Additive composite of lubricating oil for industrial gears

A technology of additives and compositions, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of unstable base oil quality, unqualified anti-emulsification performance, etc., and achieve the effect of improving anti-emulsification performance and improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

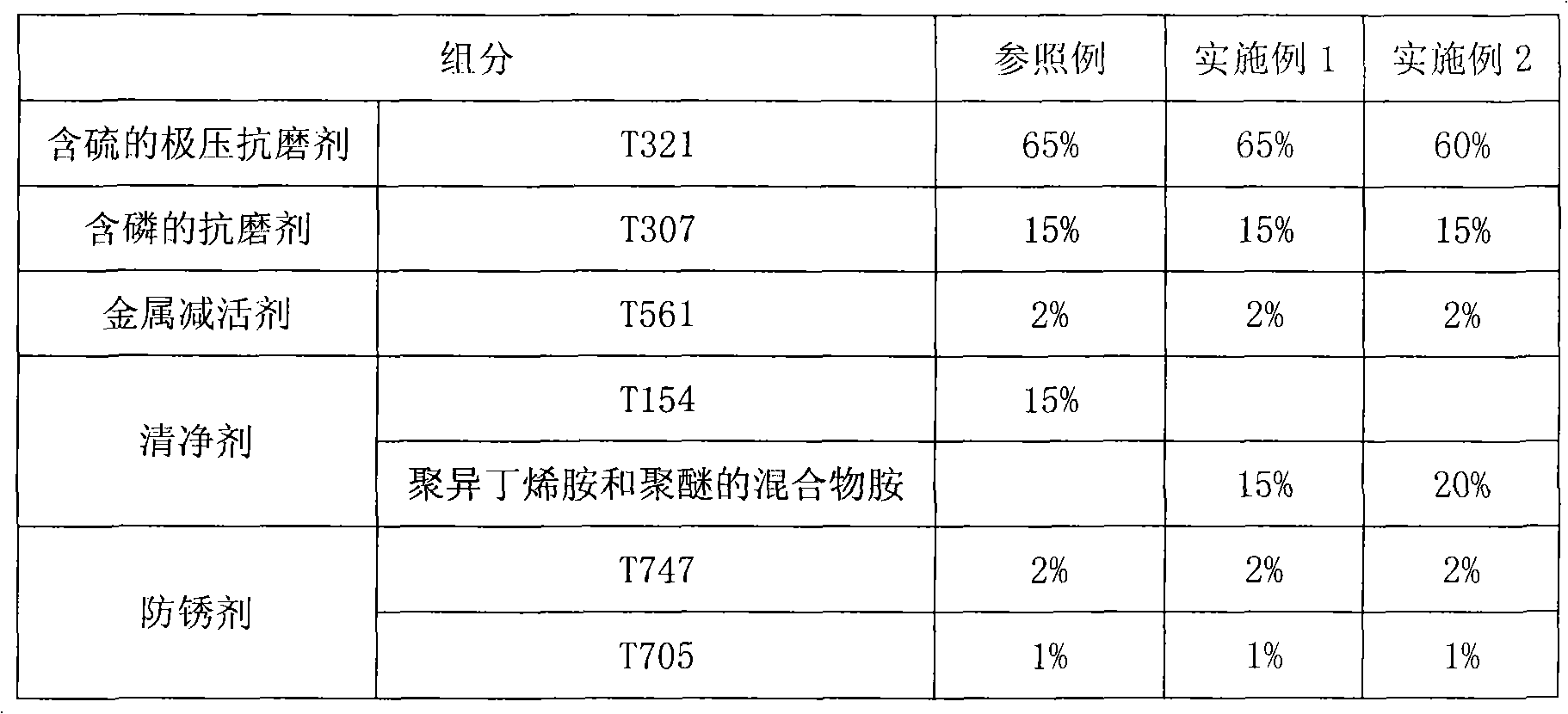

Embodiment 1

[0012] Add 65 parts of sulfurized isobutylene (T321) extreme pressure antiwear agent into the enamel mixing kettle with agitator, then add 15 parts of phosphorothioate and its amine salt derivatives (T307) antiwear agent, 2 parts of alkenyl Add succinate (T747) and 1 part of dinonyl naphthalene sulfonate barium salt (T705) rust inhibitor into the blending kettle, keep the temperature of the kettle between 60 and 70°C, and stir continuously for 4 hours; finally, Add 2 parts of thiadiazole derivatives (T561) metal deactivator and 15 parts of polyisobutene amine and polyether mixture amine detergent into the mixing tank, keep the temperature of the tank between 40 and 50 °C, and continuously stir for 2 Hours until the mixture is completely dissolved and becomes uniformly transparent.

