Wear-resistant hydraulic-oil additive composition with excellent anti-emulsifying property

A technology of anti-wear hydraulic oil and additives, applied in additives, lubricating compositions, petroleum industry, etc., can solve problems such as unqualified anti-emulsification performance and unstable base oil quality, and achieve improved anti-emulsification performance and excellent anti-emulsification performance , Improve the effect of transparency

Active Publication Date: 2010-11-10

北京泽华凯泰科技发展有限公司

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, due to changes in refining processes and raw materials, the quality of base oils has become increasingly unstable, which poses a severe challenge to lubricating oil manufacturers and additive suppliers. As a lubricating oil additive, since polyisobutylene succinimide and basic calcium sulfonate, magnesium detergent and dispersant are used as detergent and dispersants, the phenomenon of unqualified anti-emulsification performance often occurs when base oil is blended. Therefore, the development It is of great significance to develop an additive composition with broad-spectrum base oil adaptability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

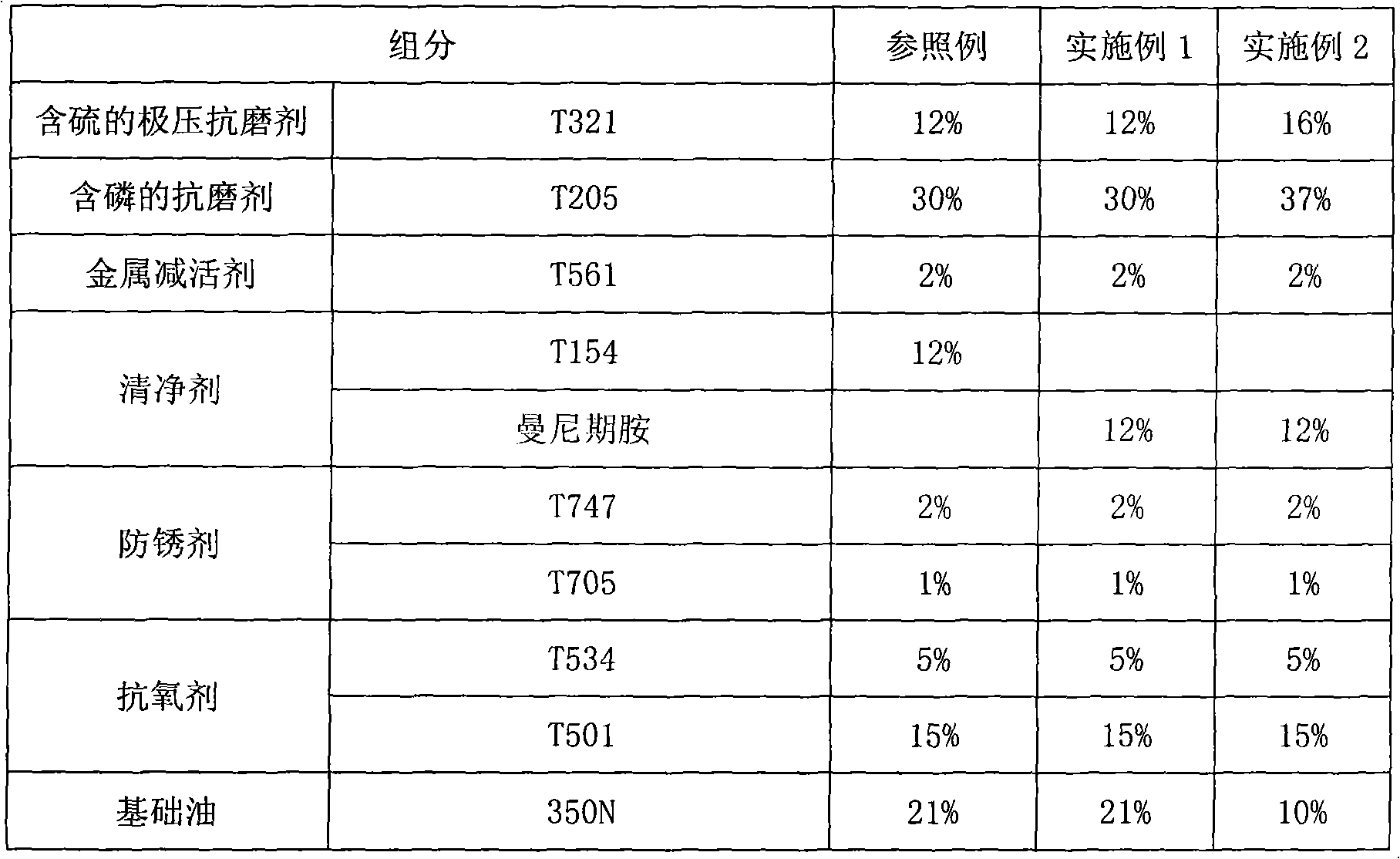

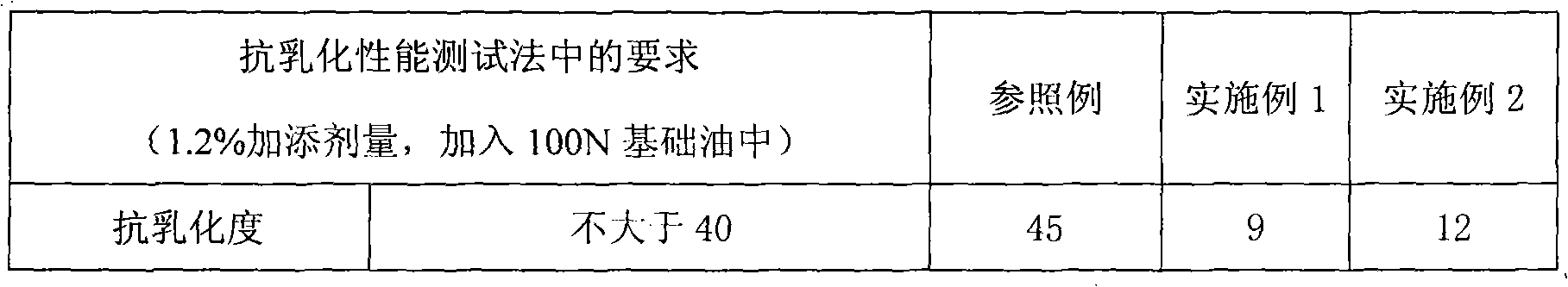

The invention relates to a wear-resistant hydraulic-oil additive composition with excellent anti-emulsifying property for a lubricating oil additive composition of a hydraulic transmission system, belonging to the technical field of a lubricating oil additive. The wear-resistant hydraulic-oil additive composition comprises an extreme-pressure anti-wear agent containing sulfur, an anti-wear agent containing phosphorus, a metal deactivator, a detergent, an anti-rusting agent and an antioxidant. The raw material contains the following