Graphene-fullerene-like molybdenum disulfide compounded lubricating oil additive and preparation method thereof

A technology of fullerene molybdenum disulfide and lubricating oil additives, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., to achieve the effects of improving dispersion and stability, improving anti-wear and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

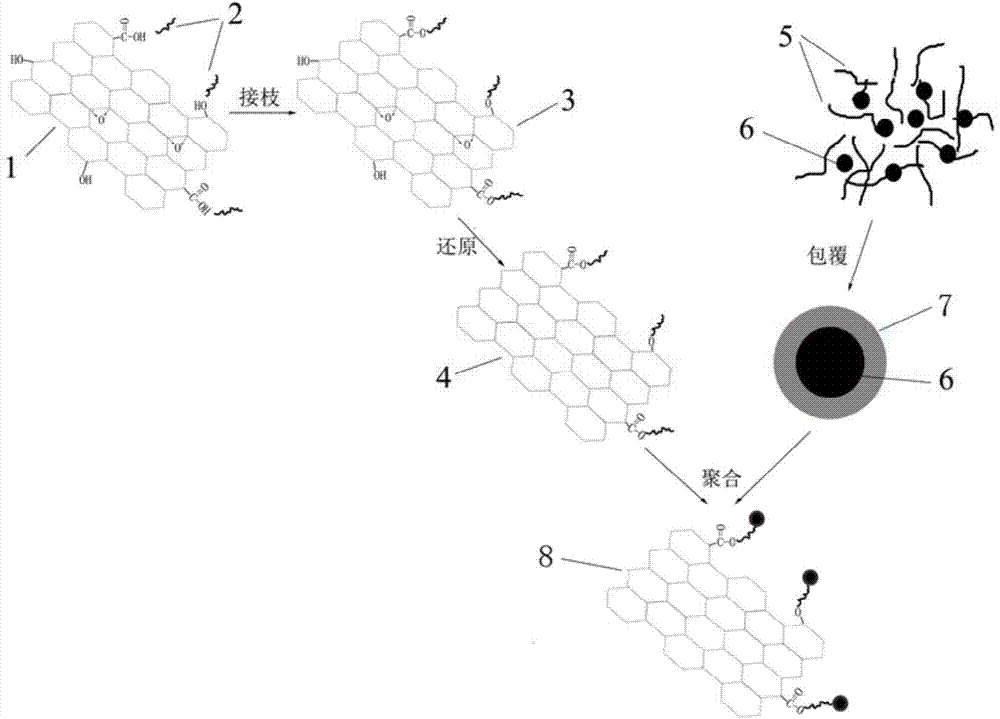

Embodiment 1

[0041] 1) Measure 80mL of N-N dimethylformamide and 20mL of deionized water, mix well, add 0.1g of graphene oxide 1 particles, and disperse for 1h with ultrasound to form a uniformly dispersed graphene oxide suspension, Then add 0.1g of lipophilic polymer chain KH-5702 to the suspension, and carry out chemical grafting in a water bath at 40°C and magnetic stirring for 2 hours, wherein the stirring speed is 400r / min; after the grafting is completed, Adopt high-speed centrifuge to carry out centrifugation, rotating speed is 2000r / min, and adopt dehydrated alcohol to carry out repeated cleaning and centrifugation, after drying, obtain grafted graphene oxide 3;

[0042] 2) Add 0.1 g of grafted graphene oxide 3 to 1000 mL of deionized water, stir evenly, disperse by ultrasonic for 3 h, and then add 0.3 mL of hydrazine hydrate to reduce the grafted graphene oxide 3 to remove its The hydroxyl groups and oxygen-containing groups on the surface were reacted in a water bath at 80°C for ...

Embodiment 2

[0049] 1) Measure 85mL of N-N dimethylformamide and 15mL of deionized water, mix well, add 0.3g of graphene oxide 1 particles, and disperse for 2h with ultrasound to form a uniformly dispersed graphene oxide suspension, Then add 0.3g of lipophilic polymer chain KH-5702 to the suspension, and carry out chemical grafting in a water bath at 45°C and magnetic stirring for 3 hours, wherein the stirring speed is 400r / min; after the grafting is completed, Adopt high-speed centrifuge to carry out centrifugation, the rotating speed is 3000r / min, and adopt dehydrated alcohol to carry out repeated cleaning and centrifugation, after drying, obtain grafted graphene oxide 3;

[0050] 2) Add 0.3 g of grafted graphene oxide 3 to 1000 mL of deionized water, stir evenly, and disperse it by ultrasonic for 4 h, then add 0.6 mL of hydrazine hydrate to reduce the grafted graphene oxide 3 to remove its The hydroxyl groups and oxygen-containing groups on the surface were reacted in a water bath at 90...

Embodiment 3

[0057] 1) Measure 90mL of N-N dimethylformamide and 10mL of deionized water, mix well, add 0.5g of graphene oxide 1 particles, and disperse for 3h with ultrasound to form a uniformly dispersed graphene oxide suspension, Then add 0.5g of lipophilic polymer chain KH-5702 to the suspension, and carry out chemical grafting for 4 hours in a water bath at 50°C and magnetic stirring, wherein the stirring speed is 500r / min; after the grafting is completed, Adopt high-speed centrifuge to carry out centrifugation, the rotating speed is 5000r / min, and adopt dehydrated alcohol to carry out repeated cleaning and centrifugation, after drying, obtain grafted graphene oxide 3;

[0058] 2) Add 0.5 g of grafted graphene oxide 3 to 1000 mL of deionized water, stir evenly, and disperse it by ultrasonic for 5 h, then add 0.9 mL of hydrazine hydrate to reduce the grafted graphene oxide 3 to remove its Hydroxyl and oxygen-containing groups on the surface were reacted in a water bath at 100°C for 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com