Embodiment 2

[0014] Add 60 parts of sulfurized isobutylene (T321) extreme pressure antiwear agent into the enamel mixing kettle with agitator, then add 15 parts of phosphorothioate and its amine salt derivatives (T307) antiwear agent, 2 parts of alkenyl Add succinate (T747) and 1 part of dinonyl naphthalene sulfonate barium salt (T705) rust inhibitor into the blending kettle, keep the temperature of the kettle between 60 and 70°C, and stir continuously for 4 hours; finally, Add 2 parts of thiadiazole derivatives (T561) metal deactivator and 20 parts of polyisobutylene amine and polyether mixture amine detergent into the mixing tank, keep the temperature of the tank between 40 and 50 °C, and continuously stir for 2 Hours until the mixture is completely dissolved and becomes uniformly transparent.

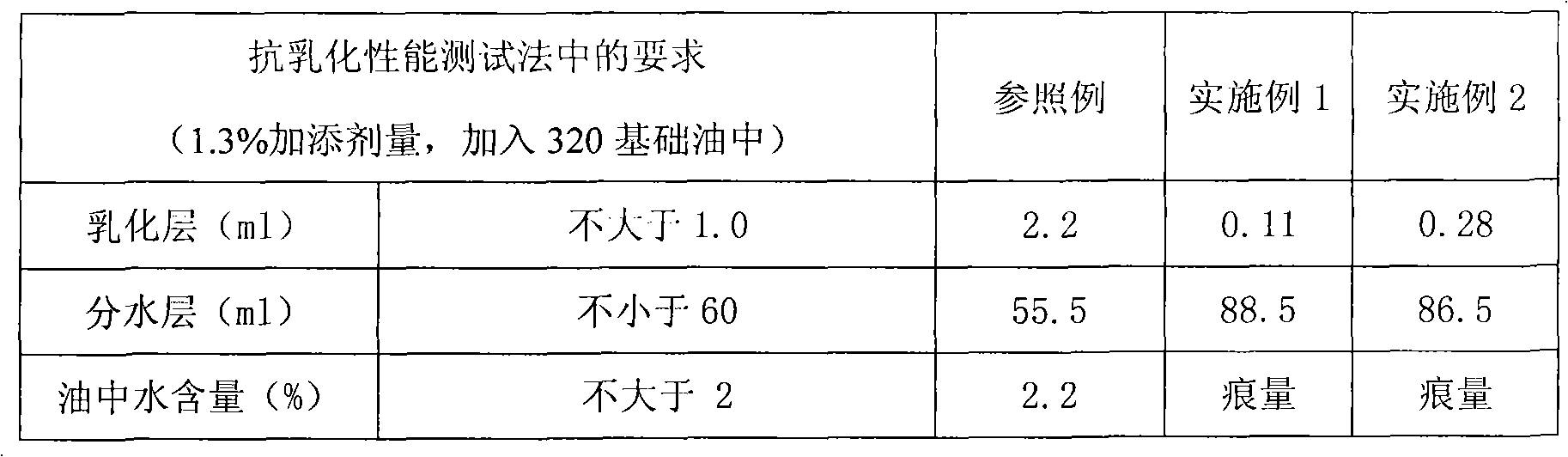

[0015] (performance evaluation)

[0016] In order to screen the additive components and the additive composition, the present invention adopts various test methods in the laboratory for simulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com