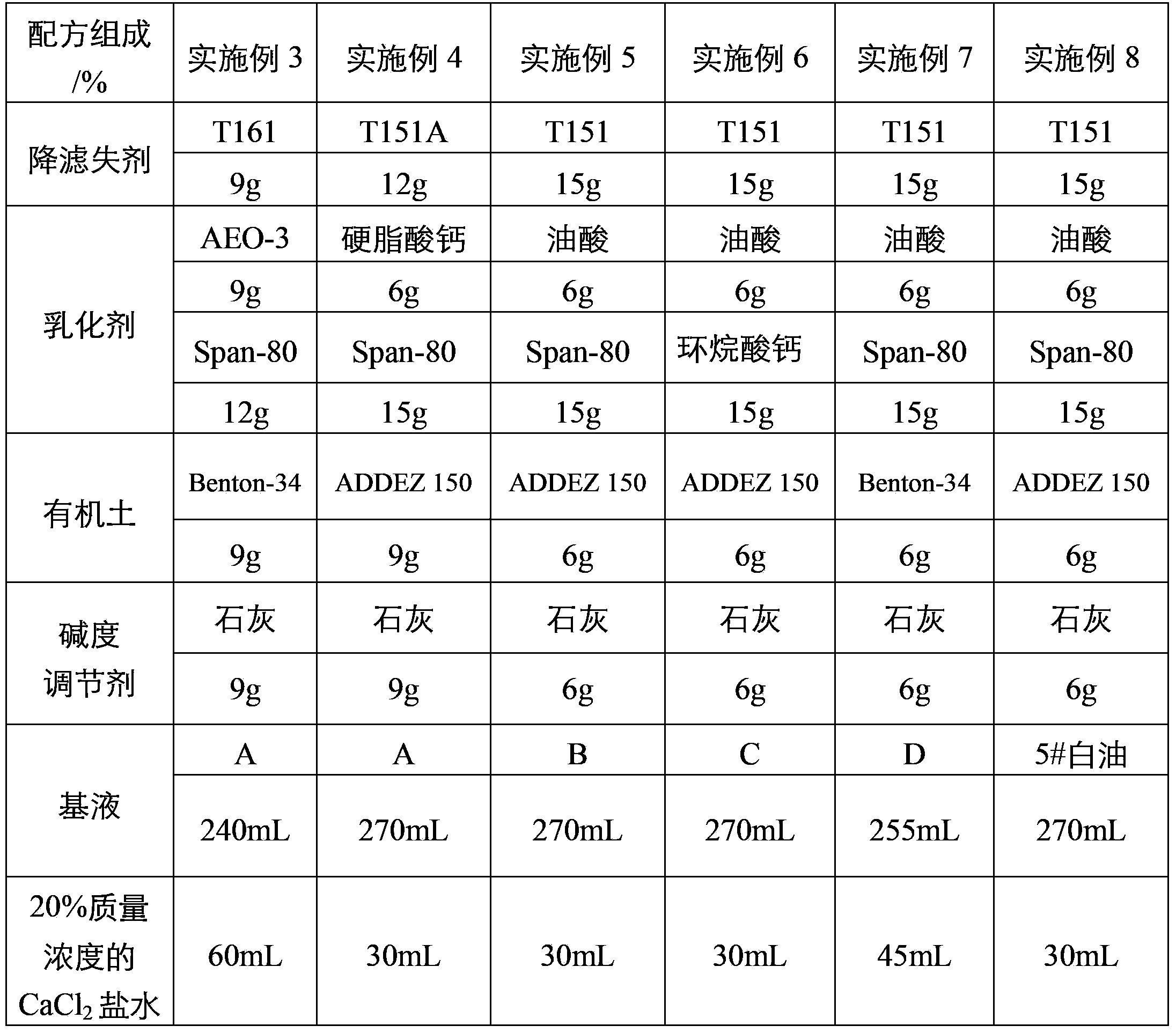

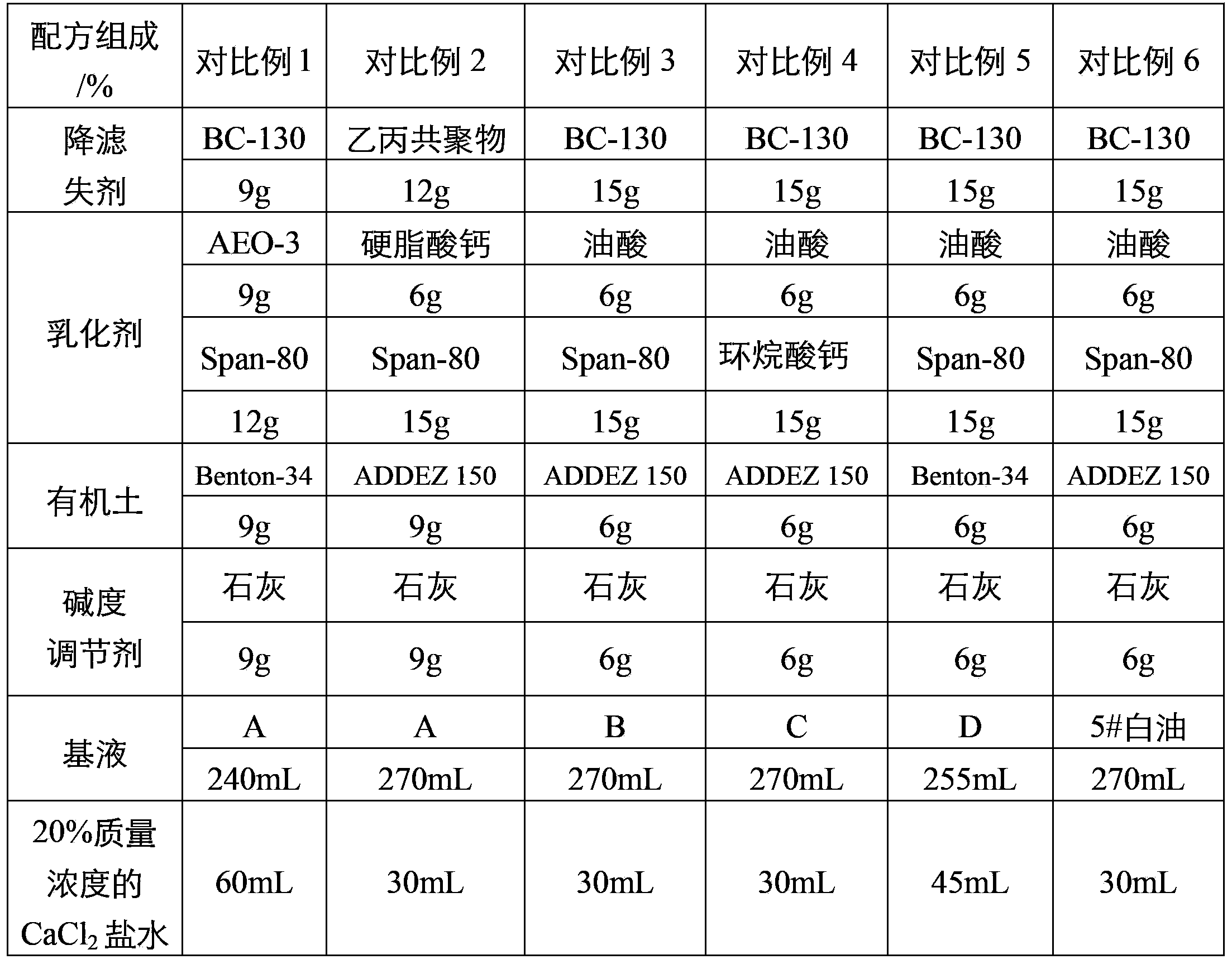

[0051] Examples 3-8 and comparative examples 1-6 of drilling fluid

[0052] Mix the base liquid with polyisobutylene succinimide, emulsifier, and organic soil according to the formulations in Tables 2 and 3, and stir at a speed of 11000r / min for 10min, then add alkalinity regulator and inorganic salt water, and stir at 11000r / min Examples 3-8 and Comparative Examples 1-6 of the drilling fluid were prepared after stirring at a speed of 30 min.

[0053] The embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com