components in percentage by weight: 5-20 % of extreme-pressure anti-wear agent containing sulfur, 20-55% of anti-wear agent containing sulfur, 1-10% of metal deactivator, 5-20% of detergent, 2-5% of anti-rusting agent, 12-25% of antioxidant, and the balance of base oil, and the sum of the percentage of all the components is 100%. The additive composition adopts the existing mannich amine detergent usually used in the gasoline detergent to replace polyisobutylene succinimide, alkaline calcium sulfonate and a magnesium detergent used in the traditional lubricating oil additive, and obviously improves the anti-emulsifying property of industrial wear-resistant hydraulic oil.

Description

An anti-wear hydraulic oil additive composition with excellent anti-emulsification performance technical field The invention relates to an anti-wear hydraulic oil additive composition with excellent anti-emulsification performance, is a lubricating oil additive composition used in a hydraulic transmission system, and belongs to the technical field of lubricating oil additives. Background technique At present, due to changes in refining processes and raw materials, the quality of base oils has become increasingly unstable, which poses a severe challenge to lubricating oil manufacturers and additive suppliers. As a lubricating oil additive, since polyisobutylene succinimide and basic calcium sulfonate, magnesium detergent and dispersant are used as detergent and dispersants, the phenomenon of unqualified anti-emulsification performance often occurs when base oil is blended. Therefore, the development It is of great significance to develop an additive composition with broad-s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M141/10C10M133/04C10N40/08C10N40/04

Inventor 任宝东

Owner 北京泽华凯泰科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com